Sanborn Technologies products

High Speed Disc Centrifuge Systems

Sanborn - Automatic Self-cleaning Coolant Recycling System

The Sanborn “CP” Systems are the most efficient and effective coolant recycling systems in the industry. The heart of the CP system is the Mitsubishi self-cleaning high-speed disc centrifuge that provides highly effective coolant purification by removing fine solids and tramp oil down to negligible levels for pristine coolant recycling.

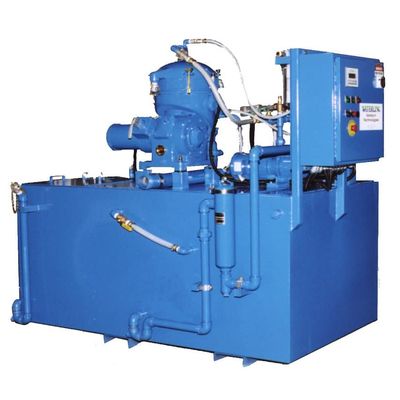

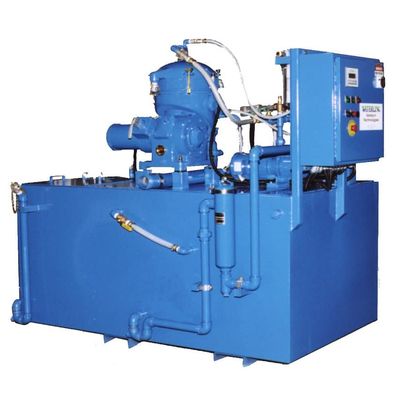

Sanborn - Patriot IFR Fluid Recycling System

The Sanborn Patriot IFR Integrated Fluid Recycling System is a fully integrated system that is the best available technology metal working coolant recycling. The Patriot is equipped with a Mitsubishi self-discharging high-speed disc centrifuge for the removal of the finest solids to ≤1-micron range and tramp oil removal down to 0.0025%. The Patriot IFR is the right choice operate as a fully automated centralized coolant recycling system in the facility to service coolant sump carts.

Pioneer IFR System - Pioneer IFR System

The Sanborn Pioneer IFR is a Fully Integrated Fluid Recycling Centrifuge System that is the best available technology metal working coolant recycling and fluid purification. The heart of the Pioneer System is a Mitsubishi self-discharging high-speed disc centrifuge provided for the removal of metal fines and solids down to ≤1-micron range and tramp oil removal down to ≤0.0025%. These systems are excellent to process coolant from either a set of customer-supplied tanks or to process from centralized coolant systems on a “slip stream” dialysis basis.

Microfiltration Systems

AquaMATE - Model MF - Aqueous Bath Purification System

System is constructed of corrosion resistant process components such as the Polypropylene Tank and Skid, CPVC Piping and SS MF Circulation Pump, etc.

Aqueous - Wash Tank Filtration System

Designed for specifically for recycling and disposal or aqueous wash tanks, the Sanborn Aquamate membrane filtration systems can filter solutions up to 180°F and pH of up to 13. Processing rates range from 200-2,000 gallons per day.

Centrifuges

Sanborn - Turbo Centrifuge Systems

Sanborn - LiquaPac HS – TMC Tank Mounted Series

Sanborn - Model LiquaPac HS – RCS Series - Centrifuge System

The LiquaPac HS RCS Centrifuge System is our most common version of the LiquaPac HS manually clean centrifuge. The RCS Centrifuge systems are provided complete with centrifuge feed pump(s), clean coolant supply pump(s). The RCS Centrifuge Systems come mounted on our unique clean/dirty tank system that allows closed loop multi-pass processing through the centrifuge to maintain continuous recirculation of the metal working coolants within RCS tank, without the need of level controls. These cost-effective LiquaPac HS Centrifuge Systems provide a high level of Coolant Recycling and liquid solids separation without the excessive costs typically associated with competitive centrifuges.

Centrifuges - High-Speed Disc Centrifuges

Sanborn - Automatic Self-cleaning Coolant Recycling System

The Sanborn “CP” Systems are the most efficient and effective coolant recycling systems in the industry. The heart of the CP system is the Mitsubishi self-cleaning high-speed disc centrifuge that provides highly effective coolant purification by removing fine solids and tramp oil down to negligible levels for pristine coolant recycling. All CP Systems include Sanborn`s proprietary mixing system in the dirty coolant tank that maintains a homogeneous feed to the centrifuge for effective coolant purification. This process will completely mix the tramp oil and solids for effective removal in the three-phase high speed disc centrifuge for superior separation performance to maximize coolant recycling and at the same time minimizing spent coolant waste.

Sanborn - Patriot IFR Fluid Recycling System

The Sanborn Patriot IFR Integrated Fluid Recycling System is a fully integrated system that is the best available technology metal working coolant recycling. The Patriot is equipped with a Mitsubishi self-discharging high-speed disc centrifuge for the removal of the finest solids to ≤1-micron range and tramp oil removal down to 0.0025%. The Patriot IFR is the right choice operate as a fully automated centralized coolant recycling system in the facility to service coolant sump carts.