- Home

- Companies

- ML Spirals

- Products

ML Spirals products

Grit Separation

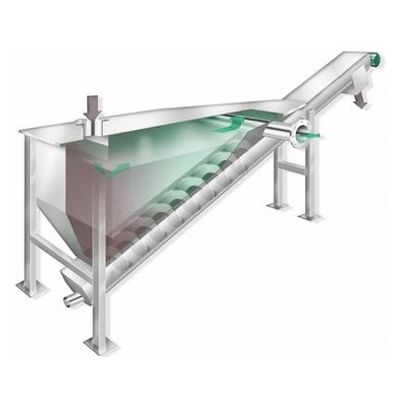

ML Spirals - Grit Classifier

An effective classifier of the screw type which is manufactured in five standard sizes and is used for automatic removal of grit from grit traps or other sedimented particles with relative high sedimentation velocity.

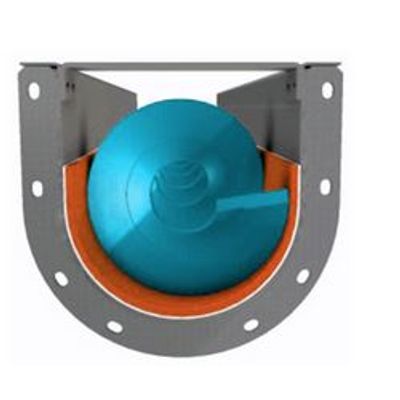

ML-Spirals - Grit Washer

A compact grit washer carried out by a cyclone with a prewash and Grit Dewaterer. The grit separation tank is designed to be as small as possible but with high efficiency and with separation of grit down to a grain size of 0.20 mm. It is equipped with necessary connections for cleaning water and drainage. There is an inspection door and also the valves necessary for automatic operation.

ML Screw Conveyor Spare Parts

ML / Spaans - Intermediate Bearings

ML / Spaans BHS intermediate bearings come in many shapes and sizes. By applying a flexible coupling that has been specially designed by ML / Spaans BHS, larger distances between bearing assemblies are possible.

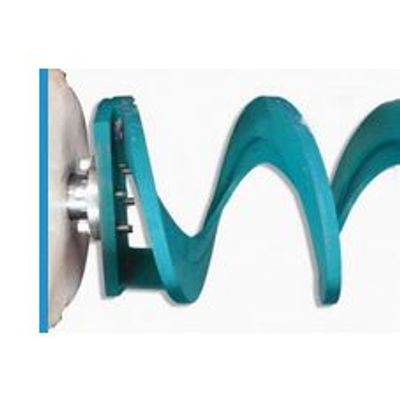

Shaftless Screw Spirals

ML-Spirals - Shaftless Spirals

The heart of any conveying system is the shaftless spiral. Without a properly designed and manufactured spiral, the remainder of the fabricated pieces can be compromised. ML offers the strongest and most robust alloy steel spirals manufactured from high tensile alloy steels, cold formed in a multitude of close tolerance diameters and pitches, up to 762 mm (30 inch) in diameter, and greater, and in a variety of bar sizes as large as 120 x 30 mm (4.8 inches x 1.2 inches).

ML-Spirals - Single Shaftless Spirals

Spirals are usually manufactured in right hand configuration, but can be made left handed. Spirals may be utilized in pushing, pulling or reversing manner. Spirals can be made with or without an insert (second spiral) depending on the design application.

ML-Spirals - Double Shaftless Spirals

Spirals are usually manufactured in right hand configuration, but can be made left handed. Spirals may be utilized in pushing, pulling or reversing manner. Spirals can be made with or without an insert (second spiral) depending on the design application.

Transport & Handling

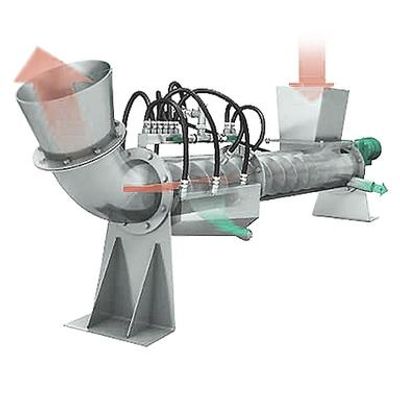

ML Spirals - Screw Compactor

An excellent complement to the screw conveyor. It dewaters and compresses the screening effectively. Depending on the material, volume can be reduced up to 75%. Many installations at municipal water and wastewater treatment plants and industry which are in operation confirm its reliability. A screw conveyor with a dewatering unit in combination with different types of screens gives optimal handling of the screening. Does not affect the capacity when it is combined with the ML screw conveyor.

ML Spirals - Screw Conveyor

Ever since the company started, ML has had shaftless conveyors in their portfolio of products. This means that ML has extensive experience with almost any application and that the conveyors always are tailored and designed for the application they shall work in. The shaftless conveyors are accepted as the leading method for transporting solid materials such as screening, sand, mud, etc. The conveyor is a closed unit, which also makes it safe and quiet in a clean environment.

ML-Spirals - Conveyor Screen

A compact and economic screen for the separation, dewatering and transport of screenings. Specifically designed for the flow of the plant, separation requirements, separation requirements and outlet height. Also, for ease of maintenance and cleaning, U-troughs with removable covers are included.

ML-Spirals - Wash Press

A combined washing and pressure washer and presses for example screenings from a fine screen or a sieve. Manufactured in three standard sizes for different capacity needs. Screening from a fine screen or a sieve, is fed into the unit with a conveyor or directly from the screen. The biological materials are decomposed by jets of liquid and returned back to the system through a perforated metal which is automatically rinsed. The material remains washed further with water and compressed in a press zone before being discharged through at the end of the trough. In the segment for handling of screenings, sand and sludge, we also manufacture equipment for combined washing and pressing of screenings.