MSE Filterpressen GmbH products

Filter Presses

MSE Filterpressen - ATEX Filter Press

On the one hand, ATEX filter presses differ only slightly from conventional filter presses. The basic architecture, the working principle and process engineering are identical. However, the difference is in their structural protection measures. Here, the ATEX filter press, with its specific requirements, complies with the ATEX directives. As a result, these types of filter presses are designed for a high level of safety and explosion protection.

MSE Filterpressen - Semi-Mobile Filter Press Plant

Especially in rapidly changing markets, it is all the more important to rely on a partner with many years of market and expert knowledge. With semi-mobile container plants – similar to mobile filter presses – we support you in defying the rapid changes on the market in order not to jeopardise your core business. Semi-mobile filter presses can be used flexibly and are also quickly ready for operation. Especially for temporary projects, the required container plant can be made available in an uncomplicated manner. Wherever construction progress requires it. Furthermore, the semi-mobile filter press is fully equipped and immediately ready for operation after connecting to sludge, water and power supply. MSE Filterpressen plans and manufactures the plants for individual customer requirements. In this way, the best possible result can be achieved for every task.

MSE Filterpressen - Hot Filter Press

The hot filter press combines the standard process steps of a membrane filter press, (filtration, filter cake washing and squeezing), with the additional function of a thermal filter cake drying (TCD). As a result, all process steps are carried out in one plant, the hot filter press. Dewatering and drying of the resulting filter cake is thus done without a downstream drying process. Cost-intensive and time-consuming vacuum contact drying is therefore no longer necessary.

MSE Filterpressen - Mobile Filter Press Plant

Sludge dewatering in municipal or industrial waste water treatment is classified as complex. Not only the composition of the sludge, but also the economic and technical boundary conditions of the plant vary greatly. The optimal solution can only be reached by analysing the overall situation. Minimising dewatering costs while simultaneously reducing residue quantities are also clearly defined objectives for users. Accordingly, a stationary filter plant can only be used with a low degree of utilisation. Cost-intensive investments are therefore often offset by moderate capacity utilisation.

MSE Filterpressen - Rubberized Filter Press

On the one hand, rubberised filter presses differ only slightly from conventional filter presses. The basic architecture, the filtration principle and process technology are identical. However, they differ in their surface properties. Based on the decisive properties of the flexible material, the rubberised filter press is mainly used for the filtration of particularly aggressive suspensions and environments. The aggressive suspensions include, for example, solvents or acids. In this context, the conventional painting of the steel parts is no longer sufficient.

MSE Filterpressen - Chamber Filter Press

In addition to its simple and inexpensive design, the chamber filter press is also a powerful and reliable filter press. The type of suspension to be filtered (e.g. mining, chemical or pharmaceutical industry) is irrelevant. In order to meet the different requirements of industry and municipalities, MSE chamber filter presses are designed for this in modular design. The solid and heavy-duty steel filter press frame, which consists of the following main components, forms the basis: Feeding stands with filtrate outlet (head piece), hydraulic stands with locking cylinder (pressure piece), cross beam and side rails on which the individual filter plates are arranged accordingly including filter cloths. The plate pack also consists of uniform chamber plates with a cut-out of 15-50 mm for holding the puncture-proof filter cake. Polypropylene (PP) is used as the chamber plate material in the standard version.

MSE Filterpressen - Membrane Filter Press

Due to its excellent filtration results, the membrane filter press has proven itself in a number of applications, e.g. in mining, chemical or pharmaceutical industries. In order to meet the different requirements of industry and municipalities, MSE membrane filter presses are designed in modular design analogous to chamber filter presses. The solid and heavy-duty steel filter press frame, which consists of the following main components, forms the basis: Feeding stands with filtrate outlet (head piece), hydraulic stands with locking cylinder (pressure piece), cross beam and side rails on which the individual membrane filter plates are arranged including filter cloths.

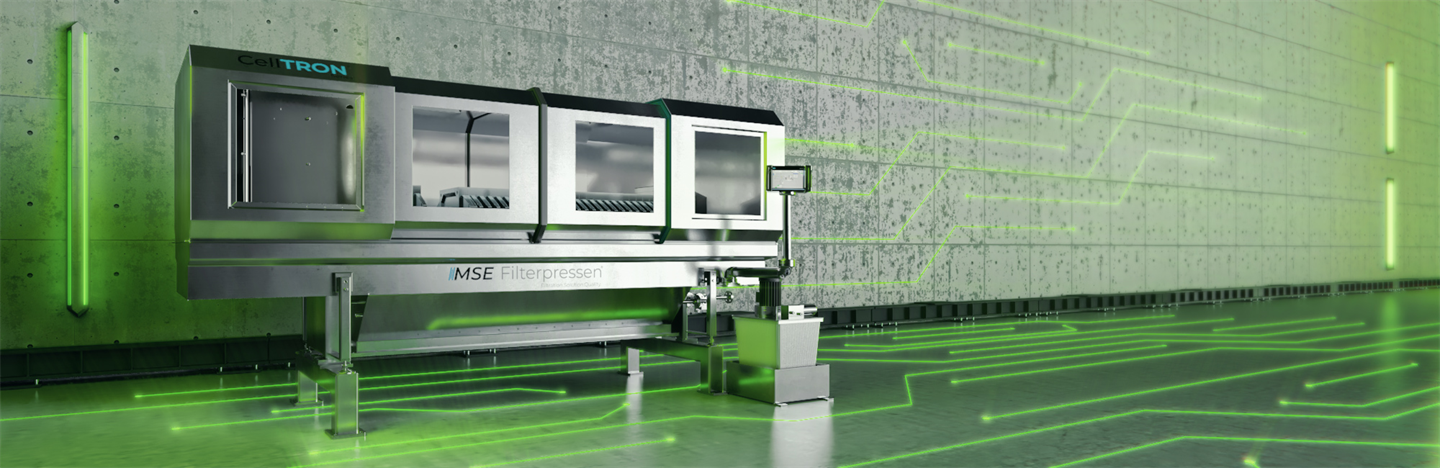

MSE Filterpressen - Fully Automatic Filter Press

At first, fully automatic filter presses differ significantly from conventional filter presses. The basic architecture, the working principle and process technology are identical. Fully automatic filter presses are specifically designed for applications in which a continuous operation and fast cycle times are essential and therefore crucial. MSE fully automatic filter presses provide a high degree of automation while providing uninterrupted operation at the same time. The option of the simultaneous filter plate opening system, for example, helps to realise a particularly fast cake release reducing the cycle time to a minimum. The result is a high-speed filter press that allows increased production per unit area of filter. For this reason, these machines are used in applications with highly filterable products where high filtration speeds are required. These include, e.g. mining concentrates and residues.

MSE Filterpressen - Conveying Systems for Filter Presses

The task of conveyor systems for filter cake discharge is as varied as the products to be filtered. The filter cake discharge not only fulfils the transport task of the accumulating filter cake. It also includes further process steps such as: crushing, cooling, weighing, dosing, compressing, mixing, discharging and much more. Driven conveyor systems such as conveyor belts, conveyor screw systems or trough chain conveyors with hoppers, which are adapted and connected directly under the filter press (installed on a platform), can be used for filter cake transport. The discharged filter cake is thus transported directly to the appropriate storage facilities.

MSE Filterpressen - Stainless Steel Filter Press

On the one hand, stainless steel filter presses differ only slightly from conventional filter presses. The basic architecture, the working principle and process technology are identical. However, the difference is in their structural protection measures. Depending on the application area (chemical, pharmaceutical or food industry), certain guidelines must be adhered to. MSE stainless steel filter presses comply with the high hygiene and purity standards both in design and processing. With the stainless steel filter press, all components in contact with the product (with the exception of the filter plates) are covered with high-quality stainless steel. This also provides optimum protection against corrosion. In special cases, the filter presses can be made entirely of stainless steel or is stainless steel-plated.