Mojonnier products

Mojonnier - Deaeration Systems for Beverages

Deaeration of water is essential to producing quality beverages. It eliminates foam at filler discharge, makes for uniform and efficient carbonation, produces better taste and a longer product shelf life, and stops can corrosion and leakage.

Mojonnier - Carbo Cooler Systems

Since its invention in 1940, the Mojonnier Carbo-Coolers has set the carbonation standard in the beverage processing industry, offering unmatched precision and control in processing cold temperature beverages such as soft drinks, beer, wine, juice, and sports drinks. Mojonnier has continuously upgraded and improved its Carbo-Cooler systems, including the Flo-Blend upgrade.

Mojonnier - Precise Carbo Mix System

The Carbo-Mix system provides simple, precise mix processing technology, generally for applications where little or no cooling is required. An external chiller can be added if cooling is needed. The desired level of carbonation is achieved through an efficient CO2 injection system and pressure-surface dispersion system.

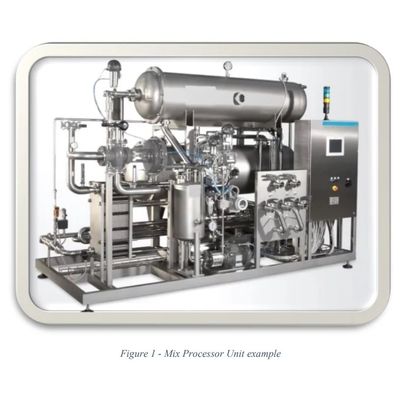

Mojonnier - Meter-based Mix Processor System

Meter-based mix processors are designed to produce carbonated beverages metering syrup, deaerated water, and CO2. The mixed product is cooled by a plate heat exchanger with glycol. The finished mix product can also bypass the blender portion of the mixing processor and be chilled and carbonated. Instruments, automatic valves, and controls with electronic processors adjust the parameters according to with the selected recipe. The mixed product is delivered to a filler via a transfer pump that is tuned with the filler. Includes remote technical support functionality.

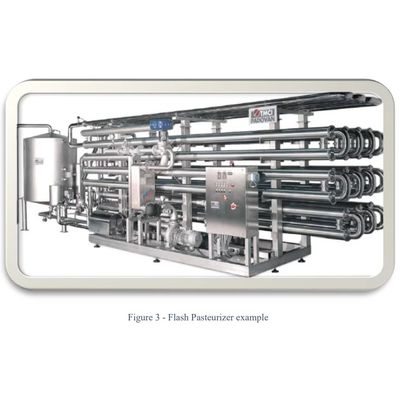

Mojonnier - Flash Pasteurizer Units

Flash pasteurizer units are designed to eliminate microorganisms and enzymes to preserve product characteristics. Units have: High thermal exchange coefficient. Low fouling factor, Easy to clean and maintain. Controls including remote technical support functionality.

Mojonnier - Syrup Room

Complete customizable syrup room solutions to meet product and ingredient mixing needs. Available sub-systems and components include: Batch and/or continuous sugar dissolvers, Sugar syrup filtration, Flash Pasteurizers, Deaeration units and homogenizers, Tanks & piping, Controls including remote technical support functionality.

Mojonnier - Tunnel Pasteurizer Units

The tunnel units are designed to ensure suitable thermal treatment for products of various sizes and package types. Monoblock structure design for small systems and modular structure design for larger systems. Tunnels can be used to pasteurize beer, wine, juices, and lightly carbonated beverages. The system structures contain the process basins and distributing piping, made of stainless steel. The system is available in a single deck or multi-deck. Registration Valves, heat exchangers, circulating pumps, and motors are installed on the exterior of the tunnel to make maintenance of the system easier. Controls include remote technical support

Mojonnier - Sugar Dissolver System

A sugar dissolver system’s main function is a comprehensive solution to empty big bags of sugar and then dissolve, filter, and cool to produce a sugar syrup.