SVCS Process Innovation s.r.o. products

SVCS - Horizontal Furnaces

Designed for High Performance in Production Environment while stays Efficient and Economic

SVCS - Vertical Thermal Reactor (VTR)

SVCS Vertical Thermal Reactor (VTR) is designed for all standard atmospheric and low pressure CVD processes. VTR is available with several lengths of flat zone for both mass production and R&D application. The single tube set-up with dual boat logistics is optimized for minimum down time as well as low maintenance costs.

SVCS - Compact Tabletop Furnaces System

The SVCS Tabletop Furnace system provides a semiconductor grade quality tool for universities, R&D laboratories and pilot fabs. This system can be used for wide range of processes due to outstanding flexibility and amount of optional modules available to meet special and often unique requirements of every customer.minimised footprint and low cost of ownership while offering high process flexibility.

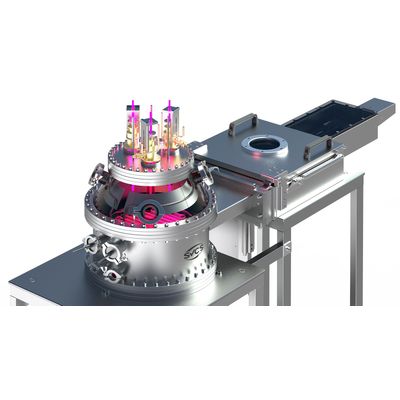

SVCS - Single Wafer Reactors

ALD Reactor with combined MW surfatrons and ECWR plasma sources. Within international R&D project we developed together with ISAC Research (Korea) this unique reactor including the ALD gas panel for metal oxide and metal nitride thin film depositions on wafers with sizes up to 300 mm. Thus, we are not limited by standard wafer sizes, we can make substrate holder for any type of wafer. Perfect solution for R&D laboratories and Institutes. For example – we can make it for batch deposition on five 100 mm wafers, etc.

SVCS - Ultra High Purity Gas Delivery Systems

SVCS takes advantage of many years of experience in manufacturing tailored gas panels and gas systems for various wafer production technologies, as well as various R&D customised panels. SV DELI gas delivery system family offers a high level of technical design, components from the world leaders and a fully automatic control system with independent safety functions.

SVCS - Ultra High Purity Liquid Delivery Systems

Numerous semiconductor and photovoltaic manufacturing processes use source media available only in liquid phase. Sourcing and distribution systems for a safe and fully automated supply of processes with UHP liquid chemicals are part of our SVDeli product line. The key elements which guarantee safety, reliability and ease of handling have been specially developed for UHP liquids.

Bubbler - Precursor Temperature Controller

Many reaction constituents for semiconductor and PV processes are available only in liquid phase. We adopted suitable delivery systems to make them usable for technology process. One of the methods is based on liquid vapor pick-up by flowing gaseous media through the liquid. Flow of such carrier gas is controled by eletronic MFCs and is introduced to liquid container through a dip-tube while a carrier vapor mixture leaves the container through separate top outlet. In order to maintain the same pick-up rate during the whole process and from process to process, liquid media temperature has to be precisely controlled. We developed proprietary powerful combined cooling/heating engine for dry bath environment.

SVCS - Control System

SV-Con is a set of HW, SW and I/O interfacing. It’s development was supported by EU fundings and consulted by university and industry experts. System is fully modular and can be configured for horizontal/vertical thermal reactors, as well as other equipments used in semiconductor industry. SV-Con is ready both for installation in the new SVCS’s furnaces (SV-Fur and SV-Sol) and in other manufacturer’s refurbished equipment.