VV-net products

ROMEO Technology

Model Solano - Suspended Particle Reactor

As soon as the system has reached normal operation temperature, a carrier (1) with the objects is submerged in the suspended particle reactor, as if it were a boiling liquid. The contamination on the objects will essentially convert to gas and fine inorganic powder very quickly, all while most of the energy contained in the contamination helps to heat the reactor. Gas and inorganic powder are carried with the flow through the reactor (2), and led into a dust separation device, which can be a cyclone or a barrier filter (3). The inorganic powder is (4) is collected and can be removed daily, and the cleaned exhaust flow (5) is released into atmosphere.

Model Zonda - Controlled Atmosphere Reactor

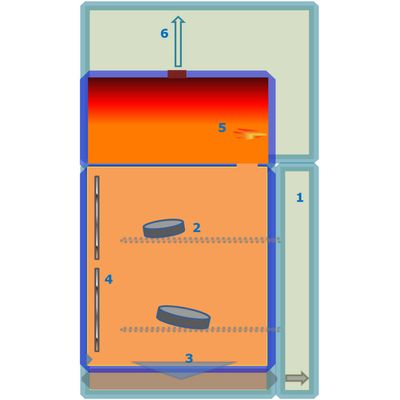

When the door (1) of the controlled atmosphere – cold or preheated - is opened, the parts can be loaded onto the stacking tray (2) which slides out of the unit automatically for easy access. Once closed, the programmed cleaning cycle starts. The process may contain a melting phase to remove most of the polymer or contamination from the delicate parts, in which case the melted material (3) can be removed prior to the start of the real cleaning cycle, or left in the unit to slowly evaporate later in the cycle. The cleaning cycle itself takes typically 1.5 to 3 hours, depending on the parts and the quantity of polymer to be removed. The atmosphere – temperature and oxygen content - in the reactor is permanently controlled to keep temperatures right all the time and to avoid overheating or burning at all times. The reactor is electrically heated (4), and the gases leaving the reactor pass through an ignition and postcombustion chamber (5) to clean the exhaust flow.

Other Technology

VENUS Technology

With our ‘venus’ technology, we bring together all our process expertise, application knowledge, and experience in development of standardized reliable sytems in the niche of ‘conversion and recovery of energy and useful materials from waste’. We take it as our challenge to create and promote economically viable and ecologically sound “local” solutions to dry, recover useful compounds and produce energy from specific waste and sludge streams. It is our ultimate goal to spread the use, and to uncover the immense potential of this long hidden novel Unecco process technology, and to lower scale barriers for ecological and sustainable local solutions with the smallest total carbon footprint and environmental impact.

SCALA Technology

Our ‘scala’ technology has originally been developed in close collaboration with research institutions and industries specialized in green sand aluminum casting technology and rapid prototyping. It has been developed with the intent to play a role in improving the durability of castings and reducing the ecological impact compared to more traditional treatment methods with mechanical shaking stages for de-coring and mould sand removal and huge furnaces and quench tanks for turning a green sand casting from the fresh casting into a finished part ready to be mounted in its final destination.

CARAT Technology

With our ‘carat’ technology, we bring together all our process expertise, application knowledge, and experience in development of standardized reliable sytems in the niche of ‘catalytic, absorptive and reactive hot gas cleaning’.Having been involved in a pioneer role bringing ceramic filters for emission control applications on the market back in the nineties, we have gained valuable experience in design and conceptual creation of hot gas cleaning techniques. We have taken the road of specializing in all-dry solutions, and in stretching the barriers for absorptive dry acid gas cleaning, often built onto complete turn-key thermal processing systems we have designed and supplied by numbers, from large to very small.