- Home

- Companies

- Mott Corporation

- Products

Mott Corporation products

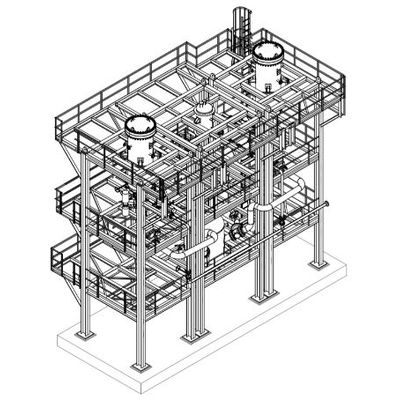

Process Filters, Skids and Elements

Mott - Turnkey Filter Skids

Mott Corporation supplies fully integrated filter skid designs for all major process filtration technologies, including advanced filtration skids for hydrogen production. Through our graded approach to design, a wide partner network, and excellent project management, we deliver complete filtration skids in months, not years. Our filtration skids are designed with modular concepts, allowing us to efficiently integrate customer-specific preferences on piping, valves, instrumentation, controls and programming, and other supporting equipment. By choosing Mott for your complete filtration project, including design and implementation of filtration skids, you reduce your risk and time investment. Our expertise ensures that your filtration system is optimized for performance, reliability, and compliance with industry standards.

Mott - Sintered Alloy Filter Elements

Mott manufactures porous metal filter elements in a broad range of materials, sizes, and fittings, making them easily specified with the characteristics and configurations customers require for their specific filtration needs. We can incorporate custom features or create completely original porous metal filter element designs for specialized needs, ensuring that each solution perfectly matches the application it’s intended for. Mott’s porous metal filter elements are also available in a variety of alloys, each offering unique benefits and suitability for different application purposes, from chemical processing to gas filtration. Our porous metal filter elements are a popular choice for many industrial filtration applications due to their exceptional heat, corrosion, and physical wear resistance, providing reliable and effective filtration under the most demanding conditions.

Ultra High Purity Products

Mott GasShield - Point of Use Filters

For maximum gas filtration efficiency, reliability, and industry-leading flow consistency, GasShield® point of use filters are ideal for Ultra High Purity (UHP) gas delivery applications. These point of use filters are available in a variety of materials and are compatible with most high purity electronics grade process gases, ensuring optimal performance.

Water Reclamation System

Mott - Nutrient Concentration & Water Reclamation Systems

Combining our exclusive solutions, we can deploy totally integrated solutions for onsite nutrient concentration and water reclamation. The Nutrient Concentration & Water Reclamation (NCWR)™ System can process various raw wastewaters, manures, and digestates, and separate the flow into clean, reusable water–ideal for facility re-use or discharge–and concentrated liquid products. These concentrates are often valuable co-products such as fertilizers and animal feeds. With most materials, we can recover more than 70% of the total volume as clean water while concentrating the nutrients significantly.

Industrial Filter Cartridges

Mott - Cleanable Filter Cartridges

Mott is your trusted source for a diverse selection of cleanable filter cartridges designed to meet the specific requirements of various industrial applications.

Filter Assemblies and Porous Components

Mott Corporation - Porous Metal Cups

Mott’s porous metal cup designs can be tailored for an extensive range of applications and specifications. These porous cups can be integrated with both metallic and non-metallic hardware options, offering a comprehensive assembly solution. We can adjust numerous parameters, including length, diameter, thickness, alloys, and media grades, ensuring our porous cups address diverse filtration, flow, and chemical compatibility requirements for your product or process. With a commitment to innovation and precision, Mott ensures that each porous cup is crafted to deliver optimal performance and longevity.

Frit Assemblies and Lab Filters

Mott Corporation - Porous Chromatography Column Frits

Mott’s porous chromatography column frits play a pivotal role in High-Performance Liquid Chromatography (HPLC) columns by effectively retaining the packing media and ensuring a consistent sample flow with minimal hold-up volume. These specialized frits are engineered to withstand not only high pressures but also the most corrosive chemicals, making them ideal for demanding chromatographic applications. Additionally, Mott offers bio-inert column frit options, further expanding the versatility of these crucial components for a wide range of chromatography needs.

Industrial Gas Flow Restrictors

Mott Corporation - Gas Flow Restrictors

Porous metal flow restrictors are essential in applications that demand anti-clogging capabilities or laminar flow. The unique design, featuring thousands of flow paths through the porous metal, effectively prevents the restrictor from clogging if a large particle enters the gas stream. This innovative thousand-pore structure of porous metal flow restrictors ensures laminar flow in even the most intense conditions and eliminates turbulent flow on the outlet, making them highly reliable for critical applications. Moreover, these restrictors are available in a wide variety of alloys and hardware configurations to suit any specific process requirements. Their versatility and efficiency make porous metal flow restrictors an ideal choice for industries seeking precise flow control and durability in their systems.

Industrial Sparger Systems

Mott Corporation - In-Tank Spargers

Mott in-tank spargers increase gas absorption by as much as 300% over traditional sparging technologies, resulting in faster throughput and less gas usage. These in-tank spargers can be used with virtually any gas or liquid to improve gas absorption in a variety of processes, making them highly versatile for industrial applications. Because porous metal provides thousands of flow paths, gas exits through the in-tank spargers in very small bubbles, resulting in far better absorption than traditional sparging technology. This efficiency is crucial in processes requiring precise control over gas dissolution rates and uniform gas distribution within the tank. Whether you’re looking for a single sparger or multiple sparger assemblies for a large tank, we’re here to fulfill your needs, ensuring optimal performance and efficiency in your operations.