ThyssenKrupp Uhde GmbH products

Pre-Reduction Plants

Mobile Crushing Plants

Mobile ThyssenKrupp crushing plants are in operation all around the world. It was ThyssenKrupp that pioneered mobile crushing plants, thereby making it possible to crush minerals directly at the site of extraction and synchronize to the rate of mining advance, into sizes ready for conveyor transport of the crushed material from the mining face to the processing plant.

Semi-Mobile Crushing Plants

Mobile crushing plants are built ready-mounted on their own travel gear. Semi-mobile plants, on the other hand, are moved from one location to the next as a piggyback load on separate haul units. Each crushing plant comes ready to operate with its own feed hopper, feed conveyor, discharge conveyor and material transfer belt. The size and design of the crusher naturally depends upon the work that it is intended for. Semi-mobile crushing plants are always to be recommended when a change of location in long periods is required in order to optimize the raw material transportation- and operational-costs of the quarry department.

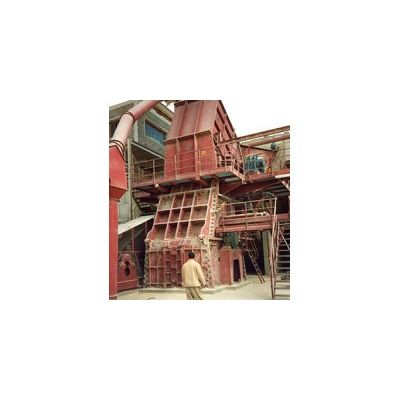

Stationary Crushing Plants

ThyssenKrupp builds and installs turnkey processing plants from stationary primary crusher plants right up to hardrock processing plants with all components. The planning of a completely new plant for the cement, lime and gypsum industries is performed by longtime experienced specialists. They determine the required process techniques, the design and the manufacture of the machines and components and then finally install, erect and commission the complete plant. That is the reason why ThyssenKrupp plants bring a maximum of performance while reducing the maintenance and operating costs to a minimum. In addition, ThyssenKrupp offers one of the widest ranges of strong, robust and proven standard machines and components, such as hammer crushers, impact crushers, double-roll crushers, gyratory crushers, jaw crushers, apron feeders, wobblers, vibrating feeders and vibrating screens.

Mammut - Single-Shaft Hammer Crusher

Uncomplicated and compact in design, rugged in its construction, extremely powerful and completely safe in operation and with a minimum maintenance requirement: Over the years, secured for itself a firm place in the cement, limestone and gypsum industry. The MAMMUT-crusher is fitted with a number of auxiliary devices which ensure that the main wearing parts can be removed and refitted very speedly and with minimum man-power.

Titan - Double-Shaft Hammer Crusher

The TITAN Double-Shaft Hammer Crusher is used for crushing medium-hard rock. For wet limestone, wet marl, clay, chalk, gypsum and similar raw materials. It permits a large feed size and is capable of producing a clearly defined finished product size being preselected by the gaps of the discharge grate and therefore able to produce fedd material for ball mills, high pressure grinding mills and vertical roller mills. This crusher distinguishes itself by its proved reliability and robust construction, ensuring a long service life. The feed material is continuously fed to the crusher. Large material blocks are first precrushed between the rotos. Subsequent reduction takes place on the anvil before the finished product is produced on the discharge grate. This mode of operation without fixed impact walls also permits the handling of comparatively moist and sticky material.

Impact Crushers

ThyssenKrupp impact crushers have an operating range which includes both coarse and fine crushing. They crush medium-hard to hard material. The ThyssenKrupp Impact Crusher produces a single stage perfect feed material for a vertical roller mill. ThyssenKrupp impact crushers are installed as stationary, semi-mobile or mobile crushing plants with plant capacities of more then 4,000 t/h.

Double-Roll-Crusher

Double-Roll-Crushers are used for the crushing or medium-hard rock as well as for sticky and soft materials, i.e. clay, marl, limestone and similar raw materials. Sticky and soft materials are reliably crushed in 2 or 3 stages down to the required product size. Due to the low crushing ration, the ThyssenKrupp Double-Roll-Crusher is producing a product size ditribution with less content of fines and therefore it is the most suitable machine for the lime-industrie.

RollSizer

The RollSizer are capable of crushing medium-hard rock as well as sticky and soft material such as coal, clay, marl, limestone and similar raw materials.

Gyratory Crusher

The design of the gyratory crushers and jaw gyratory crushers is based on more than one hundred years of experience. ThyssenKrupp gyratory crushers represent today‘s state-of-the-art. They are designed for high throughput rates and high crushing ratios at low operating and maintenance costs.

Kubria - Cone Crusher

Advanced technology means highest outputs, low operating cost, minimum maintenance, simple operation and maximum safety.