TKS Control Systems, Inc. products

TKS - Regenerative Thermal Oxidizers (RTO)

One of todays most widely accepted air pollution control technologies across the industry is Regenerative Thermal Oxidizer, commonly referred to as an RTO. RTO systems are used for VOC reduction, odor elimination, hazardous air pollutant (HAP) elimination, toxic air pollutant (TAP) elimination, opacity issues, and other requirements. A low initial capital cost, reduced annual operating cost, and minimal maintenance make this one of the most attractive technologies for our customers.TKS - Direct Fired Thermal Oxidizer

The TKS Direct Fired Thermal Oxidizers are often used when High VOC Concentrations exist in a given waste stream.TKS - Recuperative Thermal Oxidizers

The TKS Recuperative Thermal Oxidizers are often used when low to moderate levels of Hazardous Air Pollutants (HAPs) and Volatile Organic Compounds (VOCs) exist in a given waste stream. This air pollution control device combines the right levels of turbulence, oxygen, time, and temperature in order to reach the ideal thermal oxidation.TKS - Catalytic Oxidizers

Catalytic Oxidizers advance oxidation of VOCs to CO2 and water, permitting oxidation to happen at lower temperatures for thermal oxidation. Operating temperature, residence time, mixing of combustion air with waste gas, and catalyst traits are all important factors for catalytic oxidation. TKS Catalytic Oxidizer gets rid of Hazardous Air Pollutants and Volatile Organic Compounds that are released from many industrial processes.TKS - Rotor Concentrator Systems

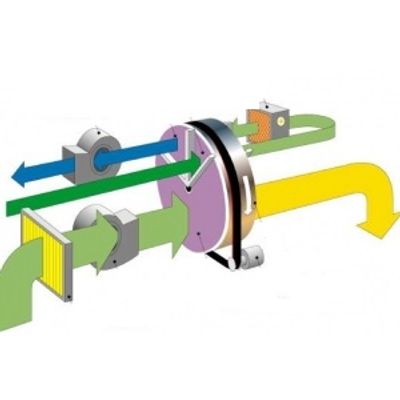

TKS Rotor Concentrator System destroys harmful emissions by thermal oxidation, while regenerating thermal energy to decrease the overall service cost and energy use. Rotor Concentrators have been widely used to paint booths, printing, solvent recovery, circuit boards, semiconductor applications and various other uses throughout the world. The real advantage of rotor concentrator technology is the large energy savings compared to other technologies. TKS supplies turn-key Rotor Concentrator Systems for your application.TKS - Acid Gas Scrubbers

Air Pollution Control Systems Custom Designed for Your Application. In order to counteract inorganic acids, TKS’s Acid Gas Scrubber efficiently scrubs numerous acids, such as hydrogen bromide, sulfur dioxide, and hydrogen chloride. These potentially threatening compounds are discharged from sources such as storage tank vents, boilers, and numerous chemical processes.

TKS - Air Filtration Systems

Air Pollution Control Systems Custom Designed for Your Application. Many applications require particulate removal before final clean-up with an abatement technology. TKS designs, engineers and manufactures many different types of dust collection systems for either stand-alone installation or integrated installation along with one of our thermal oxidizer technologies. Whether the best solution is cyclone, cartridge filter, or bag-house TKS supplies a turn-key installation for new or existing plant layout, fan selection, and supply of duct work installation, pneumatic piping, explosion vents, fire suppression, commissioning, 24/7 service, and after-market care.

TKS - Oven Systems

Air Pollution Control Systems Custom Designed for Your Application. TKS proudly designs and manufactures industrial ovens, specially modified for industry and government requirements. We customize each oven for the clients distinctive needs, taking into account temperature control accuracy, safety, material handling, capital cost versus operating expense, and numerous other variables to ensure a successful oven system.TKS - PTE Capture Systems

Air Pollution Control Systems Custom Designed for Your Application. TKS offers permanent total enclosures (PTE) as part of our pollution control systems. Regulations require volatile organic compounds (VOC) maintain an efficiency of 95% or better depending on your industry. Many applications require the use of capture hoods, floor sweeps and some PTEs to meet federal and state regulations. We have the experience and knowledge to design, build and install a complete system to comply with EPA method 204 requirements.