Semicorex Advanced Material Technology Co.,Ltd. products

Silicon Carbide Coated - PSS Etching Carrier

Semicorex - Etching Carrier Holder for PSS Etching

Semicorex`s Etching Carrier Holder for PSS Etching is engineered for the most demanding epitaxy equipment applications. Our ultra-pure graphite carrier can withstand harsh environments, high temperatures, and harsh chemical cleaning. The SiC coated carrier has excellent heat distribution properties, high thermal conductivity, and is cost-effective. Our products are widely used in many European and American markets, and we look forward to becoming your long-term partner in China.

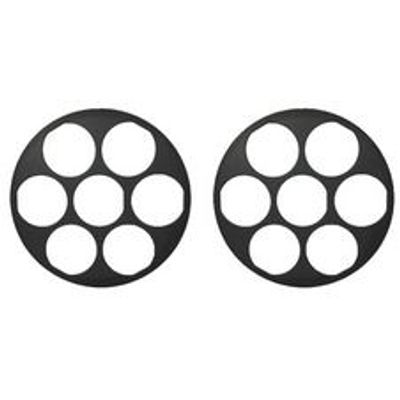

Semicorex - PSS Handling Carrier for Wafer Transfer

Semicorex`s PSS Handling Carrier for Wafer Transfer is engineered for the most demanding epitaxy equipment applications. Our ultra-pure graphite carrier can withstand harsh environments, high temperatures, and harsh chemical cleaning. The SiC coated carrier has excellent heat distribution properties, high thermal conductivity, and is cost-effective. Our products are widely used in many European and American markets, and we look forward to becoming your long-term partner in China.

Silicon Carbide Coated - ICP Etching Carrier

Semicorex - Model SiC - Coated ICP Component

Semicorex`s SiC-Coated ICP Component is designed specifically for high-temperature wafer handling processes such as epitaxy and MOCVD. With a fine SiC crystal coating, our carriers provide superior heat resistance, even thermal uniformity, and durable chemical resistance.

Semicorex - Model SiC - High-Temperature Coating for Plasma Etch Chambers

When it comes to wafer handling processes such as epitaxy and MOCVD, Semicorex`s High-Temperature SiC Coating for Plasma Etch Chambers is the top choice. Our carriers provide superior heat resistance, even thermal uniformity, and durable chemical resistance thanks to our fine SiC crystal coating.

Semicorex - ICP Plasma Etching Tray

Semicorex`s ICP Plasma Etching Tray is engineered specifically for high-temperature wafer handling processes such as epitaxy and MOCVD. With a stable, high-temperature oxidation resistance of up to 1600°C, our carriers provide even thermal profiles, laminar gas flow patterns, and prevent contamination or impurities diffusion.