- Home

- Companies

- VOSS Fluid GmbH

- Products

VOSS Fluid GmbH products

Tube Couplings

Voss NOTCH - Tube Coupling Systems

VOSS 24° tube couplings certified to ISO 8434-1 (DIN 2353) or VOSS 90° tube couplings certified to ISO 8434-3 (ORFS) are suitable for virtually any mobile or stationary hydraulic application areas. Our tube coupling systems are characterized by leak-protection, quality and efficiency.

Hose Fittings

VOSS - Hose Fittings

Hydraulic systems are only as efficient as each individual component. That is why VOSS Fluid places the highest demands on the quality of its hose fittings. With regard to leak and installation proofing as well as versatility and durability. The synergy between VOSS Fluid hose fittings and other VOSS coupling systems guarantees the right fit for any application.

Ready-to-install Cables

VOSS - Thermal Management Cables

Optimum battery temperature control is essential for maximum performance and range in electric and hybrid vehicles. To reliably maintain a constant temperature level, the battery must be cooled or heated accordingly. VOSS solutions include the development and production of ready-to-install cables and their components, such as sensors, valves, distributors, and connection systems.

Measuring Technology

VOSS - Measuring Technology

Pressure testing in hydraulic systems is extremely important for smooth and reliable system operation. Today, measuring couplings are a standard in hydraulic systems and are used frequently. VOSSPointDC measuring couplings enable virtually leak-proof coupling and uncoupling of measuring and testing devices or apparatuses for filling or ventilating. For improved identification the sealing cap is marked in color, which guarantees optimum orientation for the user within the hydraulic system. We redefine safety and handling with the sophisticated design principle behind VOSS measuring couplings. As a standard, the line is coated with the superior VOSS coat zinc-nickel coat.

Valves

VOSS - Hydraulic Valves

VOSS hydraulic valves compliment the broad coupling assortment for simple function sequences in hydraulic control circuits. As a manufacturer of hydraulic valves, we provide a large number of design versions, as well as custom modifications, extra functional details or special customer-specific developments. In accordance with VOSS Fluid quality standards, all valves intended for hydraulic control systems are protected against corrosion with VOSS coat surface protection.

Plug-in Systems

VOSS - Stecksystem for SAE J2044 Connections

VOSS expands the capabilities of AdBlue®, coolant, and thermal management systems with the Stecksystem 241 N / 241 N-SL, enabling connections according to SAE J2044 standards. This new generation diverges from the original Stecksystem 241 with an innovative design for the opening mechanism. The system offers various configurations on the pipeline side: plastic tubing can be connected via spigot or laser welding, while hoses use a hose nipple. It is also available with a secondary lock (241N-SL version) for enhanced security and visual indication, and an electrically heated variant ideal for universal applications. The coupling range includes straight and angled designs, made from robust plastic materials, capable of withstanding pressures up to 10 bar and temperatures ranging from -40°C to +120°C. This system serves sectors including automotive, agricultural, and construction machinery by providing secure, reliable connections in demanding environments.

Pipe Connections

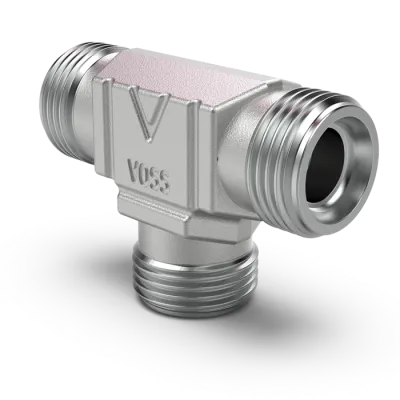

VOSS - 24° Tube Fittings

VOSS offers a comprehensive 24° tube fitting program recognized under ISO 8434-1 and DIN 2353, crafted from both steel and stainless steel. These fittings are renowned for their versatility and cost-effectiveness, offering options in a lightweight 'L' series and a heavy-duty 'S' series, often surpassing international standards. The lighter 'L' series is suitable for many applications, enabling space and weight savings without compromising system integrity. Innovative corrosion protection is achieved with VOSS coat, a zinc-nickel based surface treatment, ensuring durability in harsh environments. VOSS 24° fittings accommodate a broad range of pipe sizes and are compatible with numerous hydraulic applications. They provide user-friendly assembly with reduced friction coefficients, enhancing installation efficiency. Available in versions with NBR or FKM soft seals, these fittings maintain reliable joints even under high pressures up to 800 bar for the 'S' series, meeting the stringent demands of modern engineering designs.

Valves

VOSS - Fuel Valves for Automotive Systems

VOSS offers a comprehensive range of fuel valves integrated into plug systems, tailored for various automotive and industrial applications. The standard valve program includes multi-way switching valves that manually control flow between connected lines, outflow stop valves preventing fuel spillage at disconnected junctions, and check valves opening at specified pressures. These are available in multiple configurations and materials, with a focus on precision and reliability. VOSS valves are constructed from materials like plastic, brass, steel, and stainless steel, catering to specific operating pressures and temperatures. They are essential components in the fuel distribution systems of passenger vehicles, light commercial vehicles, trucks, and buses, providing seamless integration with fuel lines and offering enhanced functionality. The company's offerings extend to customized solutions, providing comprehensive connection components, ensuring efficient and secure fuel routing across various transportation and stationary system applications.

Sensors

VOSS - Integrated Vehicle Pressure Sensors for Air Systems

VOSS has developed a system combining connectors with pressure sensors to enhance the efficiency of pneumatic systems in commercial vehicles. This innovation simplifies the integration of sensors into air systems, particularly in the braking, air suspension, and auxiliary circuits of trucks and buses. The sensors come pre-mounted on connectors, allowing for 360-degree rotation to simplify installation. This design eliminates the need for complex setups involving separate branches, adapters, and mounts. These pressure sensors offer a single connection point for both pneumatic and sensor connections, minimizing space requirements, reducing weight, and improving handling efficiency compared to traditional systems. Technical specifications include a pressure range from 0.85 to 16.85 bar, a supply voltage of 8V to 32V, an output signal of 0.5V to 4.5V, and functionality between -40°C to +100°C. The sensors are validated according to ISO 16750 standards.