VIEW Micro Metrology products

Proprietary Technologies

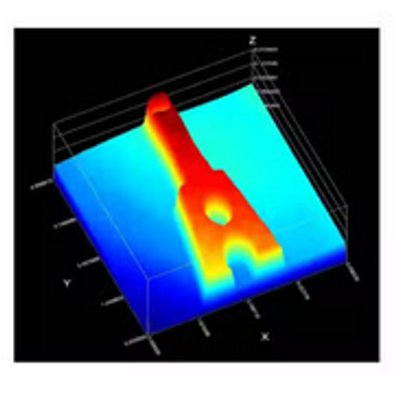

VIEW Software Feature - Area Multi-Focus (AMF) Technology for 3D Surface Measurement

AMF™ is an advanced video analysis technique available on VIEW Micro Metrology Summit, Pinnacle, Benchmark, and Precis dimensional measurement systems. The feature uses the data collected from a normal video auto-focus step and turns it into a 3D image of a feature. In addition to 3D information, it provides height or depth measurement of multiple features of a single image. This technique can be used to measure flatness, roughness, height, and volume. It is faster than any scanning method requiring XY stage motion.VIEW Software Feature - Continuous Image Capture (CIC) Technology

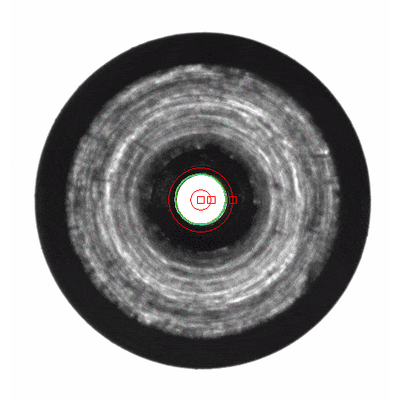

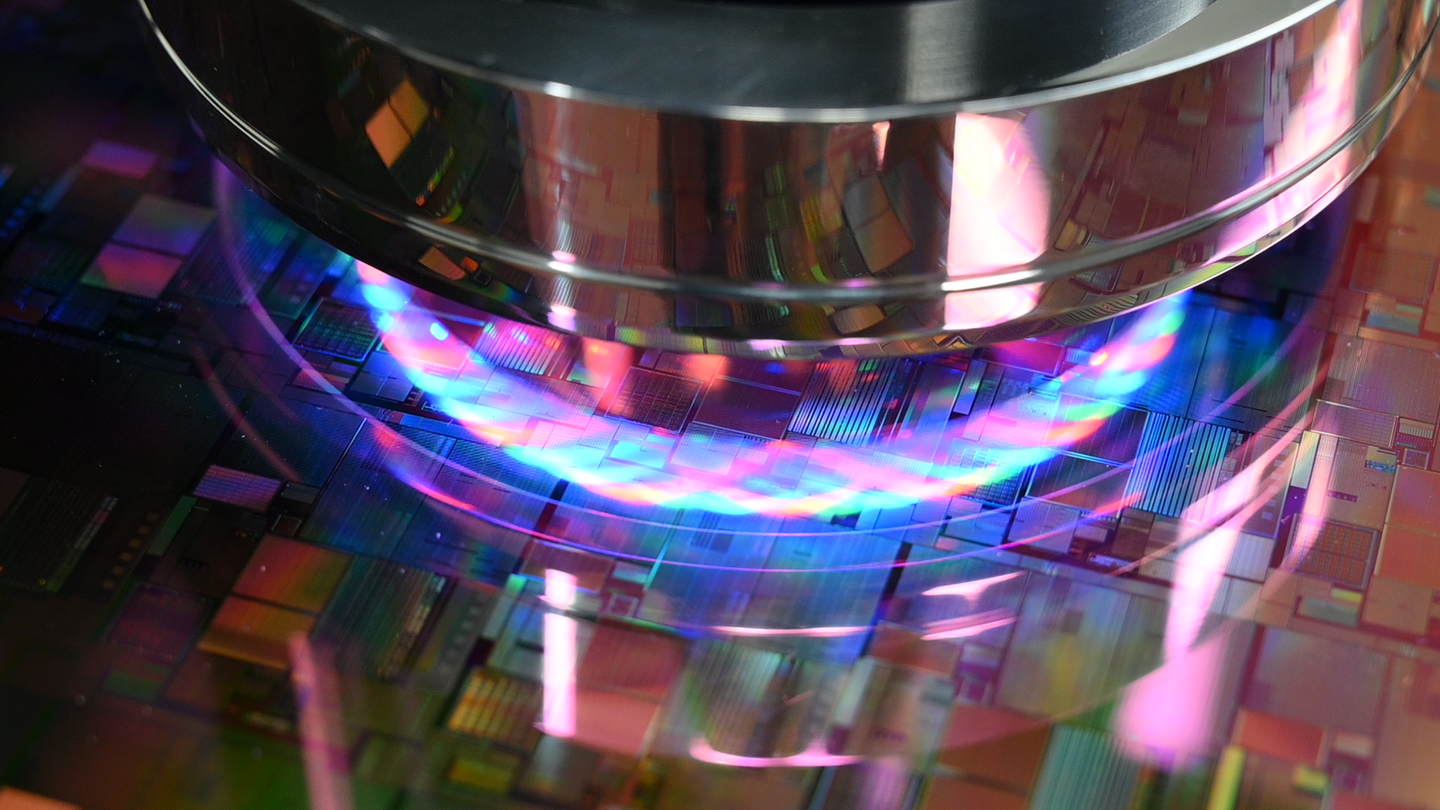

VIEW System Feature - Digital Megapixel Cameras

Available digital megapixel cameras offer significant advantages for precision metrology. The larger pixel array provides a larger field of view, while greater pixel density provides higher resolution. A larger field of view can improve throughput by capturing more part information with less stage motion. High pixel density improves accuracy and repeatability at a given magnification.

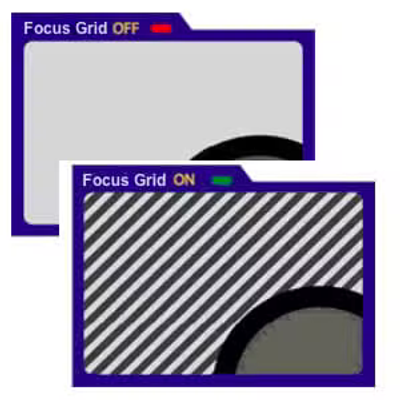

VIEW System Feature - Focus Camera Grid Projection Illuminator

The Focus Grid illuminator system is designed for situations where there is little or no surface texture visible to the camera, making traditional autofocus difficult. The system projects a grid of lines onto the part surface and measures the sharpness of the grid image to determine the optimum focus.

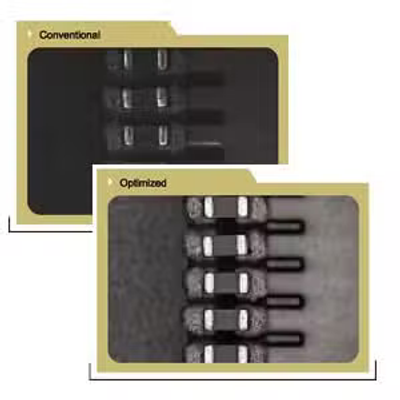

VIEW System Feature - High Brightness LED Illuminators

All VIEW systems are equipped with high brightness LED illuminators. LEDs offer long life, low power consumption and cool operation. In addition, LEDs allow the color temperature of the illumination to be closely controlled. Back-light and through-the-lens surface light are standard on all machines. During programming and automatic measurements, the light source and intensity for each measurement may be programmed to best illuminate the feature of interest. For surface features that are at an angle with respect to the X-Y plane, VIEW’s Programmable Ring Light (PRL) may be used.

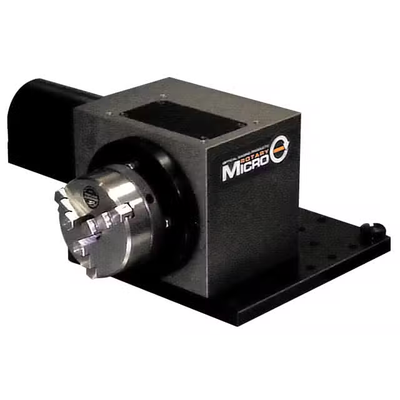

VIEW Sensor Options - Model MicroTheta - Rotary Indexer System

The MicroTheta™ Rotary indexer adds 4th axis capability to any VIEW video system equipped with VMS. With MTR, parts can be automatically rotated within a measurement routine to present a different view to the system. This enables VMS to inspect a surface of a part, index the rotary to a different location, and then inspect another surface of the part. With the power and flexibility of VMS, the user can inspect features on a greater number of surfaces on 3D parts.

VIEW System Features - Single and Dual Magnification Optics System

VIEW systems offer a choice of optical systems to best suit the measurement application at hand. VIEW Benchmark, Pinnacle and Summit systems may be configured with either the Single Magnification Fixed Lens Optics, or the unique Dual Magnification Optics system. Both of these arrangements offer optical interchangeable front objective lenses to allow the magnification and field of view size to be matched to the features being measured.