Spiessens Machinebouw products

Conveying Systems

Speissens - Automatic Belt Correction Conveyors

These adaptable conveyors are equipped with automatic belt correction. When the belt shifts to much to one side during rotation this is corrected automatically. The end of the conveyor can be extended a few centimeters, this way the conveyor can be integrated in the processing line perfectly. These conveyors are mobile, but can be secured in one place with the aid of special feet. The belt can be lifted to thoroughly cleaned. A scraper at the end ensures that no residu remains on the belt.

Speissens - Vertical Conveyor Belt

Elevators have already proven to be indispensable pieces of equipment to vertically transport various products like grains, pellets, powders, etc. It is a type of conveyor belt used to cross height differences. The belt is equipped with ribs or buckets to take the product upwards. The elevator has a very slanting or even a completly vertical angle. Large conveying heights of more than 175 m are feasible. We offer maximum wear resistance, even with highly abrasive materials. This type of vertical conveyor can be constructed in various heights and widths, depending on the client’s wishes. The elevators are naturally designed according to valid norms and regulations, and delivered with mandatory documentation.

Speissens - Redler Chain Conveyor

In a redler chain conveyor we use transverse bars, fixed to one or two powered chains. They transport the dry product over a bottom plate. The product can automatically be fed from the top or the sides and discharged through holes on the bottom. Various distribution opportunities can be created between different outputs, by installing sliding gates in various places at the bottom. There is no dust flying around, because it is contained within the transport system. Optionally, the airborne dust can be suppressed by installing an automatic sprinkler system. Redlers are a very hygienic way to transport goods. Foreign objects can’t reach the product and there is no loss under the machine. A slope up to 60° is feasible. For steeper slopes we recommend using an elevator

Speissens - Buffering Roller Conveyor

During the transport on a buffering roller conveyor, piece goods can be stopped by a bar at the end which buffers the product. The rollers hang in between two powered chains and once the product has been stopped, they still spin underneath the product.

Speissens - Transport Roller Conveyor

With the transport roller both piece goods and bulk goods conveyor can be transported on a low-cost manner, over a great length. This can be done both driven or with the aid of gravity, depending on the slope.

Custom Machinery

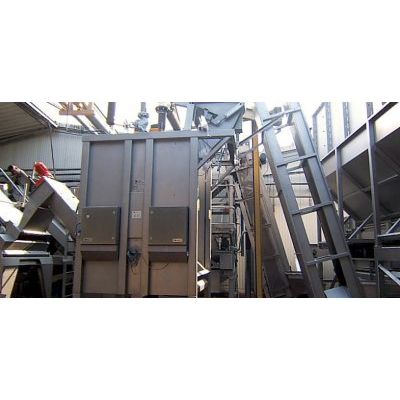

Speissens - Walkway Construction for Machine Maintenance

Every client wants his machines to be well accessible for maintenance and cleaning. That is why we have achieved great expertise in constructing walkways where the machines are easily and safely accessible. As guidelines for construction we use the safety documents of the current machine guidelines. The walking surfaces can be grids in galvanized steel, stainless steel or plastics and full plate in diamond plate or wood. Handrails can be made functional and budget friendly without neglecting the design.

Speissens - Unraveling Mill for Concrete Mixing

We designed and patented a system to unravel tiny steel needles, to make it easier to make precise doses for the creation of reinforced concrete by mixing the needles and concrete.

Speissens - Homogenizer for Sauce Production

Homogenizers are particularly suited to produce sauces and the like. The new knife aggregate 159 M is adjustable, so that we have two different treatments, namely, homogenize and mix, dependant on the position of the knife aggregate. Because of this, it’s possible to make a homogeneous substance in only one process and add chunky elements afterwards. Machines that are equipped with the adjustable knife aggregate are very suitable to mix, stir, spread and homogenize anything from liquid to strongly viscous products.

Speissens - Sand Bag Filling Machine for Jute Bag Filling

The sand bag filling machine is designed by Spiessens to automatically fill jute bags with sand. The sand is dumped into a bunker and transported to the filling station. Here, a bag is clutched and filled with sand. After that, the bag is guided to the sewing machine, where the bag is closed up. The closed bag is then transported to a container or other storage facility. This large model of the machine is mounted on a container for ease of transport.

Speissens - Weighing and Dosing Systems

Often bulk goods need to be packaged in bags, cardboard boxes or trays. To do this we constructed a number of readymade systems for potatoes, vegetables, fruit, meat, fish, but also dry cakes and confectionery. In the non-food we have lots of experience cement, mortar and even wet and dry concrete.