Triple/S Dynamics, Inc. a KM Global Company products

Equipment - Vibratory Conveyors

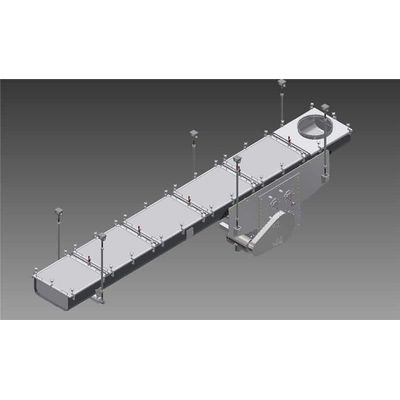

Triple S Dynamics - Sanitary Horizontal Motion Conveyor

The Slipstick Sanitary Conveyor, the first horizontal motion conveyor, is the food industry standard, recognized for its gentle, non-impact conveying motion and enviable record of low maintenance, high reliability and performance. Maintaining food safety and quality is the primary benefit of using the Slipstick in food processing applications. Unlike conventional vibrating conveyors that use a vertical pitching motion to propel material with repeated impacts which can cause the food to break or stick, the Slipstick’s single-drive mechanism provides a unique motion that glides the product down the pan, eliminating breakage problems for fragile foods such as chips, cookies, or cereal.

Triple S Dynamics - Industrial Vibratory Conveyor

Triple/S Dynamics pioneered horizontal motion conveying in the early 1970’s. The first units were sold into foundry and heavy metal operations. The Slipstick’s reliability in these harsh environments is unmatched. Some of the original 1970’s units are still in operation today. The Slipstick® Horizontal Motion Conveyor is recognized for its non-vibratory conveying motion and enviable record of low maintenance, high reliability performance. The slow forward-quick return motion is independent of natural frequency, springs and tuning.

Triple S Dynamics - Form / Function for Vibratory Conveyors

The key to horizontal motion conveying is the action of the conveyor upon the inertia of the conveyed materials. During the slow advance of the conveyor’s cycle, material is at a relative rest on the conveying surface. The quick return segment of the cycle gently slides the conveying surface under the material bed. Repeating this cycle 200 – 300 times per minute serves to smoothly convey the material up to forty feet per minute along the length of the conveying surface.

Equipment - Gates and Covers

Triple S Dynamics - Slide Gates

The Triple/S Eco-Slide Gate was developed when a major food processor approached Triple/S Dynamics with the problem of cleaning and maintaining the existing gates on their conveyors. They wanted the ability of the removal of the gate to be tool-less, less time for disassembly and reassembly during the sanitation process between plant production cycles. The Triple/S design team went to work to develop a new low cost gate system to meet the customer’s requirements.

Triple S Dynamics - Pivot Gate

The Pivot Gate offers maximum sealing security for minimal dust leakage without the use of an elastomeric seal in the product stream. The Pivot Gate uses spring loaded UHMW seals to press against the edges of a stainless steel gate plug that is flush fit in an opening in the conveyor pan bottom. The contact between the gate plug and the seal is a shear contact which wipes the contacting surfaces clean with each gate closing and prevents material buildup.

Triple S Dynamics - Plug Gate

The Plug Gate is designed to meet 3A Dairy Standards for maximum sanitation and protection of the product stream from contamination and features all welded stainless steel construction with no fasteners in the product stream. The Plug Gate is designed for quick disassembly for ease of cleaning and can be equipped with a removable white Nitrile seal to minimize dust leakage.

Triple S Dynamics - Covers

Dust-tight pan covers are available for just about every style of Slipstick conveyor. Covers may be flanged for connection to other equipment, interlocked for access restriction, and may be clamped and/or hinged for ease of sanitation maintenance. Pan cover sections are designed to be easily accessible by production staff and require no tools or special equipment for access or removal. Covers can be made of stainless steel, plexi-glass or a wide variety of other materials. Access ports and viewports may be specified. Stationary covers may also be employed with external supports.

Equipment - High-Speed Vibrating Screens

Triple S Dynamics - Inclined Vibrating Screen

Inclined screens are vibrated by a single, two-bearing, unbalanced rotor mounted concentrically or eccentrically with respect to the centroidal axis of the screen. Overhead-mounted rotors, designated “OHV”, generate a slightly rocking motion. The forward-inclined ellipse at the feed end accelerates incoming material to promote initial screening while the slightly backward-inclined ellipse at the discharge retards the oversize travel rate to help in the final removal of near-size particles.

Triple S Dynamics - Horizontal Vibrating Screen

Horizontal vibrating screens are available in the same sizes as the equivalent two-bearing inclined models. A pair of gear-coupled, parallel-shaft unbalanced rotors in an enclosed full-width vibrator module applies the straight-line inertia force that generates the receiptrocating motion of the screen box. The module is mounted so that its line of action passes through the center of gravity of the screen box, which moves in a straight-line, reciprocating pitching motion that conveys as it screens. This contrasts with the circular motion of the inclined screen, which depends on its downward slope to move the retained material over the screen.

Equipment - Texas Shaker Vibratory Screeners

Triple S Dynamics - Vibratory Screener

The Texas Shaker is designed for precision screening and sizing of dry granular materials in aperture ranges from approximately 1 ½” to 300 microns. Its long stroke, slow-speed horizontal reciprocating motion promotes rapid stratification, and constantly changing velocities yield the highest throughput of undersize per cycle. It is available in arrangements for 1-4 cutpoints in one machine.