newtec Umwelttechnik GmbH products

Physical Water Ionization (PWI) System

Physical Water Ionization (PWI) uses dynamic adjustable electromagnetic fields acting on calcium crystals in flowing media against calcification, completely without chemicals. PWI may also reduce the surface tension of liquids.

Newtec - In-Situ Disinfection System

The in-situ disinfection system is a part of the electrolytic disinfection technology. The main point of this technology is the cell of electrolyse, in which flow special coated, patented eco-dis-electrodes of water that is necessary to disinfect.

Newtec - NaOCI Electrolyser Equipment for On-Site Production

Product: low concentrated NaOCl with 0.8% part of chlorine. The NaOCI electrolyser of the nt-series is modern equipment for the local production of NaOCI solution for different disinfecting applications. The basic principle of it`s operation is the following one: If a specific voltage is applied in the electrolytic tube without membrane which contains a 3% NaCI solution, a series of electrolytic reactions takes place. As a consequence of this reactions there will be generated a product solution with 0.8% NaOCI.

Legionella Prevention

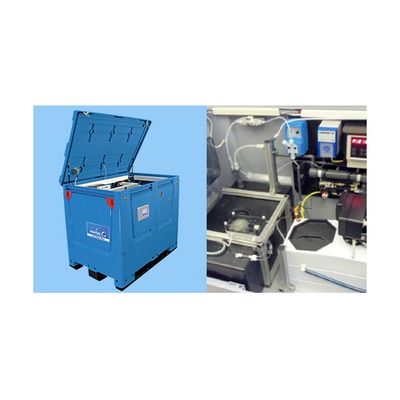

nt-BlueBox - Complete Electrolysis and Adjusted Dosage

In our nt-BlueBox the complete electrolysis and adjusted dosage is pre-installed in a very compact form. The concentration of the disinfectants in the tap water is monitored by a measuring bypass. The nt-BlueBox product range has different production capacities of sodium hypochlorite, starting from 3g/h, 5g/h, 12g/h, 30g/h, 60g/h, 90g/h, 150g/h, 200g/h und 300g/h.

Electrolysis Disinfection

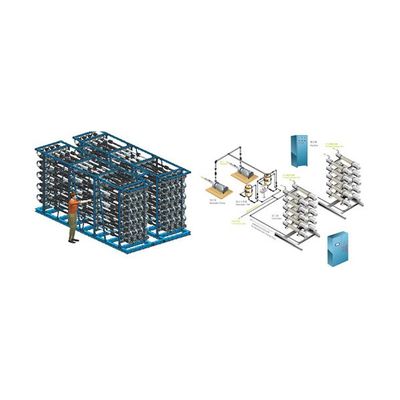

Salt Water Electrolysis

A plant for salt water electrolysis nt-CLE consists of a water softener, a brine tank, electrolysis cells with rectifier, a product tank, dosing pumps and controller. Capacity of the nt-CLE for salt water electrolysis: 0.5 to 40kg/h per electrolysis unit. Concentration of the on-site produced NaClO solution: 0.5% to 0.8% active NaClO. Consumption (per kg active Cl2): up to 3.5kg NaCl, 4kWh.

Seawater Electrolysis Plants

The seawater electrolysis plants nt-CLE-S consist of submersible pumps, self-cleaning filters, an electrolysis unit with rectifier, a product tank, dosing pumps and controls as required. Capacity of the nt-CLE-S series for seawater: 0.5 to 120kg / h per electrolysis unit Concentration of the on-site produced NaClO solution: up to 0.25% active NaClO Consumption (per kg active Cl2): up to 4.0 kWh, no salt.

Chemical-Free Water Treatment

Ultrafiltration (UF) and Reverse Osmosis (RO) System

Modern membrane filtration is used for the purification of drinking and process water. The UF more and more replaces the classical sand filtration in waterworks. Depending on the application, the UF serves as a preliminary stage for the RO. Combined with electrolysis disinfection UF membrane cleaning is automated and aggressive cleaning chemicals are avoided.