Ventilatorenfabrik Oelde GmbH products

Dust Collection and Process Air Cleaning Plants

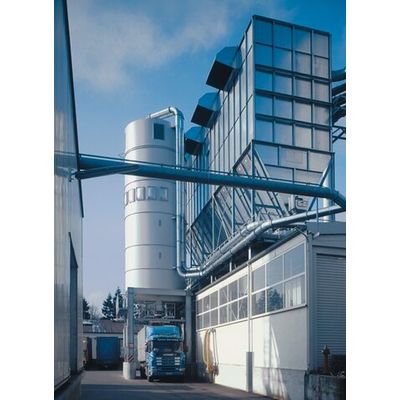

Venti Oelde - Process Air Cleaning Plant

Switch off the contaminants, switch on to efficiency. For complex applications when cleaning process gases, Venti Oelde offers very practical solutions. They are functional, reliable and have a long life. They are efficient and cost-effective. For process gas-cleaning systems, dry sorption processes upstream of the filter systems are becoming increasingly important. By using various absorbants/adsorbants we can remove foreign materials from air and can neutralise acid contaminants. A recirculating system makes optimum use of these additives.

Venti Oelde - Jet Bag Filter

Special separation systems are required for very fine dust. The same is true for fibrous, sticky or moist dust, or for dust which is difficult to agglomerate. Processes with a high concentration of dust and material require filter systems which continue to work reliably when the filter surfaces are subject to maximum loading. Venti Oelde filters do everything you would expect of a modern filter system. Venti Oelde offers a single or double row filter, depending upon the amount of air, the amount of dust it carries and upon the space available. All filters can be used as suction and as pressure filters. The double row designs are arranged with a centrally located inlet corridor for the unfiltered gas.

Venti Oelde - Oval Bag Filter

The ROVAL, oval bag filter range is a compact, space-saving and extremely efficient bag filter system for the separation of almost all dry, free-flowing dusts. The oval filter bags are installed horizontally in the dust-laden gas plenum. They are clamped and sealed against the slotted wall from the clean air side. The advantage of oval filter bags is that they keep their shape. Cleaning is supported by the vertical downflow to the bags. Short, powerful pressure pulses dislodge the dust cake from the filter surface. The pulses come from the compressed air tanks, via the propulsion jet pipes into the oval filter bags.

Venti Oelde - Round and Cyclone Filters

To separate large quantities of bulk materials, our robust and low-maintenance round filters with integrated cyclone separators are tried and tested. Amongst other things, they are used as final separators for pneumatic conveying systems. Venti Oelde makes round and cyclone filters tailored to your requirements. Depending on the application, we use a variety of sheet thicknesses and materials such as stainless steel and highly wear-resistant steel. We offer filters in a variety of versions, such as those that fit on top of bunkers, with a filtered air dome or with a swivel lid.

Venti Oelde - Reverse Air Filters

When filtering air containing bulky and/or fluffy fibrous material, other parameters apply than for conventional dust. The aim is to avoid dust collecting in the spaces between the filter bags to ensure a continuous discharge of the filtered dust as well as to maintain a constant pressure loss in the filter. Venti Oelde has developed special reverse air and pulse filters for the processing of light-density materials in the wood, fibre, textile and paper industries. They work with air volumes from 10,000 m³ up to in excess of 250,000 m³ per hour and at maximum temperatures of 60°C. They guarantee trouble-free, continuous operation and can be supplied to conform to the ATEX 94/9/EU guidelines.