Picvisa Machine Vision Systems S.L.U products

PICVISA - Plastic Flakes Sorting

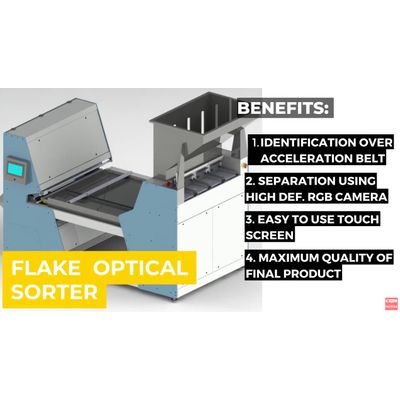

The ECOFLAKE optical classification systems have been designed for demanding classification applications that require low material loss. They are equipped with high-resolution RGB cameras, cutting-edge NIR technology, and an innovative belt feeding system, allowing for exceptional separation ratios and increased stability. Standard equipment: Cutting-edge LED lighting with a high color rendering index CRI90. VPN internet connection. Secure remote access for supervision, adjustment, and maintenance. Programmable automatic cleaning. MATERIALS AND APPLICATIONS PLASTIC Plastic sorting: color sorting of polyethylene. METALS Metal sorting: sorting of copper, brass, and aluminum. PET Purification of PET flakes: removal of impurities and color sorting.

Optical Sorting

PICVISA - Glass Recovery Optical Sorter

The ECOGLASS optical sorter allows the automatic classification and separation of various types of materials, by composition (NIR), colour (VIS) and/or shape (deep learning). ECOGLASS models are designed to work in glass recovery and cleaning processes in different flows. These equipments are designed in a versatile concept of easy adaptation to different processes where the material is crushed and requires separation or cleaning by means of colour and shape criteria. By means of different options it is also possible to detect lead content in glass and ferrous and non-ferrous metals.

PICVISA - Materials Optical Sorter

The ECOPACK optical sorter allows the automatic classification and separation of various types of materials, by composition (NIR), colour (VIS) and/or shape (deep learning). Thanks to the flexibility of the multispectral vision, ECOPACK can be configured to make quick changes in the classification of new materials to be separated that may arise in the inlet treatment flow. The ECOPACK models are designed to work on acceleration belts from 1000 mm to 3000 mm with different separation options (Double Bar or MultiTrack) according to the customer’s needs.

Picvisa - Textiles Optical Sorter

The ECOSORT TEXTIL optical sorter allows you to automatically classify and separate different types of textiles by composition (NIR), color (VIS) and/or shape (deep learning). Thanks to the flexibility of multispectral vision, ECOSORT TEXTIL can be configured to make rapid changes in the classification of the different textile materials that the customer may need. ECOSORT TEXTIL is designed to work on 1000mm belts and can be combined with both side blowing and a robotic arm such as ECOPICK to separate the different textile categories.

ECOCLIP - PICVISA

ECOCLIP The ECOCLIP optical sorting make textile and fashion circularity possible granting proper and accurate clippings automatic sorting in textile recycling centers worldwide. Sorting of textile based on fiber compositions and colors Quality control of pre-sorted fractions Automatic detection and separation of hard points Metal detection Analysis of the entire surface Clipping textile size starting from 25mm 2.5 tons/hourWaste Classification Robotics

PICVISA - Artificial Intelligence (AI) Based Robot

ECOPICK is an artificial intelligence (AI) based robot that recognizes and classifies a wide variety of objects on a conveyor belt, replacing the tasks usually performed by a manual triator. Its waste classification tasks consist of carrying out quality control of materials. But also the automated extraction of recoverable materials contained in the flow of “rejects” conducted to the cabin through a conveyor belt.

Brain- Analysis and Feasibility Waste Recovery Studies Services

PICVISA - Artificial Intelligence-Based Waste Recovery Flow Analyzer

The ECOFLOW flow analyzer is based on artificial intelligence and allows image collection, data processing and data visualization. Analyzes the flow of your plant to obtain valuable information for decision making. The fastest way to convert your waste plant into a 4.0 plant.