- Home

- Companies

- Molinari S.r.l.

- Products

Molinari S.r.l. products

Machines

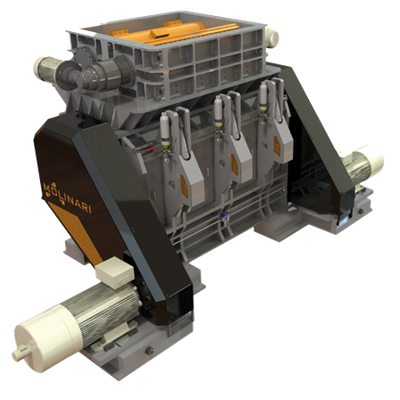

Molinari - Model TPmSeries - Single-Shaft Shredder

The single-shaft shredder of TPmSeries is a perfect machine in the grinding sector. The trapezoidal blades and the speed of rotation guarantee an optimal performance in terms of energy consumption, production and maintenance. The structure of the machine is made by very thick plates, in order to guarantee long lasting, robustness and reliability.

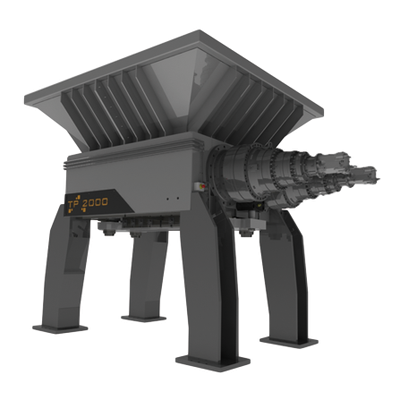

Molinari - Model TP Series - Primary Shredders Machines for PFU

The machines of TP Series are perfect for the volume reduction of ELTs and the production of alternative fuels. The machines of TP Series are the first that make a recovery of used tyres. They can treat either car and truck tires up to 120 cm diameter, and some types of industrial and agricultural tires. Low-speed rotation is the winning feature of this shredders.

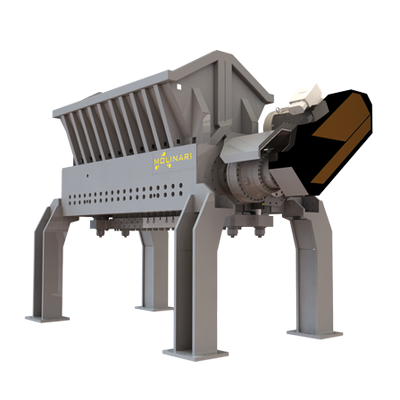

Molinari - Single-Shaft Secondary Shredder Machine for RDF

The Molinari single-shaft shredder is an innovative machine in the field of grinding technology. It provides greater productivity than traditional fine shredders with presser, and may reduce energy consumption by up to 30%. Unlike the other machines on the market, the Molinari single-shaft shredder does not need a presser to push the material against the rotor, thanks to the patented `hollow rotor`. In fact, it is able to `grab` the material without the aid of other devices, with the advantage of working in a continuous way and with a constant energy consumption.

Molinari - Model TG Series - Granulators Machine

The TG granulator was born as an evolution of the tp series primary shredder. The main features of this machine are its robustness and rigidity, which result in a better rubber-cutting performance. What guided the design of the granulator was the desire to pursue the economic sustainability of the company that will use it, as far as this concept can be applied to such a machine. For this reason, we decided to create a machine capable of reusing the wearing parts that are disassembled from the primary shredders. This factor is very interesting both from an economic point of view in terms of savings on consumables, and from the point of view of environmental protection for the processing of raw materials. The negative rake of the blades combined with the peripheral speed of the rotor make it possible to separate the wire from the rubber.

Molinari - Model Helyos FE - Wire Cleaner Machine

Helyos FE is a cleaner for steel coming from end of life tires. its compact design allows to implement in already existing plants. Helyos fe is a vertical-axis machine. the heart of it consists of two discs with opposing planes where the lades are radially installed. The material is loaded from above through an opening on the stator disc. The radial arrangement of the blades and the rotation speed of the rotor, make the material loaded between the two discs come out from the sides, passing through the blades that remove, by rubbing, the rubber residues from steel wires. The output is a mixture of rubber granules, textile and clean steel.an effective magnetic-system allows to separate the steel part from other materials. if necessary, the same machine can be used also as a granulator for shreds.