MTE Group products

MTE Catalyst Support - Catalyst Bed Support Media

MTE Rest-O-Cat - Inert Ceramic Balls for Catalyst Bed Support

MTE Group offers the Rest-O-Cat® inert ceramic balls, a standard solution in refinery and petrochemical industries for catalyst bed support. These ceramic balls, produced under MTE's meticulous quality assurance system, are engineered to be chemically inert and unaffected by various process atmospheres. They come in multiple sizes to accommodate different needs and are readily available from stock, ensuring quick delivery. High-grade options are available for severe operating conditions. The versatile application of these balls extends to fertilizer, natural gas, and industrial gas production processes. MTE Group's capacity for mass transfer solutions is amplified by its central location in the Netherlands, featuring a technology center and substantial warehouse facilities to support urgent customer requirements around the clock.

MTE Catalyst Support - Catalyst Top Layer Media - Inert Top Layer Media

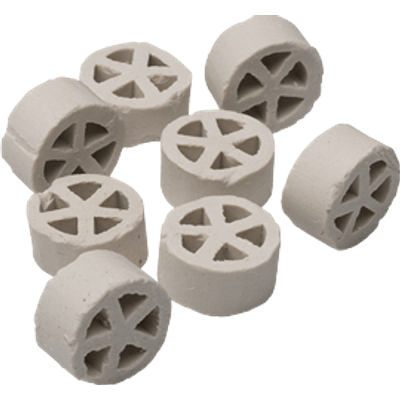

MTE - Inert Ceramic Top Layer Wheels

MTE Catalyst support develops inert top grading materials designed to optimize the performance of catalytic reactors. These materials serve as an effective replacement for traditional inert ceramic and alumina balls. The innovative design features increased void fractions and customizable shapes to enhance distribution properties, reducing particulate deposition and top bed crust formation. The Rest-O inert top gradings product range is produced with a stringent quality control system to ensure suitability across various operational specifications. Technical advancements in these media allow for better resistance to solid deposits such as rust, gum, and coke. For specific requirements, MTE offers comprehensive design recommendations, grading production from regenerated catalysts, and tailored customization in shape and material. An array of associated products, including porous and active top layer media, complement the range. Leveraging their expertise, MTE aims to provide optimal solutions for mass transfer challenges in industrial applications.

MTE Catalyst Support - Ceramic Packing

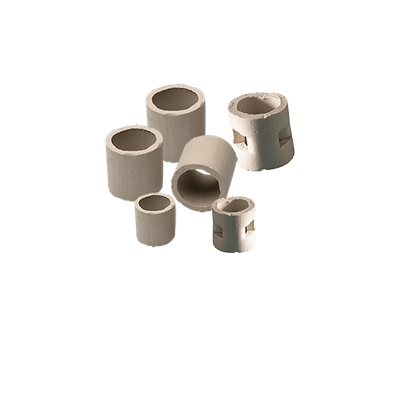

MTE - Ceramic Rings for Mass Transfer Applications

Ceramic rings, essential in various mass transfer processes, exhibit notable acid resistance and are available in multiple sizes and materials to cater to diverse industrial applications. Their effectiveness is leveraged in processes needing optimal contact between vapor and liquid phases while minimizing liquid holdup in columns. Smaller sizes up to 8 mm serve predominantly as catalyst support media, whereas intermediate sizes between 10 to 12 mm find usage in water filtration systems. Larger rings, ranging from 25 to 50 mm, are effective in acid scrubbers and strippers with low gas flows, and rings of 100 to 200 mm, featuring single walls or cross partitions, enhance mechanical strength for use in sulfuric acid drying towers. Ceramic pall rings, characterized by side openings, improve separation efficiency and mass transfer while reducing pressure loss. The ability to supply different ring designs quickly across Western Europe is supported by MTE Group's significant stock volume and distribution network.

MTE Process Technology - Column Packing - Metal Random Packing

Metal C-ring for Gas and Chemical Applications

The Metal C-ring is a crucial component in gas hydration, glycol absorbing, biogas, and chemical washing applications. It features a cylindrical axis oriented vertically, promoting efficient gas flow with minimal obstruction. The unique configuration of the Metal C-ring results in a low pressure drop and improved flow rates, especially in smaller column diameters and fan sizes of new systems. This component boasts high mechanical strength, making it suitable for deep packed beds which enhance hydraulic capacity. Its design reduces fouling due to its horizontal and vertical shape, boosting the efficiency of packed beds. Manufactured by MTE in different sizes, thicknesses, and materials, Metal C-rings are shipped across Western Europe within 24 hours when in stock. MTE specializes in mass transfer solutions, with comprehensive engineering and production capabilities based in the Netherlands, providing global service through an extensive distribution network.