- Home

- Companies

- Vortex Hydra S.r.l.

- Products

Vortex Hydra S.r.l. products

Machinery - Uno Twin Starter Pack

Vortex - Model UNO 5 - Twin Starter Pack Plant

This is a Vortex Entry Level plant consisting of a robustly constructed machine that ensures the production of high quality concrete roof tiles. The aluminum pallets, previously separated from the dry tiles, are oiled and manually placed into the tile machine whereupon they are pushed from their rear end back through the extrusion box. All mechanisms are manually controlled including the hydraulic pallet pushing cylinder. A simple mixer, provides the concrete that has to be produced to a high quality. It is a “multi-profile” machine – different tile types can be produced by it, simply by changing the extrusion head and the aluminum pallets to suit the different tile profile. Different facial tile types can also be produced on the mac

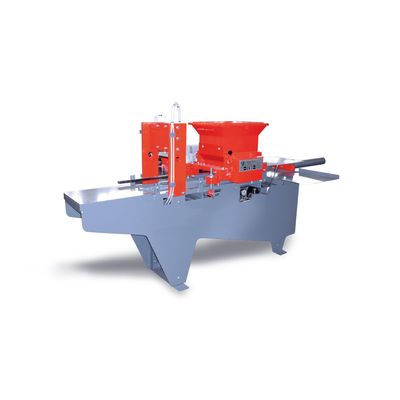

Vortex - Model UNO 10 - Twin Starter Pack Plant

The UNO 10 is an ideal solution for an organisation or entrepreneur that wants to start a new project and at the same time test the market place using minimal capital investment. The semiautomatic production cycle is such that new tiles are formed on the top surface of aluminium pallets that are pushed by a hydraulic cylinder through the extruder machine. On exiting machine the tiles are cut to length by a knife unit. Upgrade to conveyor line and semi-automatic mixer is possible to increase the capacity and level of automation of the line.

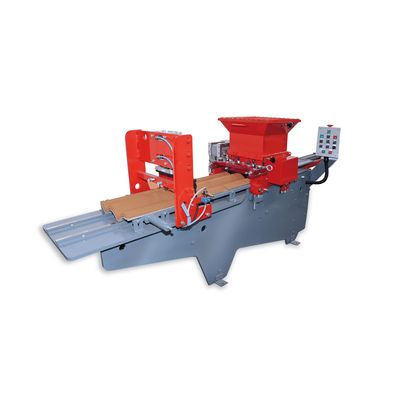

Vortex - Model UNO 20 - Twin Starter Pack Plant

The UNO 20 has an automatic manufacturing cycle. This plant is an ‘inline’ operation that consists of a depalleter, pallet feed conveyor, pallet oiler and the tile extruder machine. The ‘heart’ of the system is an UNO 10 machine that now incorporates an alternating higherspeed automated hydraulic underside palle t pushing mechanism. PLC control system.

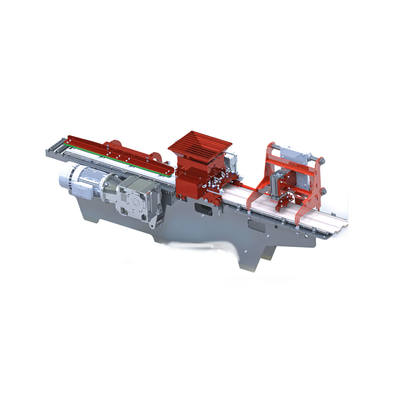

Vortex - Model UNO 30C - Twin Starter Pack Plant

The UNO 30C is the NEW highest capacity plant in the VORTEX UNO range of systems. It is a robust system with a continuous propulsion unit. The UNO 30C extruder machine operates within an automated manufacturing line that incorporates a depalleter, pallet feed conveyor, pallet oiler. The advantage of this system is that the flow of concrete is a continuous one, with benefits in terms of quality and efficiency. The “inline” configuration can be upgraded to a fully automatic one with a complete conveyor loop. PLC control system.

Machinery - Modulo Plants

Vortex - Model Modulo 60 - Velocity Plant

This MODULO system is roof tile plant that has an operational speed up to 60 tiles per minute. It is designed to produce interlocking coloured concrete roof tiles (420 x 330 x approximately 12 mm thick according to the international standards). It is also possible to produce concrete ridge tiles in this plant.

Vortex - Model Modulo 120 - Velocity Plant

The roof tile manufacturing process is basically the same as that of the VORTEX MODULO 60 plant with exception that all the plant and equipment has been designed and quantified to operate at a speed of up to 120 tiles per minute.

Machinery - Rotary-Rack Plants

Vortex - Rotary-Rack Plant

The ROTARY-rack system is an automatic revolving “carousel” steel rack that enables newly manufactured tiles to be equally cured over a minimum pre-set time period, resulting in the early release of the supporting aluminium pallets for re-use in the tile manufacturing process.

Products

Vortex - Roof Tile for Roofing

Dedicated design can be made based on customer needs in order to reduce weight or reduce dimensions. Changing the shape of the pallets and the tooling in the extrusion head will produce a different product profile.

Vortex - Coping-Stones for Flooring

The concrete extrusion system has many advantages compared to the vibro-compression system:

Vortex - Decor Siding for Siding and Flooring

The production of precast concrete parts by wet-casting only requires the use of mould equipment and minimum support equipment. However now more and more automatic production lines are in operation to use the specific advantages of the wet-cast procedure by the optimal use of high efficient production systems.