- Home

- Companies

- Swedish Exergy AB

- Products

Swedish Exergy AB products

Exergy - Air Stream Dryer

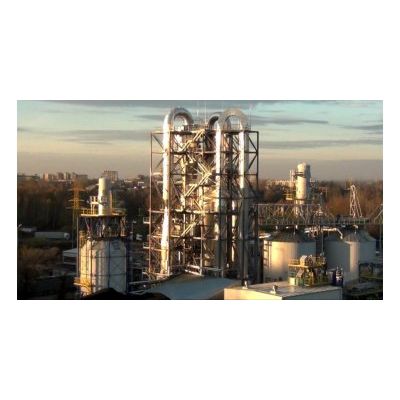

Exergy Air Stream Dryer is a semi-closed, low temperature dryer designed as stand-alone dryer or as a pre-dryer together with Superheated Steam Dryer (SHSD) for two stage drying. The drying air is indirectly heated in a heat exchanger using heating media such as low pressure steam, flue gases, hot water etc. Wet product is fed into the dryer via an air lock. The product is transported and dried in specially designed drying conduits and separated in an ultra-high efficiency cyclone or bag filter. The dried product is discharged from the bottom of the cyclone/bag filter through an air-lock. Part of the drying air can be recirculated back to the air heater to minimize drying energy need.

Exergy - Flue Gas Dryer

The Exergy Flue Gas Dryer was developed to meet the needs of the industry for the utilisation of latent heat in flue gases from boilers. The dryer consists of feeding and discharge equipment, a separation cyclone and specially designed drying conduits. The bio-mass is fed in hot flues gas stream and gets in direct contact with flues gases. The residence time is short and latent heat in flue gas can be used to dry the biomass to some extent. The technology is suitable for biomass with small particle size like bagasse, grass, other agro-residues etc. Direct contact flue gas drying has disadvantages of product contamination, limited drying possibility due to limited energy in flue gases, fire and explosion risk and corrosion risk if flue gas temperature is not properly controlled and can fall under dew-point leading to condensation.

Falling Film Evaporator

Falling film evaporators have been designed and developed by Exergy to be used mainly in conjunction with our Exergy Dryers. The low pressure steam from the Exergy dryer is used to generate clean steam to be used in steam turbines for electricity production, process heating etc. Other applications such as evaporation of leachate have been identified for this technology. A combination of falling film and forced circulation evaporators has been used where large volumes need to be concentrated to very small residual volumes such as in ethanol plants used in the sugar industry.

Exergy - Forced Circulation Evaporator

The Forced Circulation Evaporator has been developed over the past 20 years and we have specialized in treating difficult fluid wastes like oil emulsions, dissolved salts, heavy metals, radio-active and other hazardous chemicals, suspended solids etc. The main applications are concentration and/or recovery of oil emulsions, metal salts, leachate, organic solvents and other difficult waste water.