Universal Aquacare Technology products

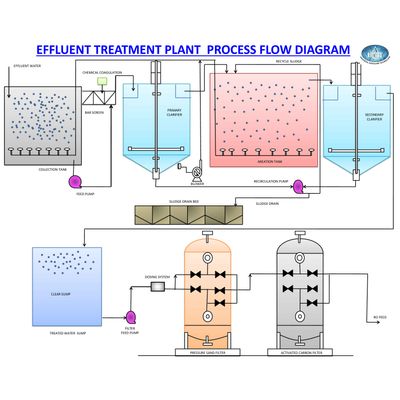

Effluent Treatment Plants

Effluent Treatment Plant or ETP is one type of waste water treatment method which is particularly designed to purify industrial waste water for its reuse and it’s aim is to release safe water to environment from the harmful effect caused by the effluent. Industrial effluents contain various materials, depending on the industry. Some effluents contain oils and grease, and some contain toxic materials (e.g., cyanide). Effluents from food and beverage factories contain degradable organic pollutants. Since industrial waste water contains a diversity of impurities and therefore specific treatment technology called ETP is required. The ETP Plant works at various levels and involves various physical, chemical, biological and membrane processes to treat waste water from different industrial sectors like chemicals, drugs, pharmaceutical, refineries, dairy, ready mix plants & textile etc.

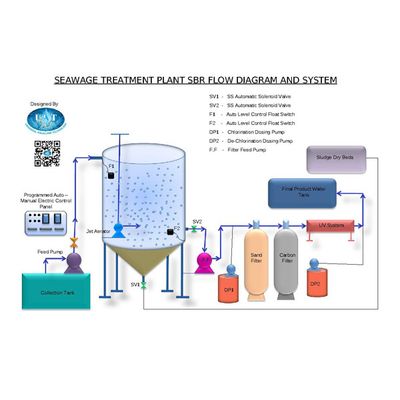

Sewage Water Treatment

Sewage treatment is the process of removing contaminants from wastewater and household sewage water. It includes physical, biological and sometimes chemical processes to remove pollutants. Its aim is to produce an environmentally safe sewage water, called effluent, and a solid waste, called sludge or biosolids, suitable for disposal or reuse. Reuse is often for agricultural purposes, but more recently, sludge is being used as a fuel source. Water from the mains, used by manufacturing, farming, houses (toilets, baths, showers, kitchens, sinks), hospitals, commercial and industrial sites, is reduced in quality as a result of the introduction of contaminating constituents. Organic wastes, suspended solids, bacteria, nitrates, and phosphates are pollutants that must be removed.

Zero Liquid Discharge Plants

1Zero-liquid discharge (ZLD) is a water treatment process in which all wastewater is purified and recycled; therefore, leaving zero discharge at the end of the treatment cycle. Zero liquid discharge is an advanced wastewater treatment method that includes ultrafiltration, reverse osmosis, evaporation/crystallization, and fractional electrodeionization.Aquatech has an unparalleled depth of experience in zero liquid discharge (ZLD), which include more than 160 installations, including stand-alone thermal/evaporative processes, membrane processes, or hybrid systems

Demineralization (DM) Plants

Demineralization is the process of removing mineral salts from Water by using the ion exchange process. Demineralised Water is Water completely free ( or almost ) of dissolved minerals as a result of one of the following processes : 1. Distillation, 2. Deionization, 3. Membrane filtration (reverse osmosis or nanofiltration), 4. Electrodyalisis, 5. Or other technologies. Demineralized Water also known as Deionized Water, Water that has had its mineral ions removed. Mineral ions such as cations of sodium, calcium, iron, copper, etc and anions such as chloride, sulphate, nitrate, etc are common ions present in Water. Deionization is a physical process which uses specially-manufactured ion exchange resins which provides ion exchange site for the replacement of the mineral salts in Water with Water forming H+ and OH- ions.

Demineralization (DM) Plants

Demineralization is the process of removing mineral salts from Water by using the ion exchange process. Demineralised Water is Water completely free ( or almost ) of dissolved minerals as a result of one of the following processes : 1. Distillation, 2. Deionization, 3. Membrane filtration (reverse osmosis or nanofiltration), 4. Electrodyalisis, 5. Or other technologies. Demineralized Water also known as Deionized Water, Water that has had its mineral ions removed. Mineral ions such as cations of sodium, calcium, iron, copper, etc and anions such as chloride, sulphate, nitrate, etc are common ions present in Water. Deionization is a physical process which uses specially-manufactured ion exchange resins which provides ion exchange site for the replacement of the mineral salts in Water with Water forming H+ and OH- ions.

Industrial RO Plants

The offered RO plants are designed to successfully handle demands of water filtration through utilizing following processes of purification:, , 1. Intake, 2. Pre-treatment, 3. High Pressure Pump, 4. Membrane Assembly, 5. pH Adjustment, 6. Disinfectio

Water Softener Plants

Natural water contains hardness producing compounds in different concentration. Our “AFI – Softener” are based on lon Exchange process to produce “Zero” hardness water. A hard water softener is an appliance that uses sodium chloride, also known as salt, to treat hard water. Hard water contains an excess of minerals such as calcium, magnesium, manganese, and iron that can be an expensive nuisance for a home. These minerals are taken up in the underground water supply and, as the water is heated in the home, they crystallize and stick to household surfaces. Sodium chloride, the effective component of water softener, works to replace these unwanted minerals.

Recycle & Reject Management

In industrial settings, RO is often used to remove total dissolved salts (TDS) from industrial wastewater or treated industrial wastewater and yield permeate with relatively low TDS concentrations. While RO is an effective method for handling wastewater, what to do with the concentrate or reject water (typically as much as 20-50% of the RO feed water volume) can be an issue. Specifically, the high salinity in RO reject / RO concentrate can make it prohibitive for discharge to a local sewer facility. Hauling the wastewater to a treatment facility can also be prohibitively expensive

Reverse Osmosis Plants [RO-Plant]

Reverse Osmosis [RO] is the process of forcing a solvent from a region of high solute concentration through a membrane to a region of low solute concentration by applying a pressure in excess of the osmotic pressure. This is the reverse of the normal osmosis process, which is the natural movement of solvent from an area of low solute concentration, through a membrane, to an area of high solute concentration when no external pressure is applied. The membrane here is semipermeable, meaning it allows the passage of solvent but not of solute. To illustrate, imagine a semi permeable membrane with fresh water on one side and a concentrated aqueous solution on the other side. If normal osmosis takes place, the fresh water will cross the membrane to dilute the concentrated solution. In reverse osmosis, pressure is exerted on the side with the concentrated solution to force the water molecules across the membrane to the fresh water side.

Mineral Water Treatment Plants

Universal Aquacare`s Mineral Water / Bottled water packaging equipment has a wide range of variants which meet our clients specific requirements of Rinsing filling capping bottles of various sizes. The Equipment is a fully automatic consisting of In-Feed air conveyor followed by rinser filler capper which Rinses, fills and caps and finally a discharge conveyor. The PET bottles are automatically Rinsed filled and capped untouched by human hand. The bottles automatically transfer to the discharge conveyor where they can be labeled and Batch Coded before being put inside cartons (or) packed in shrinks film. Our company has emerged as a leading and reliable manufacturer and supplier in the field of Mineral Water Treatment Plant.