Stokkermill | Seltek Srl products

Plants - Recycling Plants

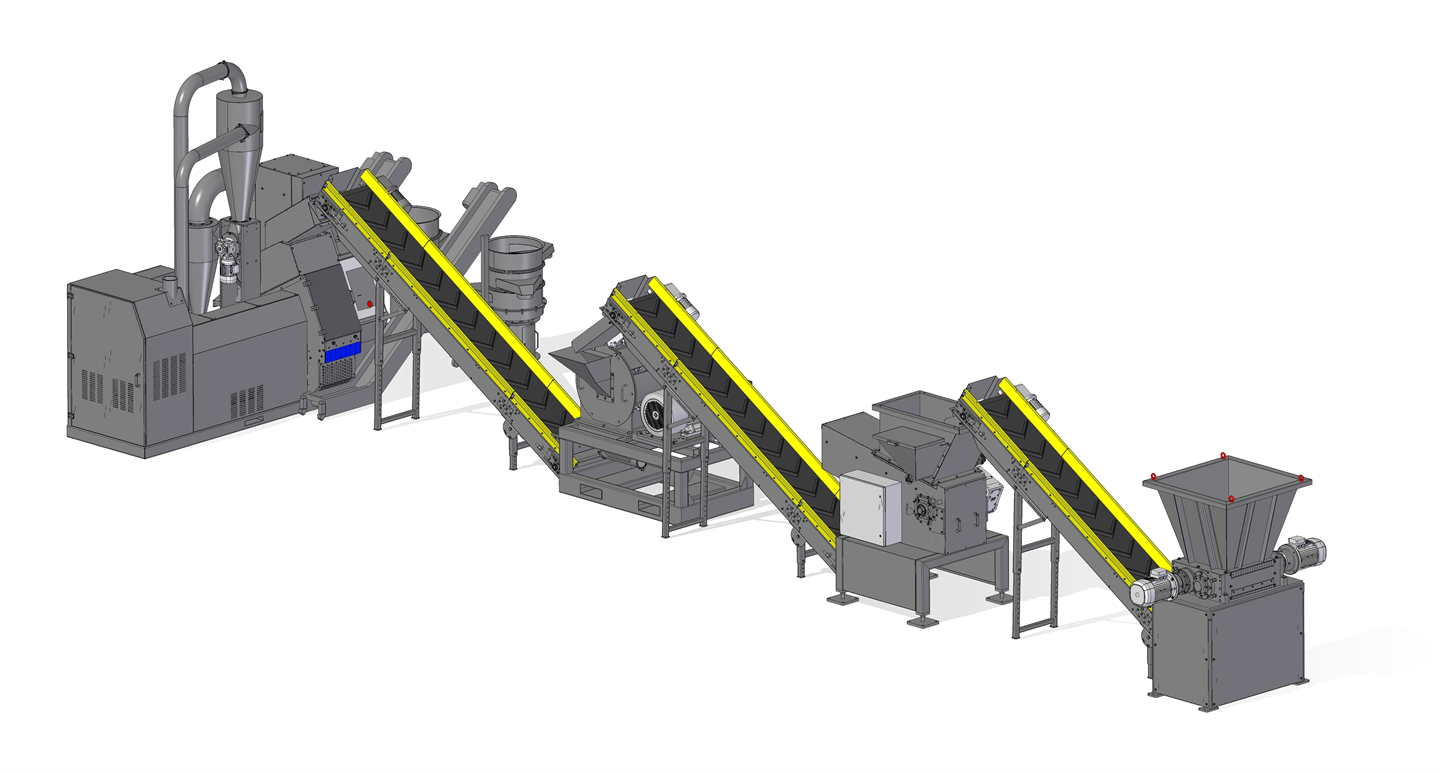

Stokkermill - Copper Cable Recycling Line

Recycling line for copper cables and wiring, copper and aluminum, special cables and cabling from vehicle dismantling. Copper cable recycling line, for the treatment of copper and aluminium cables allow to treat high quantities of material obtaining an exceptional quality of the output product and the same technical and constructive excellence that characterizes the Stokkermill models. Specially designed to provide a complete recycling solution for the treatment of copper cables, aluminium cables, cables, and wiring, through a combination of technology: mill, air flow knives and vibrating table, and guarantee a high use of materials and a purity of 99.9%.

Stokkermill - Aluminium Shredding Plant

Aluminium shredding plant, line for aluminium scrap or ELV's (end-of-life vehicles), allows the recovery, reduction and separation of aluminum waste, inerts or metals. Aluminium shredding plant is designed to refine the input material from inert fractions and ferrous metals. The recycling plants allow to obtain a high-quality aluminium proler allowing the delivery directly in the foundry avoiding further preparation activities. Aluminium scrap recycling plants improve economic performance. Aluminium scrap treatment plants are extremely flexible and versatile and allow to treat aluminium profiles, aluminium tins, and general aluminium scrap.

Shredders - Single Shaft

Stokkermill - Single Shaft Pre Shredder

Primary single shaft pre shredders, copper shredders, aluminum, non ferrous metals, electric and electronic scrap. The single-shaft pre shredder of the Stokkermill PS range, with hydraulic pusher, are available in three models of variable dimension and power with capacity from 200 kg/h to over 2,000 kg/h. The rotating blades of the PS primary shredder are reversible and made of wear-resistant alloy. The industrial pre-shredders are equipped with classifier screens of different diameters allowing to vary the output size in accordance with the user requirements. The efficient hopper opening system allows a quick replacement of the screens, making easy and simple the maintenance activities, the replacement and adjustment of the blades. The electrical panel is equipped with a PLC system for the control of the operating parameters that includes the reversal of the rotor in case of over-loading.

Stokkermill - Single Shaft Shredder

Single shaft shredder, single shaft primary shredder for copper, aluminium, tyre, electric, electronic wires, WEEE scrap and industrial waste. Single shaft shredder CSR allow the grinding and the volumetric reduction of tenacious materials and electronic industrial waste and can be driven by electric or hydraulic power units. Single-shaft shredders - CSR series can be connected to granulators for recycling cables and radiators of the TURBO and Multi-Flex Turbo Zig-Zag series or, alternatively, they can perform the function of the primary roughing machine to increase the productivity of already existing lines. The selection grids, available in different sizes, allow to obtain the required size at the first step. The electronically controlled hydraulic power box and rotation inversion system allow to optimize the production parameters according to the material to be treated.

Shredders - Twin Shaft

Stokkermill - Twin Shaft Industrial Shredders

Primary reducer rotary sherar for scrap metals, e-scrap and e-waste. The range of Twin Shaft industrial shredder D series – electric or hydraulic drive – has been designed for shredding many types of materials and mainly for the first volumetric reduction.

Other

Stokkermill - Four Shaft Industrial Shredder

The range of Four Shaft industrial shredder F series – electric or hydraulic drive – has been designed for shredding many types of materials and getting a controlled output size thanks to the use of classifier screens.

Stokkermill - PCB Boards and E-scrap Recycling System

Stokkermill has developed a range of machines (Compact PCB) and recycling lines (PCB LINE) easy to use and maintain to enable the recycling of electric and electronic boards, printed circuit boards, motherboards (PCB), e-waste in general.

Stokkermill - Electric Motors Recycling Systems

Stokkermill E-MotorChop is an equipment designed for recycling the electric motors. It is very compact, with low energy consumption.

Stokkermill - Hammer Mills

The Stokkermill HM hammer mills reduce the size of the materials to enable separation and cleaning activities. Stokkermill designs and manufactures small and medium size hammer mills which are characterised by robustness and simplicity in maintenance thanks to the hydraulic opening system of the crushing chamber.Stokkermill - Vertical Compacting Presses

Stokkermill VT vertical compacting presses are the ideal solution wherever is necessary to reduce the waste volume such as paper, cardboard, plastics, various packaging, PE and PET bottle.