Ventilatorenfabrik Oelde GmbH products

Industrial Fans

Venti Oelde - Large and Special Fans

Large and special fans from Venti Oelde are used in almost all key industries. They are the “heart” of industrial plants and processes, as they are mostly in use around the clock, for example in the cement and steel industries as well as in the chemical industry and refining plants, in power stations and waste incineration plants. Other areas of application are the mining, food, glass and woodworking industries, to name just a few.

Venti Oelde - Material Transport Fans

Material transport fans are mostly used in the wood industry, but solid particles are also pneumatically transported in many other industrial applications. Even when the requirements are extreme, our material transport fans ensure that material flows reliably.

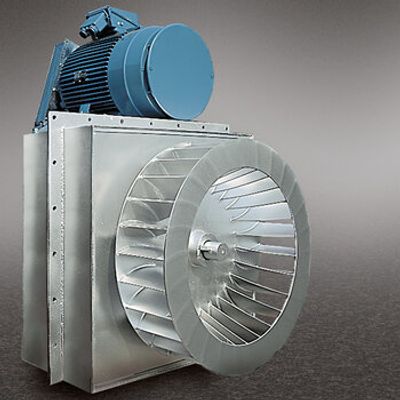

Venti Oelde - High-Pressure Fans

Venti high-pressure fans combine intelligent technology with outstanding quality. Venti high-pressure fans can be used in almost limitless ways, but especially as pressure-increase fans in industrial processing and chemical engineering, for the fluidisation of powders, dusts and granulates in the cement, paint and plastics industry, as forced-draft fans for firing plants, as combustion air fans in industrial furnaces, glass-melting pans and smelting plants. Our high-pressure fans work over pressure ranges from 30 to 250 mbar.

Venti Oelde - Hot Gas Circulation Fans

Our circulating fans can withstand temperatures of up to 1,000°C and are used for tempering, annealing and hardening furnaces, as well as for core drying. To operate the furnace system economically an even and fast exchange of heat is required. The air cooling system used by Venti Oelde has proved itself again and again under the toughest conditions. The Venti Oelde Duplo shaft cooling system prevents the transfer of heat from the furnace through the shaft to the particularly sensitive roller bearings.

Venti Oelde - Tearing Fans

The processing of excess continuous material. With tearing fans, we can shred continuous material such as edge strips which arise, for instance, during the manufacture of paper, cardboard and fibreboards. The fan’s design is dependent on the width of the edge strips, the roll-off speed and the type and thickness of the material. The tensile strength and coating of the waste are also determined and used in the calculations. The impeller blades are fitted with replaceable cutters or saw-strips, with which the continuous strips are shredded.