QS Advanced Materials Inc products

Elements

Boron Nitride Crucible

HBN is produced by sinter the boron nitride powder/flake together into a solid material. The maximum size of material is limited by the power and dimensions of the hot pressing equipment. Since hexagonal boron nitride is a quite soft ceramic, it is machinable. Hot pressed boron nitride we supplied could be machined into all kinds of customized shapes, as long as the design is smaller than the raw material block. As the price for raw material (BN solid) is rather high(>$20/inch3), price for simple shape products, e.g. crucibles, can be frequently estimated based on the quantity of BN solid it consumed.

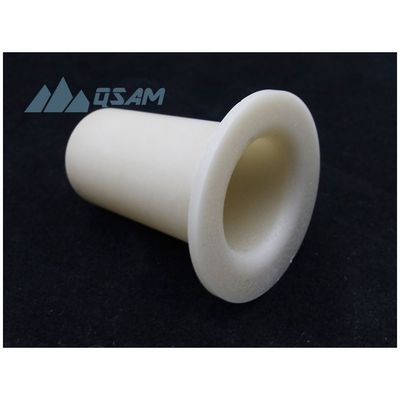

Aluminum Nitride Crucibles

Aluminum nitride (AlN): Aluminum nitride (AlN) ceramic material was found to be promising in microelectronics applications, due to its very high thermal conductivity and property as an insulating ceramic. Recently, the most common application for aluminum nitride is substrate for electronics or chip carriers. Along with PBN crucibles, AlN is also one of the selected materials to build crucibles for grow crystals of GaN (gallium nitride). Aluminum nitride crucibles could withstand about 1300°C in air, without bulk oxidation, although the process started after 700°C. In vacuum, AlN decompose at 1800°C. AlN melts at 2200°C, with inert atmosphere protection. In general, the working temperature for AlN products is 800°C in air, 1700°C in vacuum and 2100°C in inert atmosphere.

Advanced Ceramics

Aluminum Nitride (AlN) Crucibles

Aluminum nitride (AlN) ceramic material was found to be promising in microelectronics applications, due to its very high thermal conductivity and property as an insulating ceramic. Recently, the most common application for aluminum nitride is substrate for electronics or chip carriers. Along with PBN crucibles, AlN is also one of the selected materials to build crucibles for grow crystals of GaN (gallium nitride). Aluminum nitride crucibles could withstand about 1300°C in air, without bulk oxidation, although the process started after 700°C. In vacuum, AlN decompose at 1800°C. AlN melts at 2200°C, with inert atmosphere protection. In general, the working temperature for AlN products is 800°C in air, 1700°C in vacuum and 2100°C in inert atmosphere.

Boron Nitride Tubes

High purity boron nitride tubes could withstand higher temperature in vacuum than lower purity boron nitride tubes. Although we usually claim the maximum working temperature as 2500C, there`s record to use our material at 3000+ C. Due to the low wettability with metals, boron nitride is an ideal material to handle molten metals, especially for high purity material metal in vacuum. QS Rare Elements could custom make all kinds of tubes in about 2 weeks with $200 MOQ. Typical boron nitride tubes are smaller than 12" dia x 12" length due to the limitation of our equipment. Boron nitride tubes could be connected together to make longer boron nitride tubes, with flat or threaded joint presented below. Other forms of boron nitride tubes could be available with drawings.

Deposition Materials

Telluride Sputtering Targets

Telluride is a quite common material for sputtering targets. As Te is somehow a metal, tellurides are actually quite close to alloys of certain metal and Te. Most of telluride sputter targets we supplied are still made by hot pressing technique, as the process control for VIM method is quite hard for telluride material and obtain quite bad results a lot. Telluride sputter targets are usually used in optics and electronic industries.

High Purity Materials

Alpha-Alumina (Al2O3) Pellet, 99.999% Ultra High Purity Grade

is the raw material for sapphire crystal. This type of pressed pellets are made from ultra high purity alumina. It is designed to provide high filling in crucibles used to make sapphire single crystals. The alumina materials QSRE supplied are produced with latest eco-friendly and high technology. As a supplier for advanced materials, we continuously improving the service by cooperate with the manufacturers with high efficiency large volume production. High purity Al2O3 materials we delivered are frequently have applications in production of Magnetic recording media. Monocrystal (sapphire, garnet, etc.). Translucent ceramics. Fluorescent materials. Thin film coating (PVD).

Refractory Metals

Tungsten Metal Products

Tungsten crucible has the best heat resistance of all metal crucibles. Smaller tungsten crucibles are machined from tungsten rods while larger tungsten crucibles are directly sintered by powder metallurgy technology. Tungsten resource is now dominated by China and Russia for a long time. Taking advantage of its local office in Shanghai, QS Rare Elements is importing and contract manufacturing tungsten crucibles and other tungsten products from Chinese top, certified manufacturers. We accept custom manufacturing request for both R&D and manufacturing.