TelePro, Inc. products

Spectrum Profile and Shape Model

Spectrum Systems Engineering (SSE) and TelePro, Inc., present a new rolling mill analysis and modeling software suite, the Spectrum Profile and Shape Model (SPS). This new product is an integrated package of proven mathematical models derived from the fundamental physics of the rolling process. These models are applicable to a wide variety of ferrous and non-ferrous, hot and cold flat rolling mills, accommodating both 4-high and 6-high roll stacks with roll bending and side-shifting variable crown work and/or intermediate rolls. Additionally, several commonly accepted mathematical models are included for the estimation of friction and material yield stress.

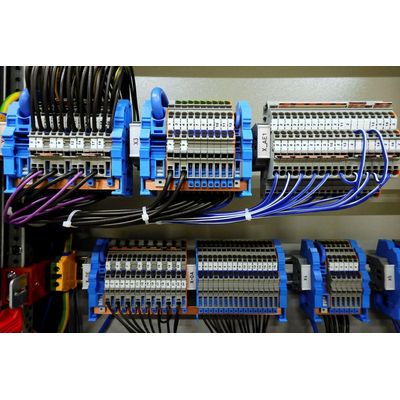

Rolling Mill Stand Controller

The TelePro/SSE hydraulic mill stand controller performs Level 1 device control of the hydraulic cylinders associated with work roll gap positioning, roll bending, and backup roll balancing in rolling mills. A mill stand state machine manages coordination and sequencing of the individual actuator systems, as well as transitions between operating states.

VEG/EE Gauge Control System

The gauge thickness variation of a rolled product is often considered one of the most important measures of the quality of the product. It is a measure of how closely the exit gauge tracks the desired nominal gauge as the sheet passes through the rolling mill. In practice, the largest contributors to excessive power in the gauge thickness variation are periodic disturbances occurring at frequencies higher than a typical feedback gauge control system is capable of tracking. Existing solutions to this problem come in two flavors. The first is to install an entry gauge and implement a feed forward gauge control system. However, this requires a large investment of several hundred thousand dollars in equipment and maintenance for an entry gauge.

Rolling Mill Automatic Flatness Control (AFC)

The TelePro/SSE AFC system consists of integrated control of work roll bending, HGC tilting, variable roll crown shifting (if available) and multi-zone work roll cooling to minimize deviations between target and measured exit strip stress distributions. The application software is implemented in the ANSI/ISO Standard C and C++ programming languages. The AFC functions are typically performed in the same PC-based computer system hardware used to implement the automatic gauge control (AGC), interstand tension control (ITC) and mill setup models. The following schematic diagram shows the overall layout of the AFC system for a 4-high mill with CVC work roll side shifting.

Automatic Gauge And Interstand Tension Control (AGC/ITC)

The TelePro/SSE AGC system consists of a basic delay-compensating feedback control algorithm requiring only exit thickness and main motor speed measurements. Enhanced mass flow and gaugemeter control loops requiring additional process measurements, as well as feedforward control, are also included. A stand-alone roll eccentricity compensation system is available as an option. The various components of the AGC system are all fully integrated. This means that bumpless transition mechanisms are provided for changing between modes while rolling (on manual demand or automatically, due to critical sensor failure). The ITC system for multi-stand mills consists of separate control modes for initial mill threading and steady-state rolling. The threading control mode is configured specifically to establish interstand tension during initial threading. The steady-state or run control mode is configured to reduce interactions between interstand tension and strip thickness.