Tri Tool Inc. products

Tube Facing/Squaring

Tri Tool - Model STS-1 - Tube Squaring Machine

Pipe/Tube Size: 0.125" - 1.125" (3.2 mm - 28.6 mm). Wall Thickness: 0.125" (3.2 mm). Drive Options: 18V Electric: 115V Electric, 230V Electric, 100V Electric.

Tri Tool - - Model STS-1 - Tube Squaring Machine

Lightweight, portable facing machine designed for weld preparation on autogenous welding. Uses an OD saddle clamping system for material holding and an in-line feed collar. Can accommodate standard or short perch lengths for tube lengths less than .250".

End Prep Beveling

Tri Tool - Model Surefire 1.5 - Pipe Beveler for Boiler Maintenance

Tri Tool - Model Surefire 4 - Surefire Quick Change Pipe Beveler

Pipe facer/beveler featuring Surefire quick change mounting pads for clean, square weld preps on thin wall pipe and tube. The through hardened mandrel, solid milled body with a heavy-duty gear set, and tapered roller bearings ensure rigidity and reliability. The machine is light weight and has adjustable torque keys that prevent cutting vibrations producing smoother cuts.

Cutting & Beveling

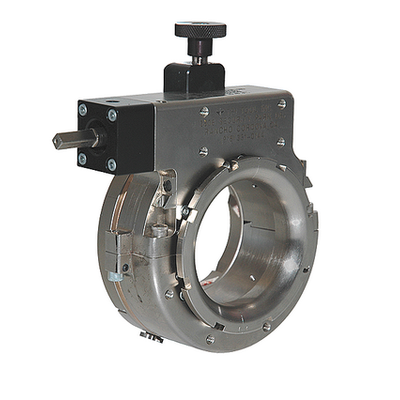

Tri Tool - Model 601SBCM - Split Frame Clamshell

These low profile clamshells are split-frame lathes that sever and bevel in-line tube and pipe. The lathes split into two halves and lock all moving components for secure ease of handling and mounting. The collet style clamping self-centers and does not distort the work piece. It can be configured for clean-room use (No Lead) and are protected by tough Nickel plating that makes them easy to clean and decontaminate.

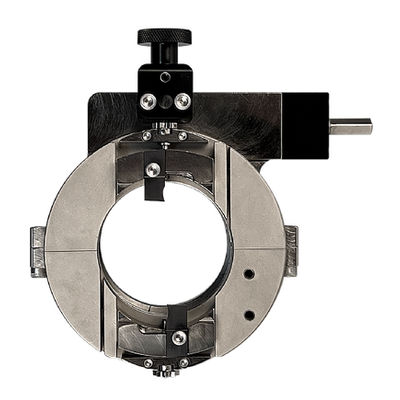

Tri Tool - Model 602SBCM - Split Frame Clamshell

These low profile clamshells are split-frame lathes that sever and bevel in-line tube and pipe. The lathes split into two halves and lock all moving components for secure ease of handling and mounting. The collet style clamping self-centers and does not distort the work piece. It can be configured for clean-room use (No Lead) and are protected by tough Nickel plating that makes them easy to clean and decontaminate.

Tube Severing

Tri Tool - Model PolySever 6 - PVDF and Polypropylene Pipe Cutter

The new PolySever 6 is the future of PVDF and polypropylene pipe cutting, delivering unmatched speed, safety, and efficiency. Designed for single-operator use, it cuts plastic pipes in under 90 seconds with no heavy labor required. Its compact, portable design makes it ideal for many cleanroom environments, while its advanced cutting technology eliminates micro-fracturing, ensuring perfect, crack-free results every time. With high precision and consistency, the new PolySever 6 reduces material waste and drastically lowers labor costs. Trusted across industries like semiconductor manufacturing, pharmaceuticals, HVAC, and water treatment, it sets a new standard for fast, reliable, and contamination-free pipe severing.

Tri Tool - Model 550CTC - Chipless Tube Cutting System

The Model 550 Chipless Tube Cutting System is a compact machine tool for rapidly and reliably severing tubes. This system is flight required hardware for many tactical US military aircraft and is used in civilian flight system maintenance roles as well.

Tri Tool - Model 572AC - Tube and Thin Wall Pipe Cutter

The Model 572AC SEVERMASTER severs .25” to 2″ (6.4 to 50.8mm) diameter tubes and thin wall pipe. This machine enhances productivity by incorporation of the auto-cycle tool model and quick lock collet closure. A cam cycle tool bit feed mechanism, with adjustable depth of feed from .001” to .005” (.02 to .13mm), automatically returns the tool bit to the home position ready to start the next cut. The feed increment per revolution is adjustable to optimize the cutting speed relative to the material. The tool module also allows setting the start and finish cut positions to minimize the cycle time. A variable speed motor provides further cutting speed control for increased tool bit life and ID burr reduction. The quick lock mechanism actuates the collet with a single lever stroke for simple collet changes.