Trimech Engineers Pvt Ltd products

Air & Gas

PSA Oxygen Plant

Atmospheric air contains 78 % of nitrogen & 21% of oxygen. Oxygen in PSA (Pressure Swing Adsorption) Method is generated by Physical separation of Nitrogen from atmospheric air and outlet the Oxygen is collected for use. The compressed air is passed through PSA Oxygen Tower which is interconnected with automatic changeover valves. In this Process, We can provide separate /Desiccant air Dryer. This has tendency of adsorbing moisture from compressed air. After that Dried compressed air will now come in contact with bed of Zeolite molecular sieves (ZMS). Zeolite Molecular Sieves are special grade of adsorbent which have the property of preferential adsorption of Nitrogen molecules. At a time one tower remains under Oxygen production cycle, whereas the other tower undergoes regeneration which is achieved through depressurization of the tower to atmospheric pressure.

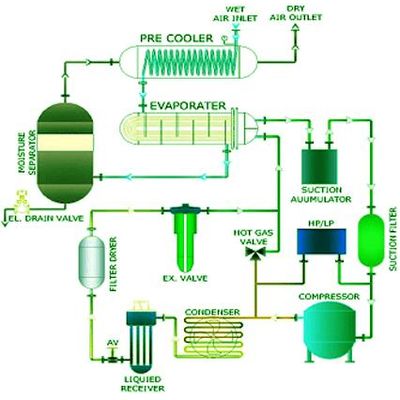

Refrigerator Dryer

The simplest way of removing moisture from compressed air is to reduce the temperature. In this TRIMECH dryer compressed air is passed through a heat interchanger where cold refrigerant at around 3 Deg C is passed through the other side of the heat interchanger. At this temperature most of the moisture is condensed which is then separated and drained out in

Air Polutions Control

Bag Filters

Industrialization is spreading rapidly and is necessary for the development of nation. On the other side, there is a threat to nature. Harmful emission in the air or water can damage the environment hence it is important to recover such toxic particulate matter from the exhaust gas. There are numerous ways to ensure that such pollutants are not released. Scrubbers, electrostatic precipitators, bag filters are some of the designs that retains particles and release clean air. Bag filters have been the choice for most of the industries these days. Bag filters have equally distributed 6 to 8 septa filters to avoid over expansion due to pressure. The filters are placed close to each other to ensure efficient filtration. The newer type of filters makes use of weaver of composite material to turn off the harm that may cause people. The static filter helps in efficient trapping of micro dust or minute particulate matter.

Dust Collector

Dust Collector is a vital part of any industrial operation and has been an important part of an industrial process since years. There are different types of industrial set up hence it is important to choose the type of dust collector that fits best to your need. Trimech India – dust collector manufacturer and supplier assists you to select one that can give your industrial process a maximum advantage. Dust collector manufacturer- Trimech India supports the making of its dust collector in a curetted design to fulfill needs as per industrial requirement without any inflated rates.

Cyclone Dust Collectors

Cyclone dust collectors are the simplest and least expensive dust collection devices for industrial Pollution control. As dust loaded air mixture enters the cyclone, it creates a vortex due to centrifugal action. A cyclone dust collector uses cyclonic separation to eliminate particulates air without the use of filters, during vortex separation. Rotational effects and gravity are used to divide mixtures of solids. Our series of Cyclone types dust collector used for set of heavier dust particles in various industries.

Material Handling Equipment

Bucket Elevator

Trimech bucket elevator systems are world-renowned for their quality and strength. Bucket elevators are built for complete life and moderate variety material handling purpose and with a list of remarkable features.

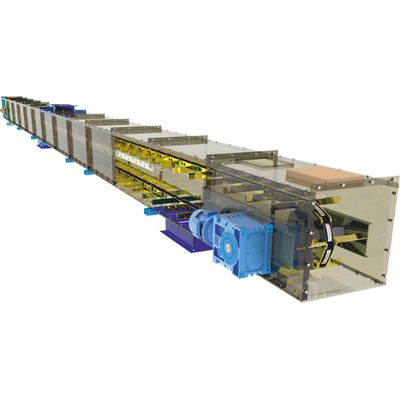

Belt Conveyor

Belt Conveyor is a one kind of mechanism that to transfer the material constantly. The belt works under the effect of frictional force. Belt conveyor are moving and carrying belts that ride on pulleys or rollers (two or more) that rotate around the belts and build a pull effect to drive the materials from one place to another. Today, they have become an indispensable tool in any material handling industry. They are also called conveyor belts. Their main aim is to carry any material or especially large materials in less time and without any workforce.

Drag Chain Conveyor

We provide our clients with a broad range of chain conveyors that is well known for its high load comportment capacity, robust construction and low maintenance. The Chain Type Conveyor is accessible in various sizes of width from 200 mm to 2000 mm width. Conveyors are one of the most widely held material handling systems. They use mechanized movement to transport material from its inlet to its discharge end through belts, chains, augers, buckets, etc. Drag Chain Conveyor Systems is also a well-established name in the list of conveyors.

Apron Feeder

Apron Feeder is for the prohibited volumetric feeding also blending volume materials. It is efficiently used for high blow and heavy load. Apron feeders are industrial machines that are used primarily to serve the purpose of material handling for materials that are of dry, frozen, sticky, or wet nature. These feeders are used for conveying heavy substances which usually involve coal, sugarcane, lime sand, and other kinds of materials. On dissecting an apron feeder, one can find that they consist of head-shaft, pans, tail-shaft, flights, and motors. The head and the tail shaft are covered by the metal chain wraps. Motors power the feeder providing large torque for its movement. Pans are used for extraction and for discharging the material from the feeder. The rollers are ridden using a combination of chain and flight. The apron feeder is installed under the end of the hopper. All these parts together make the apron feeder function.