- Home

- Companies

- NLB Corporation

- Products

NLB Corporation products

Pumps & Units - HP Diesel Water Jetting Systems

NLB - High-Pressure Water Jetting Diesel System

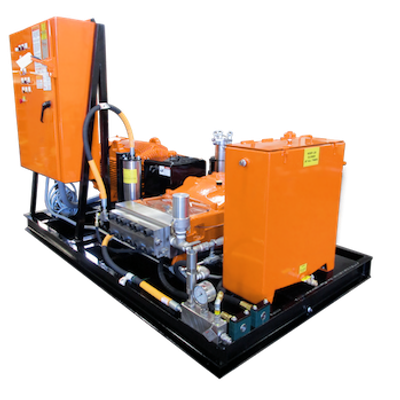

This innovative line of high pressure water jetting units are designed around the model 125 convertible pump. This pump, with its quick-change, in-line fluid end design, has fewer parts for increased operating efficiency and simpler maintenance. And, it requires only a simple conversion kit to operate at pressures between 6,000 and 40,000 psi (415 and 2,800 bar).

NLB - High-Pressure Water Jetting Diesel System

The NLB 225 Series water blasting units are among the most widely used in the field today, outperforming other models regardless of manufacturer. With horsepower options ranging from 200 to 350 hp (149-261 kW) and pressures from 4,000 to 40,000 psi (275-2,800 bar), the 225 Series delivers exceptional performance across a wide variety of applications. Whether you’re stripping paint, cleaning tubes, or blasting the inside of a tank, the 225 Series combines flexibility, power, and reliability to get the job done efficiently.

NLB - High-Pressure Water Jetting Diesel System

The 325 Series water blasting units are quintuplex versions of the 225 Series. What that means is that opposed to three plungers, these have five, allowing them to run at higher horsepower and produce higher flows. Because these units use the exact same fluid end components as the 225 Series, they are a perfect next step when higher horsepower is needed. Models are available ranging in horsepower from 365 to 450 hp (272-336 kW) and with pressure from 8,000 to 40,000 psi (550-2,800 bar).

NLB - High-Pressure Water Jetting Diesel System

What does one do with a pump that has 600 hp (447 kW) and pressures to 40,000 psi? Why, whatever one wants. The 605 Series diesel-powered units are the 800 pound gorillas of the water blasting world. With power and flexibility to spare, if your application can’t be tackled by one of these units, it can’t be tackled at all. Models are available ranging in horsepower from 475 to 600 hp (354-447 kW) and with pressure from 4,000 to 40,000 psi (275-2,800 bar).

NLB - High-Pressure Water Jetting Diesel System

The 1005 Series diesel-powered units from NLB set a new standard for high horsepower units. With power and flexibility to spare, if your application can’t be tackled by one of these units, it can’t be tackled at all. Models are available ranging in horsepower from 750 to 1000 hp (560-746 kW) and with pressure from 4,000 to 20,000 psi (275-1,400 bar).

Electric Units - HP Electric Water Jetting Units - Convertible Units

NLB - Electric Water Jetting Units

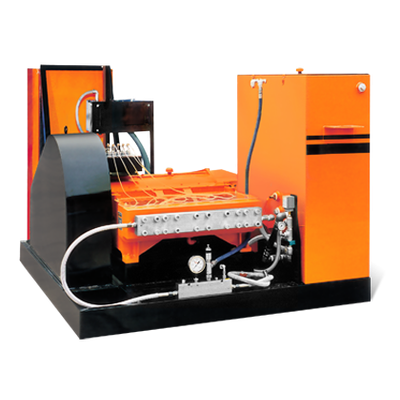

The NLB 125 Series electric water jetting units are built for demanding applications like carrier and container cleaning, offering exceptional durability and efficiency. At their core is a rugged, slow-running triplex plunger pump designed to minimize wear, extend component life, and reduce maintenance costs. Built around the reliable Model 125 convertible pump, these units feature an innovative quick-change, in-line fluid end with fewer parts, enhancing efficiency and simplifying maintenance. With a straightforward conversion kit, operators can easily adjust pressures from 6,000 to 40,000 psi (415 to 2,800 bar) and flow rates up to 32.5 gpm (123 lpm), making them highly versatile. Their ability to tackle tough cleaning tasks while maximizing uptime and performance makes the 125 Series the ideal choice for industries requiring powerful, high-pressure water jetting solutions.

NLB - Electric High Pressure Water Jetting Systems

NLB’s newest water jetting unit is turning heads – and for good reason. The new NLB 175 Series brings all the features that users want at a price that is less than one might think for NLB quality. Careful engine pairing and engineering help to generate more of what users need (namely pressure and flow), utilizing a smaller, higher output power frame. The result is a jetting unit with the performance needed in a smaller, lighter package. The 175 Series isn’t some stripped-down, quality-compromised effort on anyone’s part. It’s all the NLB quality and more that carries the NLB nameplate. The units are built using the same rugged, reliable designs that have been field-proven for over 50 years. The trailer-mounted unit comes standard with features like four-wheel electronic brakes, a full D.O.T. lighting package, and heavy-duty axles.

NLB - Electric High Pressure Water Jetting Systems

The 225 Series Electric Units are part of the 225 Series family, the most widely used water blasting model in the field today, outpacing nearly every other unit, regardless of manufacturer. The 225 Series Electric Units are just as versatile, offering horsepower ranging from 150 to 250 hp (112-186 kW) and operating at pressures from 4,000 to 40,000 psi (275-2,800 bar), delivering outstanding performance across various applications. Whether you need to deburr parts, clean tubes, or clean the inside of a tank, the NLB 225 Series provides the power and flexibility to tackle any job.

NLB - Electric High Pressure Water Jetting System

The 325 Series water blasting units are quintuplex versions of the 225 Series. What that means is that as opposed to three plungers, these have five, allowing them to run at higher horsepower and produce higher flows. Because these units use the exact same fluid end components as the 225 Series, they are a perfect next step when higher horsepower is needed. Models are available ranging in horsepower from 250 to 350 hp (186-260 kW) and with pressure from 8,000 to 40,000 psi (550-2,800 bar).

NLB - Electric High Pressure Water Jetting System

The NLB 605 Series electric units are the industry standard for high horsepower water jetting, designed to handle the most demanding applications while offering low emissions and reduced noise. Perfect for in-plant tasks like powdered metal manufacturing and reactor cleaning, these units combine power, flexibility, and reliability. Built around the 605 convertible pump, the system features a quick-change, in-line fluid end design that reduces the number of parts, increasing operating efficiency and simplifying maintenance. The pump operates at pressures ranging from 4,000 to 40,000 psi (275 to 2,800 bar) with just a simple conversion kit, providing unmatched versatility for various high-pressure tasks.