R3 Environmental Systems products

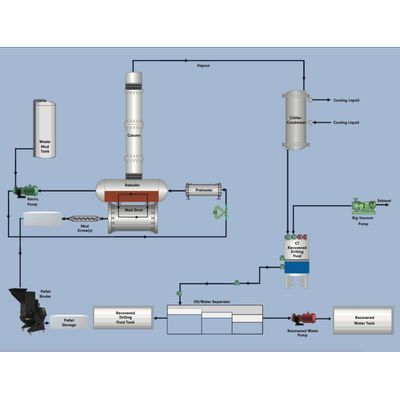

Drilling Fluid Recovery

Soil Remediation

R3 Environmental Systems owns and operates two types of state-of-the-art Low Temperature Thermal Desorption (LTTD) units that facilitate effective soil treatment. Both the Thermal Desorption with Destruction and Thermal Desorption with Recovery technologies are mobile and have been engineered to meet the most stringent health and safety standards. Contaminants proven capable of being treated include: Petroleum Hydrocarbons, Polycyclic Aromatic Hydrocarbons (PAH), Creosotes, Coal Tars and Bunkers

Waste Oil Recovery

Waste oil treatment is the process of recovering valuable resources from waste oil for reuse. Typically, waste oils are contaminated with water and solids that render them unusable; waste oil treatment enables the recovery of valuable resources for reuse. Our state-of-the-art processing facility can recover valuable oils from many types of waste oils such as automotive and motor oils, hydraulic oils, aviation fuels, and industrial lubricants. R3’s proprietary treatment process separates the valuable hydrocarbons from the water and solids. Once this separation is complete, the extracted oil is “polished” to ensure that it meets the highest quality standards for use as an alternate fuel source.

Stabilization / Solidification

R3 Environmental Systems’ solidification and stabilization process is a safe and cost-effective method of treating contaminated materials. The process, which involves mixing Portland cement and various reagents like ash, bentonite, or activated carbon into contaminated materials, protects human and environmental health by immobilizing the contaminants within the treated material. The cement reacts with the water present in the contaminated material, changing its physical and chemical properties to prevent the escape of the contaminants into the environment. The United States’ Environmental Protection Agency has identified stabilization and solidification as a “best demonstrated available technology” for the treatment of more than 50 types of contaminants. The process is gaining in popularity across key sites in Canada, contributing to the sustainable redevelopment of urban and industrial properties.