Technical Manufacturing Corporation (TMC) products

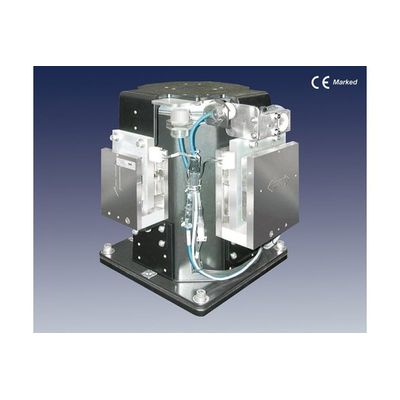

Piezoelectric Active Vibration Cancellation

STACIS - Advanced Active Vibration Cancellation System

STACIS III is the most advanced active vibration cancellation system. Employing advanced inertial vibration sensors, sophisticated control algorithms, and state-of-the-art piezoelectric actuators, STACIS cancels vibration in real time by continuously measuring floor activity, then expanding and contracting piezoelectric actuators to filter out floor motion.

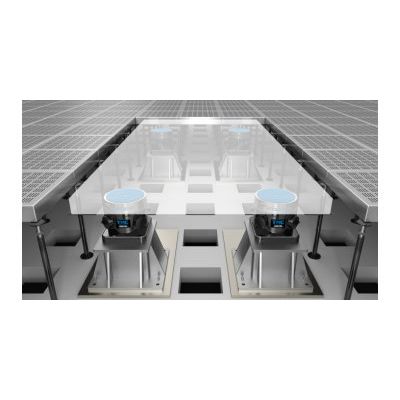

STACIS Quiet Island - Active Vibration Cancellation System

Semiconductor manufacturing factories (fabs), Nanotechnology Centers, Nanofabs, and other precision manufacturing and research facilities often incorporate cleanrooms with a system of raised false floors to accommodate complex facilities requirements (plumbing, electrical cables, gas piping, etc.) and to maintain strict cleanliness standards. Such floors present a challenge to the installation of vibration-sensitive production, inspection, and metrology equipment. The raised floors cannot provide the necessary quiet vibration environment for such tools. TMC`s Quiet Island is an innovative solution that replaces a section of the raised floor area with a "Quiet Island" anchored to the sub-floor below. The Quiet Island consists of a cleanroom compatible platform top combined with an application and site specific support structure.

STACIS - Floor Platform System

For conventional lab floors, isolating building floor vibration from large, tall tools presents an ergonomic challenge. Placing the isolators directly beneath the tool may raise the tool to an impractical height. Furthermore, conventional air isolators are unstable when placed close together under a tall, top-heavy payload. TMC`s STACIS Floor Platforms solve this dilemma. By combining our Stainless Steel Platforms with a unique "lifthood" design, our isolators "cradle" the platform allowing the tool to be lifted a minimal distance above the floor. And, because the isolators are not integrated into the platform, the platform may be custom designed to match the tool footprint or any desired shape.

Laboratory Tables

CleanBench - Vibration Isolation Table

CleanBench is the next generation of our industry standard 63 series lab tables. TMC`s vibration isolation lab tables lead the industry in performance and are ideal for a wide variety of applications including AFM, Confocal Microscopy, IVF, Patch-Clamping, Interferometry, and Metrology. CleanBench incorporates TMC`s unique Gimbal Piston Vibration Isolators and a tabletop with enhanced performance and features.

CleanBench - High Capacity Vibration Isolation Table

For table applications that require isolating over 350 lbs (160 kg) of net load, we recommend our High Capacity CleanBench 68-500 Series tables. They are similar in design to our 63-500 Series tables, with higher capacity isolators and a more massive stainless steel top plate. In addition to high load applications, the High Capacity CleanBench is also recommended for payloads with unusually high centers of gravity and equipment with moving stages. These applications should benefit from the increased stability. With a stiffer, more massive top plate, a lower natural frequency isolator, and stiffer, heavier leg frames, High Capacity CleanBenches provide performance that is markedly superior to any other passive table in the industry.

Optical Tables, Breadboards, Supports

TMC - Optical Tables and Isolation Systems

TMC`s optical tables and isolation systems offer industry-leading performance and rigidity thanks to an all-steel construction and the highest core density and smallest honeycomb cell area on the market.

TMC - Micro-g Optical Table Support Systems

Micro-g optical table support systems are an ideal match for our CleanTop optical tables and breadboards. A wide range of configuration options, including height, weight capacity, and vibration isolation performance, are available. Most tops are best supported by a 4-post system with tie-bars, however for those longer than 10 ft (3 m) we recommend a 6-post system. In addition to the higher weight capacity, the structural characteristics of the top are enhanced by the additional support points. When open access between the posts is necessary Micro-g Free-Standing Posts are a convenient alternative to posts with tiebars . Though generally configured in sets of 4 and 6 legs, other configurations include 3 and 5 legs. The independent posts offer the maximum flexibility in post positioning with respect to the optical top.

Active & Passive Vibration Isolators (OEM)

TMC Micro-g - Air Isolators for In-Tool Applications

TMC pneumatic vibration isolation systems are the solution of choice for tool designers seeking superior vibration isolation of ultra-precision instruments. TMC now offers our industry standard Gimbal Piston®, MaxDamp®, and UltraDamp™ isolators in a convenient range of capacities, damping levels and leveling versions to suit a wide-range of applications. Ideal for OEM applications, these isolators are offered in a modular, interchangeable, and upgradable design. And, to ensure you specify a version that will meet your settling time and isolation requirements, TMC engineers can model your configuration with our “Moving Stage Application Model.”

TMC Electro-Damp - Active Air Vibration Cancellation

Electro-Damp is the first commercial active vibration isolation system designed specifically to increase throughput, resolution, and yield in semiconductor manufacturing applications. The Electro-Damp II is a complete redesign of the original system, adding modularity, digital control, feedforward, high-force/high-clearance actuators, and multiple digital user interfaces specifically designed for use in OEM applications such as microlithography, inspection, and metrology tools.

TMC PEPS - Active Air Leveling System

PEPS II improves and builds upon TMC’s patented PEPS® (Precision Electronic Positioning System). With the addition of a new digital controller, PEPS® II is easier to use, offers more features, and has an improved user interface. PEPS® II is a digital non-contacting, height control system for TMC pneumatic vibration isolation systems. Such systems normally incorporate mechanical height valves and a mechanical height sensing linkage. Its applications range from semiconductor manufacturing equipment to improve settling time and increase yields, to precision laboratory environments which demand the optimum noise performance and platform stability.