PH Tool products

Calibration Test Blocks

IIW-Type 1 Block

Note: In 2018, PH Tool stopped including the Ø2 (50mm) acrylic plug in this product. Plugs will be available upon special request only, and will add cost. This non-essential feature has long been considered optional per block specifications and is largely obsolete. Used for calibration of shear and longitudinal transducers, and verification of shear wedge exit point and refracted angle. Can also be used for resolution and sensitivity checking. In accordance with: IIW (International Institute of Welding) and ASTM E164, U.S. Customary Block.

Wood Case for IIW-Type Blocks

Fitted wooden case to fit PH Tool`s IIW-Type calibration blocks. Compatible with: IIW-Type 1 Block, IIW-Type 2 Block, ISO 2400 Calibration Block No 1 (K1), BS2704 V1/5 A2 Calibration Block ,PAUT IIW Block, ISO 19675. Note: cases shown in photo may not be applicable for the block(s) you are purchasing; they are shown as examples ONLY. All PH Tool wood cases are custom-made to fit specific blocks and are constructed and priced accordingly.

Reference Standards for NDT

Turbine Blades, Air Foils & Buckets

PH Tool™ routinely machines EDM notches in turbine components including blades, buckets, disks, wheels and more. Customer-supplied items can be notched, but we also are able to wire EDM complex parts from comparable alloys in situations where no supplied part is available.

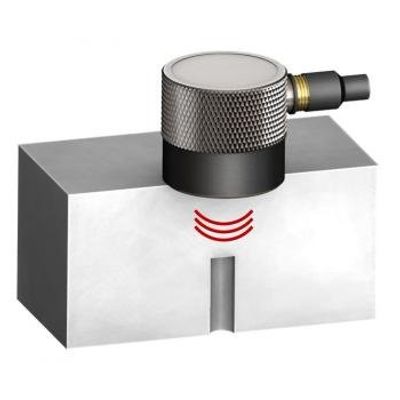

Crack Propagation Notches

Most notches that we machine here at PH Tool™ are used as targets for one of many NDT disciplines such as UT or ET. But application for EDM notches doesn’t end there. We have many customers who use our super-precise slots as “Starter Notches” for crack propagation purposes. Think of these application-specific notches as initiators for the mechanical cycling and fatiguing in order to grow an actual crack. They have also been referred to as, “manufactured stress concentration artifacts." The name says it all. Care is given to engineer the exact size, shape, and location required to achieve the ideal result. EDM electrodes can be shaped to virtually any configuration to guide fatigue crack shape. Contact Technical Sales for more information on notches for Crack Propagation.

Flat Bottom & Other Holes

Flat-Bottom Holes (FBH)

The machining of flat bottom holes constitutes a large part of what we are known for at PH Tool™. These holes appear in many test blocks such as ASTM reference blocks made to E127 and E428, and many other block types as well. In addition, countless application-specific standards employ the use of flat bottom holes at various depths and diameters. They simply make for excellent ultrasonic inspection targets with very predictable and quantifiable dimensions. We take many steps at PH Tool to ensure that you get a drilled flat bottom hole of the highest quality available. We employ both conventional machining (drilling) and nonconventional (EDM) machining in the hole-making process. The determining factors we consider in choosing a method are machinability of the workpiece, accessibility, hole diameter and depth. Most FBHs are drilled in the range of 0.250” (6.25mm) diameter and under.