The ceramic rings are broadly used in many heat transfer applications and have excellent acid resistance. We provide the ceramic rings in a variety of sizes, designs and materials.

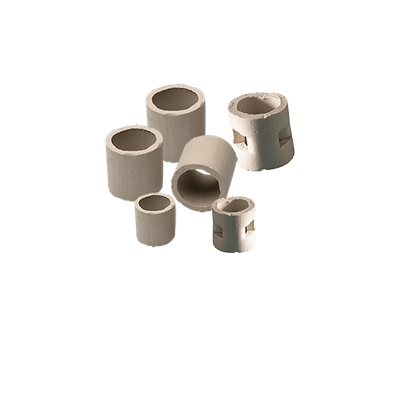

Ceramic raschig rings

The ceramic raschig ring is a simple cylindrical shaped tube with an aspect ratio of 1:1. The aspect ratio is defined as the ratio between the height and the diameter of the raschig ring. Promoting contact between vapor and liquid phases, while minimizing liquid holdup of the column. Raschig rings are long lasting and cost effective, therefore still used today in many mass transfer applications, preferentially however, for refilling existing columns.

The ceramic rings are available in a wide range of sizes.

The small sizes up to 8 mm are mainly used as catalyst support media. Ceramic rings of 10 to 12 mm are also widely used in water filtration systems. Larger rings from 25 to 50 mm are normally used in acid scrubbers and mainly strippers with low gas flows. These rings can also be produced in high alumina material for additional temperature or chemical resistance.

Larger rings from 100 to 200 mm are often produced with a single wall or cross for mechanical strength. These cross partition rings are used as support device ceramic random packing in i.e. sulfuric acid drying towers. The rings are stacked on ceramic beams to create a strong, corrosive resistant and removable grid.

Ceramic pall rings

Ceramic pall rings are executed with side openings which improves the separation efficiency and thus facilitate a more effective mass transfer. The pressure loss is further reduced due to moderate gas deflection. The capacity characteristics of the ceramic pall rings are more constant in comparison with the cylindrical rings, even over a broader load range.