- Thermal Soil Remediation Equipment- Direct Fired Rotary Thermal Remediation Plants

- Thermal Soil Remediation Equipment- Indirect Fired Rotary Thermal Remediation Plants

- Hot Mix Asphalt Equipment - Counter Flow Drum Mixers/Dryers

- Hot Mix Asphalt Equipment

- Sand Drying

- Used Equipment - Direct Fired Plants

- Used Equipment - Plant Components

- Used Hot Mix Asphalt - Pugmills

- Used Hot Mix Asphalt - Primary Dust Collectors

Tarmac International, Inc. products

Thermal Soil Remediation Equipment- Direct Fired Rotary Thermal Remediation Plants

Tarmac - Model DF4.5: 4.5′ x 20′ Diameter - Direct Fired Thermal Plants

This rotary thermal soil remediation plant has only two loads. This thermal remediation system is easy to move and has a very small foot print. Thermal Soil Remediation projects can encompass light oils to heavy hydrocarbons as the Oxidizer is located before the Baghouse. Portable designs are available also with axles. Tarmac assembles thermal soil remediation plant when possible to improve quality. Shown in this photo is the mechanical assembly of Tarmac International`s two load rotary thermal soil remediation plant. Included, starting at the far side, is the feed bin, baghouse, rotary dryer, oxidizer, heat exchanger, and soil conditioner.

Tarmac - Model DF5.5: 5.5′ x 25′ - Direct Fired Thermal Plants

With only 4 major loads this plant is easy to move and has good production for remediation of soil. Rotary Thermal Soil Remediation Plant projects can encompass light oils to heavy hydrocarbons as the Oxidizer is located before the Baghouse. Portable designs are available. This plant is shown with an optional Acid Gas Scrubber to reduce sulfur and chlorine gases.This rotary thermal soil remediation plant is shown assembled in Birmingham, England and includes, from the forground, the feed bin, cyclone, dryer, soil conditioner, and baghouse over the soil conditioner. Not seen are the oxidizer, heat exchanger, baghouse, acid gas scrubber, and the control house.

Tarmac - Model DF7.0 - Standard 7′ x 27 Diameter - Direct Fired Thermal Plants

The Standard 7′ diameter rotary thermal remediation plant was the first size sent to Western Europe on a thermal treatment project in Germany. As this plant shows, the oxidizer is located before the baghouse due to heavy hydrocarbons. Equipment configurations can be made for light hydrocarbon contamination with the baghouse before the oxidizer. Feed Bin, Rotary Dryer, Oxidizer, and Baghouse frames are built at the dimension of a standard shipping container. Tarmac International, Inc.’s Standard 7′ diameter Rotary Thermal Soil plant has also been set up in Paris, France. Equipment shown on the left includes the feed bin, cyclone, and rotary thermal dryer. The right photo shows the oxidizer, heat exchanger, and baghouse.

Tarmac - Model DFS7 - Super 7′ x 27′ Diameter - Direct Fired Rotary Thermal Remediation Plant

The Tarmac Super 7′ diameter direct fired rotary thermal remediation plant is the same dryer shell as the Standard 7′ plant, but the air flow and down-stream air pollution control equipment has been increased in size to increase production. This increase allows for at 20% increase in production. Thus the cyclone, oxidizer, heat exchangers, baghouse, and optional acid gas scrubber have all been designed for increased gas volume and production. The Acid Gas Scrubber and Portability are available options.

Thermal Soil Remediation Equipment- Indirect Fired Rotary Thermal Remediation Plants

Tarmac - Model IND4.5: 4.5′ - Indirect Fired Thermal Soil Remediation Plant

The 4.5 x 40` Indirect fired rotary thermal soil remediation plant has only two major loads. This thermal remediation system is easy to move and has a very small footprint. Thermal Soil Remediation projects can encompass higher ranges of Parts Per Million hydrocarbons as found in waste pits and drill cutting. Portable designs are available also with axles. Tarmac assembles thermal soil remediation plant when possible to improve quality.

Model IND6.0 - 6` Indirect Fired Thermal Soil Remediation Plant

Tarmac`s 6` x 40` Indirect fired rotary thermal soil remediation plant has been designed to move as container sized loads. This thermal remediation system has a vertical equipment design and has a very small foot print. Thermal Soil Remediation projects can encompass higher ranges of Parts Per Million hydrocarbons as found in waste pits and drill cutting. Portable designs are available also with axles. Tarmac assembles thermal soil remediation plant when possible to improve quality.

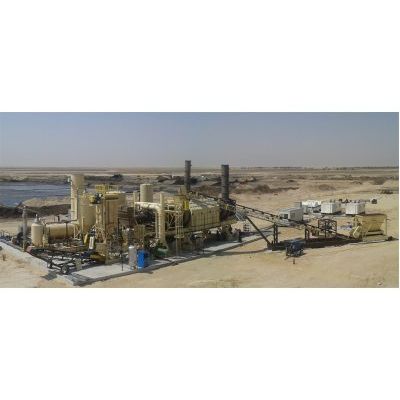

Model IND8.75 - 8.75` Indirect Fired Thermal Soil Remediation Plant

Tarmac designed and built this 8.75` diameter remediation plant. This triple shell, double pass indirect drying plant was installed in Kuwait. Another was installed in London. Oil and water were condensed and stored in separate product tanks.

Hot Mix Asphalt Equipment - Counter Flow Drum Mixers/Dryers

Tarmac - Model DM5.5 - 5.5` Counter Flow Aggregate Dryer / Drum Mixer

Portable or Stationary Units. 100 TPH to 150 TPH. Run up to 50% RAP (Recycled Asphalt Product). Slinger Feed Conveyor. Trunnion or Chain Drive. 1/2` Thick Shells. 3/8` Thick Adjustable Veiling Flights. Tarmac Combustion Flights Keep Material From Passing Through The Flame. Single Billet Rolled Drum Tires. Welded Flex Plate Tire Supports, No Bolts to Come Loose. Large 1045 Steel Trunnions. Twin Thrust Rollers to Prevent the Drum from Walking Off The Trunnions. Hauck Long Nose Burners, Multi-Fuel (Gas, Oil, Propane). Primary and Baghouse Dust Entry

Tarmac - Model DM7.0 - 7` Counter Flow Aggregate Dryer / Drum Mixer

Portable or Stationary Units. 150 TPH to 225 TPH. Run up to 50% RAP (Recycled Asphalt Product). Slinger Feed Conveyor. Trunnion or Chain Drive. 1/2` Thick Shells. 3/8` Thick Adjustable Veiling Flights. Tarmac Combustion Flights Keep Material From Passing Through The Flame. Single Billet . Rolled Drum Tires. Welded Flex Plate Tire Supports, No Bolts to Come Loose. Large 1045 Steel Trunnions. Twin Thrust Rollers to Prevent the Drum from Walking Off The Trunnions. Hauck Long Nose Burners, Multi-Fuel (Gas, Oil, Propane). Primary and Baghouse Dust Entry

Model DM8.5 - 8.5` Counter Flow Aggregate Dryer/Drum Mixer

Portable or Stationary Units. 225 TPH to 300 TPH. Run up to 50% RAP (Recycled Asphalt Product). Slinger Feed Conveyor. Trunnion or Chain Drive. 1/2` Thick Shells. 3/8` Thick Adjustable Veiling Flights. Tarmac Combustion Flights Keep Material From Passing Through The Flame. Single Billet Rolled Drum Tires. Welded Flex Plate Tire Supports, No Bolts to Come Loose. Large 1045 Steel Trunnions. Twin Thrust Rollers to Prevent the Drum from Walking Off The Trunnions. Hauck Long Nose Burners, Multi-Fuel (Gas, Oil, Propane). Primary and Baghouse Dust Entry