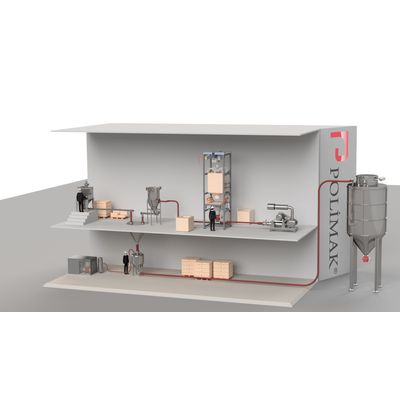

A bulk material handling system is required in any process that necessitates bulk material processing. Bulk material handling systems produced by Polimak are designed to the specific requirements of each industrial application. This ensures the deliverance of state of art solutions for the toughest challenges. Our bulk material handling systems’ fundamental role is to efficiently store, transport, feed and supply bulk solids to processing units whenever needed. The ability to provide expert solutions to a wide range of industries derives from a team of experts who have many years of experience in the design, production and installation of bulk material handling systems. Each phase of a bulk material handling project is critical to achieving desired performance and required safety. Our team of highly experienced engineers provide industrial solutions designed for safety and reliable performance. There exist several aspects that affect system design and each of these aspects should be considered carefully to achieve an efficient bulk material handling solution. Physical and chemical properties of bulk materials (bulk density, particle size, angle of repose, flowability, moisture, corrosivity, minimum ignition temperature etc.), conveying capacities, storage, process limitations, and connected equipment are some of the important factors in system design. Process and occupational safety considerations are also key elements in engineering design. Being a solution provider in the bulk solids handling industry with over 40 years of experience, our strength comes from R&D, custom design and production capabilities for each application. Our operational organizations are flexible enough to supply problem free solutions for our customers from a single equipment production to complete turnkey system installation in a short time.

Polimak

2 products found

Polimak products

Industrial Solutions

Pneumatic Conveying Systems

Pneumatic conveying systems are broadly used throughout bulk material handling industries to move dry bulk materials through a facility. They move the bulk material in a pipeline generally with air being used as a conveying agent. When it comes to utilising pneumatic conveying systems to transport dry bulk materials, facility owners find themselves in a position to of needing to make a choice between pressure conveying or vacuum conveying. In other operations, a combination of both, vacuum and pressure conveying systems may be the best solution. Ultimately, Polimak experts will have to consider what is feasible given the available resources and suggest which method will best suit the transportation of the bulk material.