VIEW Micro Metrology products

Micro Metrology Systems - Optical Metrology Systems

VIEW Metrology System - Model Summit 600/625/800 - Large Area High-Accuracy Dimensional Measurement Systems

The VIEW Summit systems are designed for components requiring a large work envelope and high accuracy. Based on the same core technologies of optics, high speed linear motors, and high resolution scales used in the VIEW Pinnacle, the Summit features a fixed bridge design. Separate X and Y axis motion systems ensure that neither influences the mechanical integrity of the other, while also enabling easy loading and unloading of large parts.

VIEW Metrology System - Model Pinnacle 250 - High-Speed, High-Accuracy Dimensional Measurement

The Pinnacle 250 offers the highest accuracy and fastest speeds of the VIEW line. Its high performance and compact footprint make it VIEW’s most popular model. The Pinnacle features a damped granite base and column, with passive vibration isolation. A precision compound X-Y stage with high-speed linear motor drives provides velocity of 400 mm / sec and acceleration of 1000 mm / sec2. This combination of high acceleration and high velocity enables the high throughput required for near-line process monitoring. The rugged and compact design of the Pinnacle lends itself to installation in either a Q/A lab or at an inspection station in the manufacturing line.

VIEW Metrology System - Model Pinnacle Plus - Ultra-High Accuracy Dimensional Measurement

Pinnacle Plus elevates Pinnacle performance to the next level. Pinnacle+ Plus features a rigid granite optical support structure and a high performance Z-axis motion assembly to produce the lowest possible uncertainty on micro-electronic parts and assemblies/ State-of-the-art linear motion control technology provides the fastest, most reliable platform available for high capacity operation in production environments ranging from clean rooms to factory floors.

VIEW Metrology System - Model Benchmark 250 - Compact High Accuracy Dimensional Measurement

The VIEW Benchmark 250 is engineered for high accuracy in a compact benchtop configuration complete with VIEW`s dual magnification optics and metrology-grade construction. The Benchmark 250 is designed for use on the production floor to provide precision measurements for process control. Its compact size and powerful software make the Benchmark 250 a versatile measurement system that can be easily configured as either a dedicated gauge for critical dimension measurements or as a general purpose vision measurement system for routine quality monitoring. Benchmark 250 and VIEW metrology systems are ideal for measuring flat 2D parts with very tight tolerances. Ideal industry applications include semiconductors, microelectronics, aerospace, medical devices, small machined parts, and other parts requiring automated non-contact measurement.

VIEW Metrology System - Model Benchmark 450 - High-Value High-Accuracy Dimensional Measurement

The VIEW Benchmark 450 delivers high performance with generous measuring envelopes. The system’s stage handles large form-factor parts with high precision in a rugged, shop-floor configuration with a small footprint. Its fixed bridge design separates the X and Y axis motions, allowing each to operate without any influence on the other. This arrangement provides the maximum mechanical integrity and accuracy in the stage motion. Benchmark 450 and VIEW metrology systems are ideal for measuring flat 2D parts with very tight tolerances. Ideal industry applications include semiconductors, microelectronics, aerospace, medical devices, small machined parts, and other parts requiring automated non-contact measurement.

VIEW Metrology System - Model Precis 200 - Ultra High Accuracy Critical Dimensional Measurement

VIEW Precis combines the XYZ accuracy of VIEW systems with ultra-high magnification optics. Precis features a microscope objective turret and a high performance Z-axis motion assembly to provide the best possible optical focus at extreme magnifications. The most accurate XY stage VIEW has to offer combined with the versatile yet powerful objective turret creates a metrology machine for the most demanding applications.

VIEW Metrology System - Model Summit 600 - Large Area High-Accuracy Dimensional Measurement

VIEW Summit systems are designed for components requiring a large work envelope and high accuracy. Based on core technologies of high-end optics, high-speed linear motors, and high-resolution scales, the Summit 600 features a fixed bridge design. Separate X and Y axis motion systems ensure that neither influences the mechanical integrity of the other, while also enabling easy loading and unloading of large parts.Proprietary Technologies

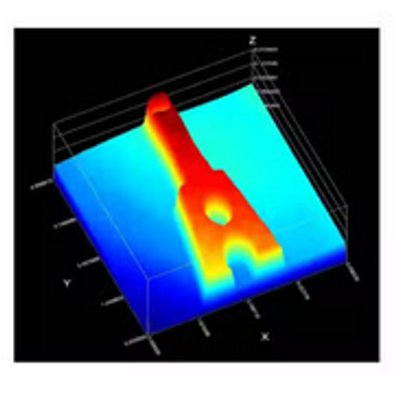

VIEW Software Feature - Area Multi-Focus (AMF) Technology for 3D Surface Measurement

AMF™ is an advanced video analysis technique available on VIEW Micro Metrology Summit, Pinnacle, Benchmark, and Precis dimensional measurement systems. The feature uses the data collected from a normal video auto-focus step and turns it into a 3D image of a feature. In addition to 3D information, it provides height or depth measurement of multiple features of a single image. This technique can be used to measure flatness, roughness, height, and volume. It is faster than any scanning method requiring XY stage motion.VIEW Software Feature - Continuous Image Capture (CIC) Technology

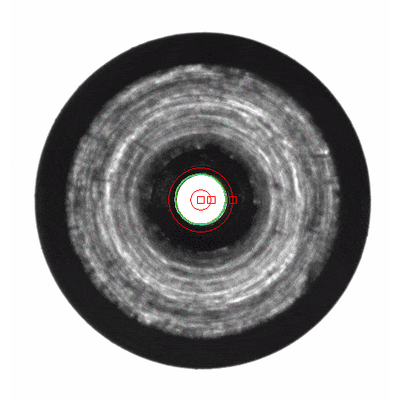

VIEW System Feature - Digital Megapixel Cameras

Available digital megapixel cameras offer significant advantages for precision metrology. The larger pixel array provides a larger field of view, while greater pixel density provides higher resolution. A larger field of view can improve throughput by capturing more part information with less stage motion. High pixel density improves accuracy and repeatability at a given magnification.