- Home

- Companies

- VT Corp Pvt. Ltd.

- Products

VT Corp Pvt. Ltd. products

Packing Machines

Model VTC-ERP–8 - Vertical Impeller Type Electronic Roto Packer (4 to 16 Spout)

Outstanding Features: Micro Processor based stationary and rotary Electronic Packers. Fully automatic Filling & Weighing. Output of the machine is 15 tons/hour/spout for 50 kg bag. Microprocessor based control unit along with advanced PLC system.. Latest stage technology and user friendly designs. Two stage filling (coarse & fine) of the material inside the bag ensures better accuracy in weighments. Uses pre-stitched valve type bags. Hence, no stitching is required after the bags are filled. Same machine can be used for packing cement in paper bag, HDPE bag (woven). Available in 1 to 4 filling spouts in stationary model and 6 to 16 filling spouts in rotary model. Easy availability of spares and after sales service.

Model VTC-VIP-2.3 - Vertical Impeller Type Electronic Stationary Packer

Micro Processor based stationary and rotary Electronic Packers. Fully automatic Filling & Weighing. Output of the machine is 15 tons/hour/spout. Digital weighing system with indicator. Latest technology and user friendly designs. Two stages filling of the material inside the bag ensures better accuracy in weighments. Uses pre-stitched valve type bags. Hence, no stitching is required after the bags are filled. Same machine can be used for packing cement in jute, HDPE (woven), or paper bags (non-laminated). Available in 1 to 6 filling spouts in stationary model and 3 to 12 filling spouts in rotary model. Easy availability of spares and after sales service.

Model VEC - W - Weigh Feeder

We will take this opportunity to introduce VT CORP as a leader in the field of Industrial weighing and bagging machines and material handling equipment for last 40 years. Our heavy duty Weigh Feeder offers accurate weigh feeding of a variety of demanding industrial applications with high feed rates. Its unique design allows the belt to be changed with minimum downtime, and its heavy-duty construction provides larger pulleys and a very sturdy and rugged frame for increased accuracy in high-rate, heavy-duty applications. These features work together to augment the performance of your process and improve your bottom line. Every feeder is designed to meet the specific needs of the application. We work closely with our customers to ensure that each system meets their expectations for performance and dependability. Our weigh feeders can accommodate flow rates up to 2000 TPH, and belt widths up to 2400 mm.

Model VTC-VFFS -1.6 - Vertical Form Fill Seal Machine

Model VTC-VFFS is a Vertical Form Fill Seal packing machine offers speed, accuracy and effciency for flexible packaging of a wide variety of snacks, granules, powders etc. The machine is equipped with load cell based linear weigher for high accuracy in weighing. Machine is also available with volumetric filler like auger/cup-filler.

Electrostatic Precipitator

VT Corp - Model ETP - Electrostatic Tar Precipitator

Electrostatic Tar Precipitator (ETP) is exclusively used for the removal of tar from flue gasses of producer gas plants and coke oven plants.

Single Field ESP

Single field ESP is ESP with only one field (Normally ESP has more has 2 or 3 field). Internal arrangement is same as regular ESP i.e.Rows of collection electrode and discharge electrode with their respective rapping systems. This is ideally used for application like a palm oil mills where the flue gas pass through multicyclone, due to coarser particles are removed and only the final particle is required to be treated in ESP. The dust burdens are very low, hence this single field ESP are used in such applications.

Forced Draft Cooler

What is Forced Draft Cooler? The Forced Draft Cooler is tubular convective type Heat Exchanger used for cooling of hot gases.In Sponge Iron Plants the kiln outlet gases are at approx. 900 to 950 °C. These flue gases cannot be let out to atmosphere as it is and are to be de-dusting. Hence, it is mandatory to provide Dust Collecting system. The major problem of providing the Dust Collecting System is the temperature of the flue gases and it becomes necessary to cool the kiln exhaust gases to around 180 to 220 °C.The best way to accomplish this task is to have air to gas heat exchanger. Although dilution with ambient air / water spray etc. are available for the heat exchanger. Air to gas force draft heat exchanger are the simple, economical & best suited system.

DeNOx

VT Corp - Selective Non-Catalytic Reduction (SNCR)

Selective Non-Catalytic Reduction is a post-combustion technology that is designed to control nitrogen oxides (NOx) emissions from boilers by the injection of ammonia or urea reagents into the flue gas around 1000 °C. At these temperatures the reaction is fast enough for almost complete consumption of the injected chemical within the available time frame without a catalyst to speed up the process. The purpose of the reducing agent is to enable reduction of the NOx species. The resulting product of the chemical reaction is elemental nitrogen (N2) and water (H2O).

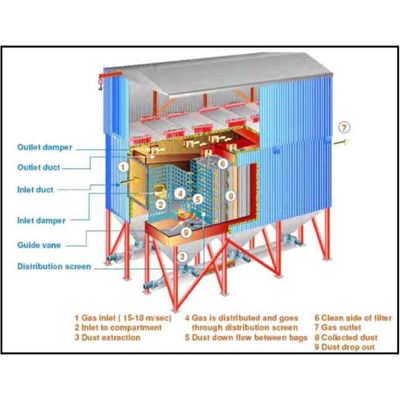

Baghouse / Bag Filters

VT Corp - Baghouse / Bag Filters

VT CORP product range consists of Pulse Jet Bag Filters in an online and offline type model, Insertable type units. Pulse jet Bag filters are the fabric based self-cleaning dry filtration system that removes particulate matter and dust from the surface of the internal by the sequentially controlled burst of the compressed air. According to the Application and process parameters these systems can either be selected in ONLINE and Modular construction-based OFFLINE cleaning mode. VTC filter based systems can control particulate emission or product recovery in most of the industrial applications including broadly Boilers, various types of Furnaces, Kilns, Mills, and various material handling applications and more than 100 + applications.