Turner EnviroLogic, Inc. products

Thermal Oxidizers

Turner EnviroLogic - Direct Fired Thermal VOC Oxidizers (No Heat Recovery)

Turner EnviroLogic designs and manufactures direct fired thermal VOC oxidizers for applications with high VOC concentrations where the level of VOC`s themselves can support combustion without the use of fuel. Such applications include pipeline venting, tank venting, solvent cleaning station venting and chemical sterilization processes. Typically dilution air is added to supply the oxygen needed for combustion or to keep the thermal VOC oxidizer from running too hot during surges of high VOC concentrations.

Turner EnviroLogic - Regenerative Thermal Oxidizers (RTO)

For very low VOC concentrations, Turner EnviroLogic recommends a Regenerative Thermal Oxidizer (RTO) that is capable of up to 99% destruction efficiency and up to 95% heat recovery. A two-chamber, industrial RTO equipment is the most cost effective selection. Individual heat recovery chambers are filled with a ceramic heat sink media. Incoming VOC laden air enters one of the chambers where the gas is raised close to the light-off temperature by heat stored in the ceramic heat sink media. The heated gas is then burned in the top combustion chamber. These hot gases are then routed through a second chamber where the heat is again stored in the ceramic media. During the next operating cycle of the industrial RTO equipment, the gas flow though the unit is reversed by switching of a proprietary switching valve.

Turner EnviroLogic - Recuperative Thermal Oxidizers

Where the concentration of VOC`s is lower, auxiliary fuel is needed to maintain proper destruction temperatures. To minimize the amount of auxiliary fuel needed, Turner EnviroLogic applies a stainless steel heat exchanger to preheat the incoming gas with heat from the oxidizer exhaust. Recuperative thermal oxidizers can recover up to 70% of the of combustion heat. Significant energy savings result. Additionally, a precious metal catalyst can be employed to reduce the oxidation temperature to the 750° F range. With the use of this type of catalytic oxidizers, auxiliary fuel costs can be cut in half.

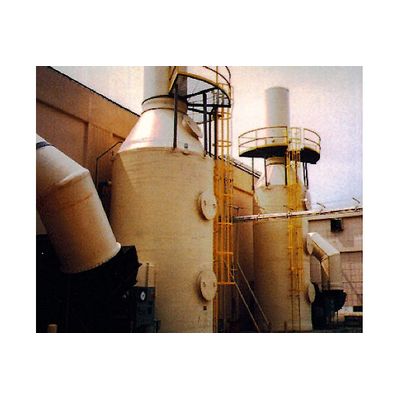

Wet Scrubbers

Turner EnviroLogic - Orifice Scrubber

The Orifice Scrubber is best suited for wet scrubber applications involving high dust loads with particulate size of 2 micron and larger. Removal efficiencies of up to 99% can be achieved. A high liquid-to-air ratio, and the ability to incorporate chemical addition, allows the Orifice Scrubber to be applied for acid removal and odor control applications also.

Turner EnviroLogic - Packed Bed Scrubber

Turner EnviroLogic Packed Bed Scrubbers are used to remove odors and fumes. They are also well suited to neutralize chlorinated and fluorinated gases such as Hydrochloric acid and Hydrogen Fluoride. Packed bed scrubbers are often used as a secondary system in conjunction with thermal oxidizers to remove acid gases that may form in the combustion process.

Turner EnviroLogic - Venturi Scrubber

High energy Venturi Scrubbers are used for the removal of course to very fine particulate. Even sticky and moist particulate can be collected easily. Removal efficiencies of 99.9% for particulate sizes down to 0.1 micron are achievable. Water sprays at the inlet of the Venturi can quench hot gases from processes such as casting, glass manufacturing, forging and incineration.

Selective Catalytic Reduction Systems (SCR`S)

Turner EnviroLogic - Model SCR - Selective Catalytic Reduction Systems

Today`s demand for turbine based peak power generation requires a generating plant that is highly reliable, is available on short notice and meets stringent noise and emissions standards. An integral component of any peaker unit is the Selective Catalytic Reduction (SCR) system utilizing specialized catalysts for the reduction of NOx and CO. Turner EnviroLogic`s SCR`s are proven, innovative, reliable and economical.

Continuous Emissions Monitoring System (CEMS)

Turner EnviroLogic - Continuous Emissions Monitoring System (CEMS)

Continuous Emission Monitors (“CEMs”) can play a vital part in an air pollution control system. Monitors are increasingly used either in an active role to control emission control systems, in a passive role to report or assure compliance, or in a combined role to fulfill both functions. Whatever the requirement, Turner EnviroLogic can provide a CEMs system to suit your needs. This system can either be a “stand alone” system, or can be integrated into the overall emission control system. Turner EnviroLogic has the knowledge, experience, and manufacturing capabilities

Engineered Exhaust Stacks

Turner EnviroLogic - Engineered Exhaust Stacks

Turner EnviroLogic designs, fabricates and erects exhaust stacks of all types. Each exhaust stack is designed in accordance with ASME STS-1 standards. Each application is carefully analyzed taking into consideration wind responses, temperatures and the corrosive effects of the gases exhausted. Sampling ports, platforms and ladders are standard features.

Industrial Dampers & Metal Expansion Joints

Turner EnviroLogic - Dilution Air Dampers

Dilution air dampers are applied to introduce fresh air into the inlet of thermal oxidizers and wet scrubber systems. Dilution air mixes with waste stream gases to cool or reduce the concentration of air pollutants