Sono-Tek Corporation products

Equipment Solutions

SonoFlux - Stationary Ultrasonic Spray Fluxing System

Stationary ultrasonic spray fluxing system for low mix/dedicated lines with medium to high volume. No moving parts mean ultra-low maintenance and the highest reliability and is compatible in all major wave solder machines. All SonoFlux systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance with up to 80% reduction in flux consumption.

SonoBraze - Ultrasonic Brazing System

Designed to be retrofitted onto existing lines, SonoBraze is ideal for spraying aluminum brazing fluxes onto targeted areas. The system is a complete solution that includes the non-clogging ultrasonic nozzle(s), flux recirculation, and controls. SonoBraze is ideally suited for Paint F Flux and standard brazing flux, and typically reduces consumption by 60% while reducing maintenance by over 90%.

FlexiCoat - Automated Ultrasonic Spray Coating System

Fully automated, programmable standalone system with coordinated XYZ motion control using Windows-based software and user-friendly teach pendant with trackball. Versatile mid to high-volume or pilot scale production thin film coatings. Can be configured with standard SMEMA conveyor for inline coating solutions.

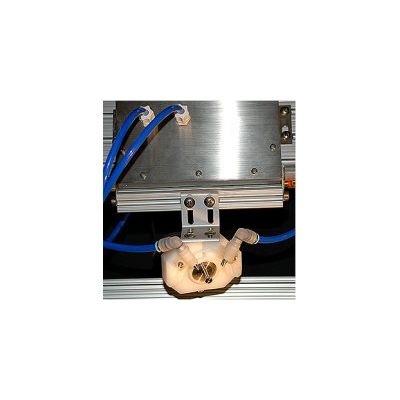

WideTrack - Wide Area Ultrasonic spray Coating System

Designed to be added to an existing line spraying up or down, the WideTrack ultrasonic spraying system produces a wide, fan-shaped spray pattern using no moving parts. The system features: uniform, repeatable thin film coatings, widths available up to 24” and proven performance for mid to high volume production operations.

Sono-Tek - Solder Recovery System

The Solder Recovery System enables PCB manufacturers to recycle solder onsite directly from their wave solder machines. The EVS by Sono-Tek solder recycling system saves up to 50% in solder costs in the wave soldering process.

SonoFlux - Ultrasonic Fluxing System

An economical reciprocating ultrasonic spray fluxing system for medium to high mix lines. Easy integration and operation with all major wave solder machines. All SonoFlux systems feature non-clogging, repeatable, low maintenance ultrasonic spray performance with up to 80% reduction in flux consumption.

Ultrasonic Spray Fluxers for Selective Wave Solder

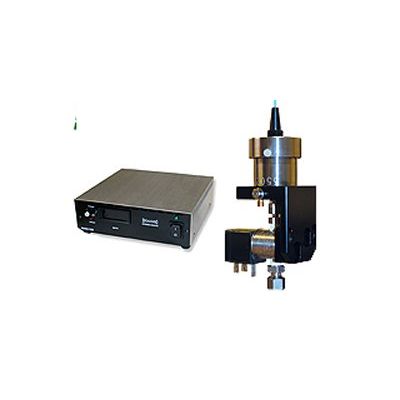

SelectaFlux - Ultrasonic Selective Fluxing System

For selective fluxing applications, Sono-Tek’s ultrasonic selective fluxing system offers the highest degree of accuracy and fine line control in the selective fluxing industry. Controlled velocity spray will not harm or disturb components while giving maximum top side fill in selective fluxing applications.

SelectaFlux - Ultrasonic Spray Coating System

Sono-Tek’s SelectaFlux Inline ultrasonic selective spray fluxing system is a standalone PCB selective fluxing system incorporating our precision SelectaFlux ultrasonic nozzle. The system is fully programmable, SMEMA conveyor optional with pallet sensing capability and board stops for production volume printed circuit board manufacturing. This programmable three-axis small footprint platform brings quality, consistency, and reliability to your flux coating process while improving transfer efficiencies (up to 99%). Coverage areas are limited to a desired pre-programmed region. This eliminates the masking, demasking, and rework evident in most other application methods.The SelectaFlux In-line system can be configured for a conveyorized process or outfitted with an adjustable fixture for a manually fed batch application.