- Home

- Companies

- Waste and Recycling

- Recycling Systems

- Redoma Recycling AB

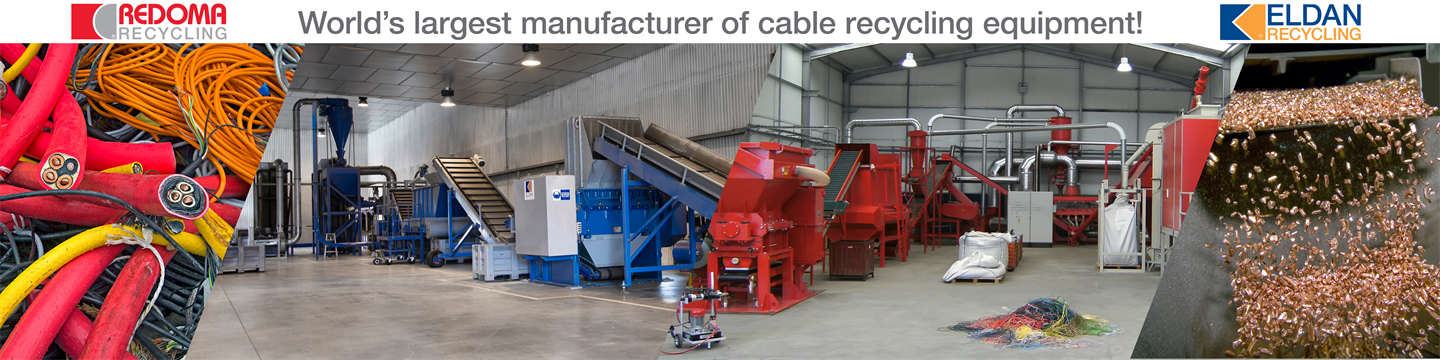

Redoma Recycling AB

Redoma Recycling AB is a leading manufacturer of small and medium-sized cable recycling plants. Worldwide we have successfully installed more than 350 cable plants under the brand name System Redoma. Together with Eldan Recycling A/S we form Eldan Group, forming the world’s largest manufacturer of cable recycling equipment with 90 years of joint experience. Traditionally we are offering three types of cable recycling lines providing cost-efficient tailor made system solutions for capacities from 150 kg/h up to 1700 kg/h: Thunderhawk, Powerkat and Firefox. Our machinery is built for tough working conditions providing a perfect solution for every customer! It is well known for its high quality, flexible design and reliability.

Company details

Find locations served, office locations.

- Business Type:

- Manufacturer

- Industry Type:

- Recycling Systems

- Market Focus:

- Globally (various continents)

- Year Founded:

- 1984