Techflow Enterprises products

Techflow - Wear Resistant Bends

Bend Tuff ® from Techflow ® is specially designed wear resistant bends which allows a pneumatic conveying system to run for longer time without any maintenance shut down, breakage of material and jamming of material in conveying lines. Bend Tuff ® Can replace any ordinary or long radius bend with problem of wear and tear in line, these bend can give 20 times more life than usual bend. Wear Resistant Bends are designed for dense phase pneumatic conveying system and dilute phase conveying system where conveying pressures are very high.

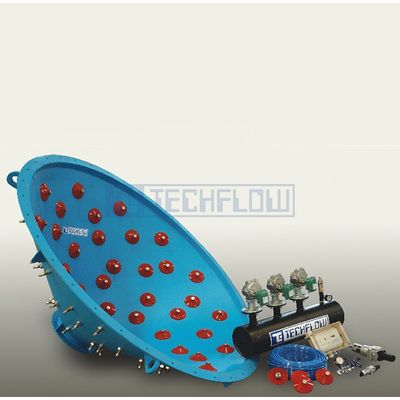

Techflow - Flow & Vibra Aeration Pad

Tuff ® - flow & vibra pads from Techflow ® are used as material discharge helping device in Silo or hoppers. It helps in getting uniform flow and discharge of dry bulk materials through minor vibration & aeration. It Prevents bridging, rat holing and compacting in storage silos, dust collectors, weigh bins and in other storage equipments. These pads are available in number of material to overcome the problems like high temperature, High abrasion & Food Grade.

Dust Collection (DE-Dusting) Systems

Pulse Jet - Dust Collector - Cartridge Filter

TECHFLOW is the Pioneer designer & manufacturer of Cartridge Type Pulse Jet Dust Collector (Pleated Bag Cartridge Filter) way back since 1980s in India. The Idea behind designing the Cartridge Type Filter was to save space and giving comparable result as a hose bag type filter. Cartridge type Pulse Jet Dust Collector / Cartridge Filter are basically used for applications with ambient temperature range and free flowing dust or materials. There are various dedusting filtration media available for different applications. These low height Dust Collectors are designed to operate continuously and with lowest down time. The timed pulses of compressed air travel in opposite direction of main airflow & by temporary reversal thro`cleaningblast via ventury,cartridge surface Is cleaned.

Pulse Jet - Bag Filter - Hose Bag Type Filter

Pulse Jet Bag Filter / Pulse Jet Hose Bag Type Filters are known as conventional dedusting filters. TECHFLOW has developed new age de-dusting designs for this filters which gives better life of filter bags, Lower emission levels, Lower Pressure drops, lower power consumption, Higher air to Cloth Ratios with better performance levels, Lower Floor Space Requirement. TECHFLOW supplies customized bag filters on the bases of application requirement. These Pulse Jet Bag Filters are used where air-flows are in large quantity, temperatures are higher than ambient or material to be handled is difficult.

Pulse Jet - Envelope Type Bag Filter – DE-dusting System

This de-dusting system is a special variant of horizontally mounted filter bag envelopes (pockets) over retaining metal cages. The advantage is low height & easy access to filter bags for maintenance & replacement. These dedusting systems are offered where there is a height constraint or front loading of filter elements are required. Cleaning of bags is achieved thro’ reverse compressed air timed pulses.

Techflow - Dust Collector - Mechanical Dust Collector

Cyclone dust collector is the the basic & most conventional mechanical way to separate the heavy dust particles from the air stream using centrifugal cyclonic/vortex effect due to tangential rotation. This can be used where particle size of the dust is heavy, as primary separator to reduce the dust load on the fabric filter or dust collector & as spark trapper in some application. TECHFLOW has developed a series of cyclone dust collectors where you can get maximum efficiency of dust separation with lower power consumption. This has resulted in better outlet emission, lesser load on bag filter or dust collection system, improving life of filter bags and better recovery of product.

Techflow - Dust Collection System - Mechanical Dust Collector

Multiclone dust collection system is second generation mechanical dust collector after cyclone. It is having multiple parallel cyclonic tubes inside the chamber which separates the heavy dust particles from the air stream using. This is used as primary separator to reduce the dust load on the bag filter or dust collector & also serves as primary spark trapper in some applications.

Fume Extraction and Filtration System

Techflow - Furnace Fume Extraction Systems

Techflow has got expertise on following applications of fume extraction and filteration. Many Industrial operations generate fumes during various processes like Furnace, Welding, Brazing, Cutting etc. These fumes are not only hazardous for Atmosphere but also harmful to Human life.

Techflow - Fume Extraction and Filtration System - Welding Fume Extraction Systems

From many industrial operations fumes can be generated during processing with Induction Furnace, AOD Furnace, EAF Furnace, SAW Welding, SMAW Welding, TIG Welding, MIG Welding, Brazing, Oil Quenching, Dipping, Boiler, Cupola Furnace, Gas Cutting, Robotic Welding, Spot Welding, Buffing, Grinding or any other process. This fumes creates discomfort for workers on shop floor and damages their health. As a leading manufacturer of Fume extraction system in India, TECHFLOW provides tailor made and user friendly Fume Extraction and Filtration system for different applications on the basis of requirement and site layout. TECHFLOW`s system can comply any emission related requirement of pollution control board in India & around the world. TECHFLOW also supplies hoods for extraction like motorized swivel hood, manual swivel hood, and other hoods as per requirement of application as a complete solution.

Techflow - Mobile Welding Fume Extraction Unit

In any Industry fume generation is bound to take place, it can be generated from any process like Induction Furnace, AOD Furnace, EAF Furnace, SAW Welding, SMAW Welding, TIG Welding, MIG Welding, Brazing, Oil Quenching, Dipping, Boiler, Cupola Furnace, Gas Cutting, Robotic Welding, Spot Welding, Buffing, Grinding or any other process. This fumes creates discomfort for workers on shop floor and damages their health. TECHFLOW provides tailor made and user friendly solutions for different applications on the basis of requirement and site layout. TECHFLOW`s system can comply any emission related requirement of pollution control board in India & around the world. TECHFLOW also supplies hoods for extraction like motorized swivel hood, manual swivel hood, and other hoods as per requirement of application as a complete solution.