THM Recycling Solutions GmbH products

Electrical / Electronic Waste

THM - Model TQZ - Turbo-Crusher

The original TQZ Turbo-Crusher is the state-of-the-art machine for recycling of fridges and electronic waste. Instead of cutting tools the TQZ uses movable chains for the crushing and breaking of the input material. The advantages of this innovative system are the separation of harmful components – without destroying the components - and the low cost of wear parts.

Cable Waste

THM - Model CM 100 - Cutting Mill

The THM CM Cutting Mill is the right choice for cutting of pre-size-reduced parts into smaller granules. Size reduction takes place by a wear resistance rotor with rotating knives which are cutting against stator knives. The final granule size is determined by the size of the screen holes. The granules are discharged pneumatically at a discharge trough with a discharge screw at the bottom of the machine.

THM - Model AG - Granulator with Bite

The extremely robust AG Granulator were develop for the size reduction of metals but does also perform very well when size reducing other material such as cable waste, plastics and other materials. No matter which type of material is fed into the AG Granulator – metal, recyclable waste or substitute fuels – the AG granulator performs brilliantly. All components are designed for a maximum durability. The rotor of the AG Granulator is manufactured out of rolled and forged steel and made for a demanding long term use even in the field of scrap metal recycling.

Refrigerators

THM - Model TQZ - Turbo Crusher

The original TQZ Turbo-Crusher is the state-of-the-art machine for recycling of fridges and electronic waste. Instead of cutting tools the TQZ uses movable chains for the crushing and breaking of the input material. The advantages of this innovative system are the separation of harmful components – without destroying the components - and the low cost of wear parts.

Tires

THM - Model CM - Cutting Mill

The THM CM Cutting Mill is the right choice for cutting of pre-size-reduced parts into smaller granules. Size reduction takes place by a wear resistance rotor with rotating knives which are cutting against stator knives. The final granule size is determined by the size of the screen holes. The granules are discharged pneumatically at a discharge trough with a discharge screw at the bottom of the machine.

Alternative Fuels

THM - Model XG 2400 - Universal Granulator

THM‘s Universal Granulator XG is used for single-stage shredding of a variety of different materials. Whether wood, RDF, cable scrap, electronic scrap, metals or other materials, the universal granulator XG performs brilliantly. Thanks to the large inlet opening, the Universal Granulator can shred very large and bulky . Parts to the desired final size in a single operation. A segmented granulating screen is mounted below the rotor. The hydraulically swing-off screen basket allows a quick and easy change of the screen segments. By selecting the screen-hole size, the output grain size is determined.

Other Products

THM - Model ZM - Granulator

The extremly robust ZM Granulator were develop for the size reduction of metals but doesalso perform very well when size reducing other materials such as cable waste, plastics and other materials. Nomatter which type of materiasl is fed into the ZM Granulator - metal, recyclable waste or substitutes fuels - the ZM granulator performs brilliantly. All components are designed for a maximum durability. The rotor of the ZM Granulator is manufactured out of rolled and forged steel and made for a demanding long term use even in the field of scrap metal recycling.

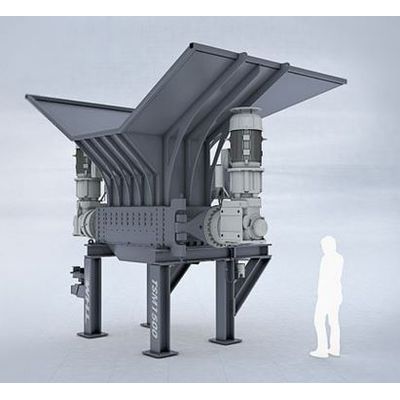

THM - Model TSM 1500 - Rotor Shear

Two-shaft rotor shear, designed for a long life cycle and easy maintenance. With its massive and screwed machine housing as well as the exchangeable knives, this shredder sets new standards in the crushing of metals, plastics, composites, rubber and much more. The machine offers added value through longevity, simple tool change and low maintenance times.

THM - Model ZM 300 - Small Granulator

Compact granulator with material feed funnel for shredding of metals, cable scrap, plastic waste and other materials. For small quantities in laboratory use, for sample preparation and analysis or for use with small throughput quantities. With its sturdy machine housing and design, the shredder offers additional value through durability and simple tool and screen changing.