MOGAS Industries, Inc. products

Mogas - Customizable Isolation Valves

The C-Series valve is the best choice in large bore isolation applications. MOGAS engineers have successfully designed the C-Series valve line which isolates under the extreme conditions – high temperature up to 1652°F (900°C), high pressures up to 43,000 psig (2965 bar g), media build-up, cycling with solids in the line and erosive attack of materials and coatings. With more than 40 years of engineering expertise, each C-Series valve is designed specifically for the application. Each ball and seat subassembly is mate-lapped by hand and put through a rigorous testing procedure to ensure its integrity. The C-Series valve is available in full or reduced bore, ½ inch to 42 inches and in a wide variety of end connections.

ISOLATOR - Metal Seated Severe Service Ball Valves

Metal-seated severe service ball valves for low pressure applications. Solid rendition of ISOLATOR 2.0 valve. ASME 150 / 300 / 600 Standard Class: Designed for absolute isolation in low pressures and temperatures. ISOLATOR 2.0 is a metal-seated, bi-directional floating ball valve for absolute isolation in specific mining, refining, chemical/petrochemical, power generation and pulp & paper applications. This ASME 150-600 Class valve withstands temperatures to 850° F, and its durable materials of construction and proven coatings reflect its lineage of a longer life cycle over time. Available in sizes 1 to 4 inch and in materials of construction that will suit your application.

Mogas - General Service Ball Valve

The G-Series valve is a general service, uni-directional ASME 600 Class full-bore valve for drain and vent applications with clean, low-pressure steam, gas or liquid. The floating ball design with metal/graphite laminated seats lower torque and actuator requirements.

Mogas - Power Operated Relief Valves

Power operated relief valves for boiler or superheater headers. ASME 1500 / 2500 / 4500 Class: Prevents Excessive Pressure Build-up. The MOGAS PORV, a pneumatic actuated pressure relieving valve, prevents excessive system pressure accumulation. The set pressure of the PORV is lower than that of the spring-loaded safety valve to prevent or reduce the number of lifts of the safety valve, thus extending their life. The PORV is available either non-stamped or with the “V” stamp. The “V” stamped PORV has been flow certified by the National Board of Boiler and Pressure Vessel Inspectors.

Mogas - Vent and Drain Valves

Drain and vent valves for power applications. ASME 600, 900 & 1500 Limited Class: Optimized for Power.

Mogas - Isolation Valves

The SC-3PC has a three-piece body assembly with two proprietary body seals that allow the valve body to be easily removed while the end connections remain in line. The design also allows the valve body to be tested after repair, prior to insertion back in-line. The SC-3PC is used in power plants for isolation of high pressure / high temperature applications.

Mogas - Custom Engineered Valve

Application-specific, custom-engineered solutions for severe service applications. Custom requests are part of our legacy. MOGAS has been in the business since 1973, engineering and fabricating that one exclusive valve that is a non-standard crucial component for your operating system. Unique bore sizes, different end connections and special trim materials are accomplished through our engineered products group.

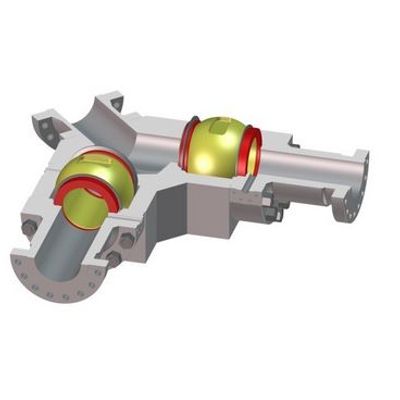

Mogas - Reliable Switching Valve

Reliable switching valve for delayed coker services. ASME 600 – 900 Class: Reliable Switching. MOGAS’ strength is recognized in the harsh environments where reliability, durability and safety are the foundation of successful plant processes. The DV-4 switch valve features many advantages over existing ball or plug valves on the market today. Backed by innovative R&D, world renowned after sales service and a reputation for quality, the DV-4 represents product advancements in delayed coking switching operations.

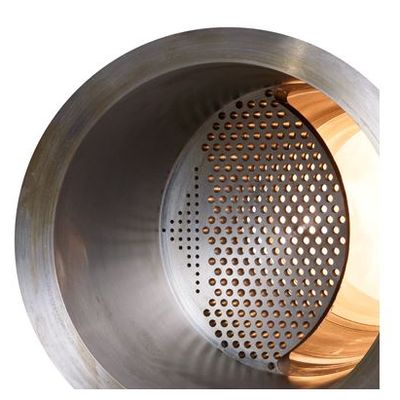

FlexStream - Control Valve

The internal control elements (or trim) use flow paths of various configurations to control flow and pressure drop. This compact trim configuration, located downstream of the seat, consists of a diffusion element and a control element.