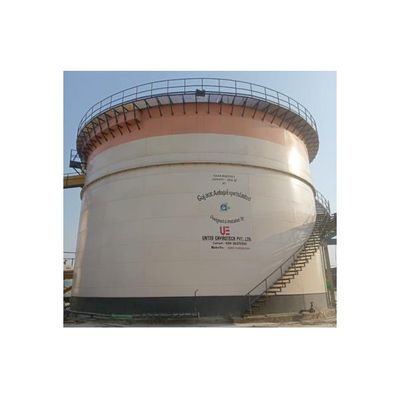

United Envirotech Pvt Ltd. products

Up-Flow Anaerobic Sludge Bio- Digester (UASB) Digester System

This treatment system is most widely applied for organic wastes / industrial wastes from distillery, starch, paper & pulp, dairy, tannery pharmaceuticals and other food processing industries. The Up-flow Anaerobic Sludge Bio- Digester (UASB) process is in operation for many years and has successfully demonstrated that waste water with high COD & BOD values can be treated with high efficiencies (upto 96%). ‘The waste water enters at the distribution network placed at the bottom of the Bio digester, this ensures the proper intermingling of the effluent with bacteria. The Biogas produced by the bacteria is in the form of small tiny bubbles rises upward through the bacterial bed. Methane rich Biogas is produced due to bio de-gradable property of the effluent which replaces fossil fuels.

United Low Retention Digester (ULRD) Process System

The Anaerobic Treatment of waste water is well established process which has wide range of application. This process is being used by most of the industries and more than 80% of the treatment is being undertaken through UASB type of digester. However, the anaerobic treatment of waste water with COD values ranging from 2000 to 130000 mg/l needs adequate retention time and area (foot print). At present the cost of owning land is becoming expensive day by day, this is true for existing or up-coming industries, Hence installation of ETP has been very challenging as the available area may be a constraint.

United Granular Sludge Bed Reactor

This is the advanced anaerobic treatment process. This will treat the organic effluents with a COD loading rate of 15 – 20 Kg/M3 volume of digester. It is the most suitable system for paper and pulp industry, Sugar industry, Breweries, Dairies, Petrochemicals and Other food processing industries. The internals of the systems are made from Polypropylene and it ensures corrosion proof Gas collecting system with no solid deposits on it, and this ensures the system`s life longer.

Fuel for Cars and Power Plants

Agricultural waste, manure, municipal garbage, plant matter, sewage, green waste, and food waste sugarcane press mud can all be broken down into Biogas without oxygen (Anaerobic Process). This mixture becomes bio-compressed natural gas after additional purification and processing. It is a cleaner alternative to fuels like gasoline and diesel and is similar to natural gas in terms of composition and quality. In India, bio-CNG has enormous potential, particularly as a substitute for the more popular CNG and liquefied petroleum gas (LPG or Liquefied Petroleum Gas). Bio-CNG can be a better substitute for CNG and LPG in hotels, households, automobiles, etc.

Condensate Polishing Unit (CPU) for Treating the Evaporation Condensate

Condensate polishing unit (CPU) for treating the evaporation condensate of raw spent wash evaporation plant and spentlees from distillery plant. The Condensate Polishing Unit (CPU) is part of the ETP which treats distillery effluent streams (Condensates) primarily MEE condensate. The effluent is passed through following respective units to reduce the pollutant load and make the resultant water fit for re-use in the process: It comprises of primary treatment of effluent followed by aeration as secondary treatment and tertiary treatment.

Zero Liquid Discharge

Zero Liquid discharge refers to installation of facilities and system which will enable any industrial effluent for absolute recycling of permeate and converting solute (dissolved organic and in-organic compounds/salts) into residue in the solid form by adopting method of concentration and thermal evaporation. ZLD will be recognized and certified based on two broad parameters that is, water consumption versus waste water re-used or recycled (permeate) and corresponding solids recovered (percent total dissolved / suspended solids in effluents).

Ejector and Jet Mixers System for Aeration Process System

The aeration tank being provided with air inlet, ejectors, liquid mixing jets, air blowers, recycle pumps, control system & interconnecting piping. The operation of the system is controlled by pneumatic actuators connected with PLC and DO transmitter. The aeration system after stabilization is operated for nitrogen removal also. Based on the DO present in the waste water the anoxic process being operated with help of liquid mixing jet nozzles.

Reverse Osmosis (RO) System for Effluent Recycle

The process of movement of solvent through a semipermeable membrane from the solution to the pure solvent by applying excess pressure on the solution side is called reverse osmosis.