Veolia Water Technologies products

Solutions - Technologies - Water Treatment Technologies

Veolia Actiflo - Compact Water Clarification Process System

Actiflo® is ideal for drinking water and is particularly efficient in treating algal bloom, removing phosphorus and reducing the taste and odor associated with algae. There are more than 1,100 Actiflo references all over the world featuring more than 1,800 units, including more than 900 package plants, in municipal and industrial water and wastewater applications. The technology is also suitable for utility feed water, water reuse applications and to manage stormwater.

Veolia Actina - Drinking Water Softening Process System

Actina™ - Pellet softening providing the users’ comfort. Actina™ is a drinking water softening process by pellet softening designed to limit calcium carbonate deposits. Actina™ is a drinking water softening process by pellet softening designed to limit calcium carbonate deposits caused by a daily use of hard water on dishes, shower systems or in the pipes. These deposits can cause clogging and affect the proper operation of household appliances and water heaters. By reducing the calcium hardness at the earliest stage possible, Actina™enables Municipalities and Industries to access softened water peacefully, and to dispense with additional softening in private property or in their factories.

Veolia Anita Mox - Sustainable Deammonification Anammox Process System

Anita™ Mox, Veolia Water Technologies anammox process, is a cost-effective and sustainable solution for the treatment of streams highly loaded in ammonia, such as municipal effluents from anaerobic sludge digestion, drying condensates, industrial wastewaters and landfill leachates. Compared to conventional nitrification-denitrification processes, the Anita Mox process achieves an ammonia removal efficiency of over 90% with no use of external carbon source and at a very low energy cost, thus making it the ideal solution to reduce operating cost and improve the environmental record of a wastewater treatment plant. Anita™ Mox is a cost-effective and sustainable deammonification solution for the treatment of streams highly loaded in ammonia.

Veolia AnoxKaldnes - Moving Bed Biofilm Reactor (MBBR)

The Moving Bed Biofilm Reactor (MBBR) solution is a biological wastewater treatment and biological water treatment processes where biofilm grows on carriers suspended in wastewater that removes pollutants in a cost-efficient way. It can be used across almost all municipal and industrial market sectors. Moving bed biofilm reactor for cost-efficient removal of pollutants from municipal and industrial wastewater. High efficiency for BOD, ammonia and nitrogen removal.

Veolia Barrel - Multi Reverse-Osmosis (RO) Or Nanofiltration (NF) Pressure Vessel

The Barrel is a multi reverse-osmosis (RO) or nanofiltration (NF) pressure vessel that is designed to be a plug-and-play system. It ensures the fresh water produced meets all desalinated water quality standards for both municipal and industrial markets. It is also suitable for wastewater reuse and low pressure RO applications. Its modular design makes it highly scalable, offering varying capacities from 400 to 50,000 cubic meters a day per unit.

Hydra-Stat - Polymer Activation Sensor

Polymer Activation Validation System and Optimization Software. Benefits for the Operator: Prevents process downtime (pro-active tool). Allow operator to visualize and confirm polymer activation. Compare polymer activation levels (better selection of polymer). Reduces polymer consumption by optimizing mixing time and batch size (saves money) and can prevent polymer degradation.

PURELABFlex - Pure and Ultrapure Laboratory Water From a Single System

ELGA has been a trusted name in water purification for over 50 years, pioneering innovative technologies and award winning product design for our customers. Part of the world’s leading water services company Veolia Water Solutions and Technologies, ELGA have the most comprehensive range of water purification systems available today for laboratory research, healthcare and diagnostics. Water is the most common reagent used in today’s laboratories for research and testing applications and we understand how important accurate consistent test results are. The PURELAB flex range is designed around your needs, delivering accuracy, flexibility and ease of use with an innovative and ergonomic design.

HydraPol-N - Neat Polymer Systems

Veolia’s liquid polymer systems are designed to process and deliver the full range of HMW (high-molecular-weight) polymers in the emulsion, dispersion and solution form. The unique four-step process is controlled by the patented, pressure regulated hydraulic mixing circuit. Liquid polymer and water combine through the four processing stages of premixing, blending, recycling and control to invert, disperse and condition the polymer. This imparts maximum activity development in the dilute aqueous solution phase. The entire process design applies proven physical-chemical principles of kinetic acceleration, polymer dispersion, viscosity equalization, pressure equilibrium and polymer structuring. The result is optimal polymer conditioning.

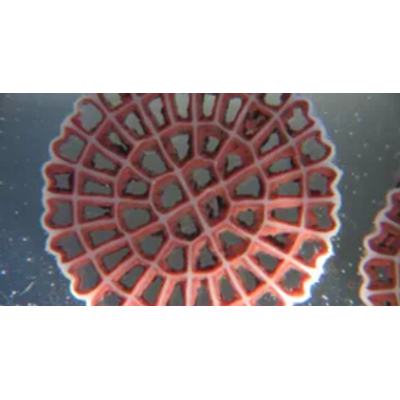

AnoxKaldnes - MBBR Activated Sludges and Other Biofilm Systems

The patented MBBR process is based on the biofilm principle and utilizes the advantages of activated sludges and other biofilm systems without being restrained by their disadvantages. The core of the process is the biofilm carrier elements that are made from polyethylene with a density slightly below that of water. The elements are designed to provide a large protected surface area for the biofilm and optimal conditions for the bacteria culture when the elements are suspended in water. AnoxKaldnes developed carriers of different shapes and sizes which gives us the flexibility to use the best suitable carrier depending on wastewater characteristics, pre-treatment, discharge standards and available volumes.

AnoxKaldnes - MBBR Water Treatment Technologies

Solutions based on AnoxKaldnes MBBR technology offer numerous benefits, such as robust biofilm, flexible reactor design, easy upgrade of existing plants, easy to operate and control, no sludge return needed in most applications, low load on particle separation stage.