- Home

- Companies

- NOVA Industries

- Products

NOVA Industries products

Screening & Headworks

NOVA AquaGuard - Self-Cleaning Moving Media Screen

The Aqua Guard® Screen series, developed by Parkson Corporation, provides innovative screening solutions tailored for wastewater treatment processes. It offers variants such as Aqua Guard, Aqua Guard Ultraclean, and Aqua Guard-PF, each utilizing advanced three-dimensional screening technology to ensure effective solid separation and water filtration. The screens come equipped with a self-cleaning mechanism that minimizes manual interventions, thereby reducing downtime and maintenance efforts. Constructed from high-quality, corrosion-resistant materials, these screens display exceptional durability and robustness, making them suitable for varying scales of operations in aggressive environments. Engineered to be energy-efficient, they contribute to reduced operational costs while processing substantial volumes of wastewater. Their adaptable design allows customization for different facilities, making them versatile for various treatment applications. Successfully integrated in global installations, these systems play a key role in enhancing sustainability efforts in wastewater management.

Aeration

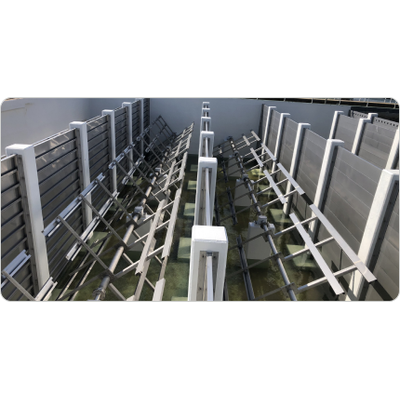

NOVA OTT - Model Standard 2 - Diffusers

The OTT STANDARD 2 tube diffuser is ideal for retrofitting existing wastewater treatment facilities. It features patented engineering, including an integrated air channel for uniform air flow and a membrane mounting ridge for secure, wrinkle-free positioning.OTT diffusers provide highly efficient fine-bubble aeration. STANDARD 2 diffusers are easily installed on rectangular headers with 30, 40, or 45 mm (1.57" or 1.77") diameter outlet openings using double-threaded connectors available in PP-GF, stainless steel, or brass. They can also be installed on round headers with 20 mm (0.79") diameter openings using a saddle-contoured adapter, ensuring secure mounting and resistance to high temperatures and formic acid.Available in stock lengths of 500, 750, and 1000 mm (19.69", 29.53", and 39.37"), STANDARD 2 diffusers can also be custom-fabricated to specific lengths for specialized applications.

Mixing

NOVA MRI - Flocculators / Mixers For Precision Flocculation

The MRI Flocculation System offers an advanced, efficient, and adaptable solution for optimizing the flocculation process in water treatment plants. Its multi-stage approach, combining mechanical and hydraulic mixers, provides precise control over the entire pretreatment process, ensuring effective floc formation and sedimentation. With key features like variable speed mixers, a self-cleaning hydraulic stage, and flexible configuration options, the MRI Flocculation System delivers enhanced performance, energy efficiency, and reduced maintenance requirements. Mix and Match with our Flocculator systems. MRI Flocculation Systems can use vertical turbine, horizontal paddle wheel, or hydraulic flocculation or a combination in the first three stages, allowing for a wide range of G-values. Basin configuration or preference can determine which device is best suited.

Biological

iDEC - Model SBR - Decanting System for Wastewater Treatment

The iDEC SBR Decanting System is designed to enhance the Sequencing Batch Reactor (SBR) process, offering reliable decanting for wastewater treatment facilities. It incorporates advanced technologies that ensure improved effluent discharge quality by maintaining a constant inflow velocity through its collector head, which reduces turbulence and prevents the suction of settled sludge. Built with high-quality stainless steel, the system provides robust and durable service, minimizing maintenance needs and operational costs. Ideal for both municipal and industrial uses, it adapts well to fluctuating influent conditions and integrates easily with SCADA systems for streamlined monitoring and management. Additional features include automated decanting, a non-clogging design, and adjustable decanting height, ensuring optimal flexibility and process control while supporting energy-efficient operations.

Clarification

NOVA MRI - Inclined Plate Settlers for Water Treatment

The MRI Inclined Plate Settler is engineered to enhance sedimentation and solid-liquid separation within water treatment facilities. It utilizes inclined plate technology to improve settling efficiency, resulting in high-quality effluent standards and a compact system design, well-suited to facilities aiming to optimize spatial efficiency. Operationally, it incorporates an influent distribution system, where water flows across inclined plates, allowing for sedimentation via gravity. This arrangement facilitates effective sludge collection and removal while directing clarified effluent discharge. Its design significantly reduces its footprint relative to conventional systems, supporting higher throughput and suitability for large-scale facilities. The simple design and minimal mechanical components result in low energy demands and ease maintenance requirements, favoring long-term system reliability. Its modular configuration allows customization and ease of integration into various projects, making it a versatile choice for diverse treatment needs.