QS Advanced Materials Inc products

Elements

Boron Nitride Crucible

HBN is produced by sinter the boron nitride powder/flake together into a solid material. The maximum size of material is limited by the power and dimensions of the hot pressing equipment. Since hexagonal boron nitride is a quite soft ceramic, it is machinable. Hot pressed boron nitride we supplied could be machined into all kinds of customized shapes, as long as the design is smaller than the raw material block. As the price for raw material (BN solid) is rather high(>$20/inch3), price for simple shape products, e.g. crucibles, can be frequently estimated based on the quantity of BN solid it consumed.

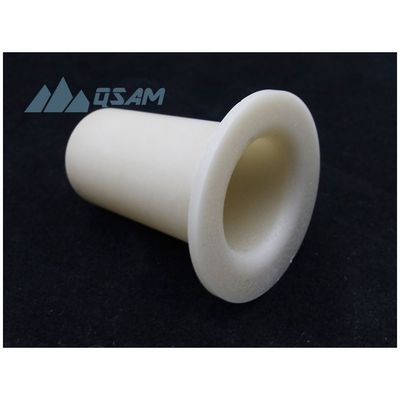

Aluminum Nitride Crucibles

Aluminum nitride (AlN): Aluminum nitride (AlN) ceramic material was found to be promising in microelectronics applications, due to its very high thermal conductivity and property as an insulating ceramic. Recently, the most common application for aluminum nitride is substrate for electronics or chip carriers. Along with PBN crucibles, AlN is also one of the selected materials to build crucibles for grow crystals of GaN (gallium nitride). Aluminum nitride crucibles could withstand about 1300°C in air, without bulk oxidation, although the process started after 700°C. In vacuum, AlN decompose at 1800°C. AlN melts at 2200°C, with inert atmosphere protection. In general, the working temperature for AlN products is 800°C in air, 1700°C in vacuum and 2100°C in inert atmosphere.