Sepragen Corporation products

Chromatography Systems

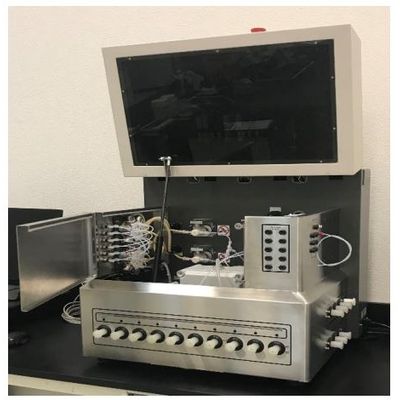

QuantaSep - Pilot/Production Chromatography System

The QuantaSep® 100 pilot/production chromatography system for fluid handling and control is composed of three modules, integrated into a single cabinet with dimensions of 30" width x 24" depth x 18" height and weighing 125 lbs.

QuantaSep - Fully Integrated and Completely Automated Chromatography System

QuantaSep® 1000 is a fully integrated and completely automated chromatography system capable of flow rates between 10 ml/min up to 1 Liter/min (higher or lower flow rate ranges also available upon request). With its powerful Windows®-based software, it allows the user to automatically equilibrate, load, wash, and elute up to three columns. It also permits the user to control each step in the purification based on one or more measured variables (UV, pH, conductivity, time, temperature, air sensors or any external user-defined monitor).

QuantaSep - Chromatography Systems

QuantaSep 1800 is a fully integrated system to truly automate your purification process. This sanitary bench top system has a large dynamic flow range of 20-1,800ml/min and enables the user to automatically equilibrate, load, wash, elute and regenerate up to three columns.

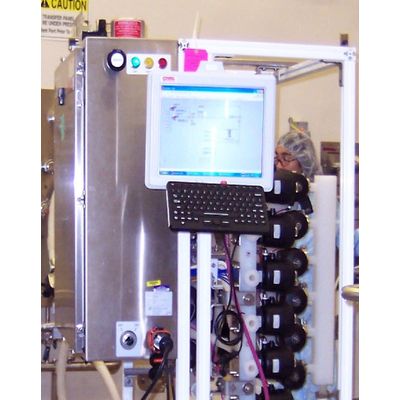

QuantaSep - Process Automated Chromatography System for Clinical Production

The QuantaSep® 5000 system is mobile, compact, and capable of providing an operating flow range of 50ml-5L/min. The integrated system has two positive displacement pumps, 8 buffer selection valves, inline mixer, filters and 6 fractions collection valves. It has capabilities of buffer switching, gradient formation, feed pre-filtering, air ejection, conductivity and pH sensing pre and post column, forward and reverse flow in a powerful easy-to-use software package. The software enables buffer and fraction switching based on process conditions and alarms in the event of overpressure, air or leaks. All events are logged and archived.

QuantaSep - Compact Mobile Process Chromatography System

The QuantaSep® 10000 process chromatography system is mobile, compact and capable of providing an operating flow range of 100ml – 10 liters/min. This sanitary system consisting of disposable tubing can process a 3000+ liter cell culture batch in one shift! It is ideal for GMP manufacturing. The integrated system has two positive displacement pumps, 8 buffer selection valves, inline mixer, filters and 6 fractions collection valves. It has capabilities of buffer switching, gradient formation, feed pre-filtering, air ejection, conductivity and pH sensing pre and post column, forward and reverse flow in powerful easy-to-use software package. The software enable buffer and fraction switching based on process conditions and alarms in the event of overpressure, air or leaks. All events are logged and archived. Precision pumping and mixing enables on-line dilution from buffer concentrates.

QuantaSep - Chromatography Custom Skids

Sepragen Corporation has been helping customers with their custom chromatography needs for over a decade. No two chromatography processes are alike. Some require low flow rates, some high flow rates; some use alcohol or other flammable solvents and require explosion proof design and certification; others need to run in a cold room; some need stand alone control while others may need to communicate with an in-house SCADA or DCS; and some may require a polymeric or even a disposable flow-path while others may require a robust stainless steel construction. In such cases when of the shelf solutions don’t work, customers often go down the trap of having either their engineers design their own systems in house or having their engineering companies outsource the skid fabrication from third party fabricators.

QuantaSep - Dual Range Lab/Pilot Hybrid Development and Scale-Up Chromatography System

QuantaSep® 1000LX is a unique integrated system that enables low flow methods development and high flow scale up in one machine. With its powerful Windows®-based software, it allows the user to automatically change buffers, collect fractions, and run gradients. The user can control each step in the purification based on UV, pH, conductivity, time, volume, air sensors or any external user-defined variable. All event, alarm, method, and chromatography data is logged for analysis or archiving. When methods development is complete, simply switch to the higher flow tubing to scale-up and make clinical product.

Other

Sepragen - Chromatography Columns

Superflo Columns were invented to help overcome the problems faced by bioprocess engineers and scientists as they scale up chromatographic processes from the laboratory to production scale. Superior performance at extremely low pressures and high flow-rates in small footprint columns are the main advantages of the Sepragen’s Superflo and Wedge columns.

Sepragen Express - Bio Reactor

The patented Express® Bioreactor represents a Paradigm shift in culturing cells. Cells are grown on a bee- hive like spongy matrix which is suspended in a sterile chamber in an atmosphere of air/ CO2. This provides a high surface area and high oxygen availability for growing both suspension and anchorage-dependent cells. The cells can be grown in a batch, fed-batch or perfusion mode. The Express® Bioreactor is disposable, comes pre-sterilized and can be easily set up in a standard air/ CO2 incubator.

Sepragen - Sepraflo Resins

Sepragen’s Sepraflo Resins are designed for process scale separation of biological molecules. They can be run at very high flow rates, typically up to 50% higher than commonly used resins from other suppliers. They have large nominal 300A pore size that facilitates rapid mass transfer of large macromolecules and provides for high static and dynamic binding capacity. They are cleanable with 1N sodium hydroxide.