Weidner Wassertechnik GmbH products

Water Treatment Chemicals

It is ideal for water conditioning processes to be managed without additional chemicals. In most cases the use of chemicals cannot be avoided but it can be done more environmentally friendly with increased profit. Therefore our team provides new and better agents for cost efficient water conditioning. The water conditioning chemicals of the Weidner Wassertechnik GmbH serve the purpose of optimization and conservation of value of your plant. We are always trying to minimize addition quantities for economical and ecological reasons.

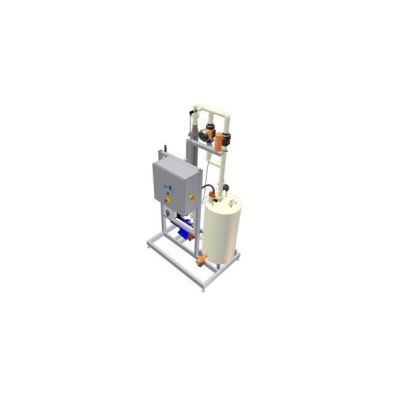

Dosing Plants

We build, plan and maintain dosing plants and related components for a variety of different dosing applications. A competent advice regarding the right material selection for dosing head and dosing pipe is self-evident. Our dosing plants can be used flexibly and ensure a high operational safety at any time.

Ion Exchangers

Well and surface water contains different concentrations of solved hardness builders depending on the geological conditions. This carbonate hardness (calcium and magnesium carbonate) is commonly called lime. The carbonate hardness of the water is basically not hazardous to health. But in most cases unwanted deposits are created in heated pipings and heat exchangers which lead to stark reductions of the heat transfer and thus to an unnecessary waste of energy. We use the ion exchange method for an efficient and economical water softening. In case of the ion exchange method products and methods belong directly and inseparably together and have to be attuned perfectly to each other. Ion exchange methods make it possible to remove all ions which are not wanted in the water and synthetically replace them with other ions.

Membrane technology

The separation of substances with the help of membrane technology is a physical separation process. The big advantage of the membrane technology compared to other separation processes is based on the fact that to be separated materials can be changed neither biologically and chemically nor thermally. The membrane technology opens up new possibilities and increasingly replaces existing technologies like concentration by evaporation or chemical processes resp. can be combined with them. Basically many different membranes with different selectivities are available. In the membrane technology one distinguishes between reverse osmosis, nano filtration and micro filtration.

Automatization

The profitability and the process success for the addition of treatment products in the water conditioning are crucially influenced by the optimal dosage amount. This is dependent the continuously changing water ingredients. Therefore we have automatized the measuring of suitable parameters as well as the realization into a highly efficient dosing strategy for you and can individually customize our system to your needs. The success of water conditioning by addition of treatment products or through an extreme water conditioning is significantly depending on the chemical composition of the water and on the concentration of the added treatment products.

Parameters

Our analysis machines are available in two variations (Wetronic A 1 and Wetronic A 2). The following parameters can be analyzed: Ortho-phosphate, total phosphate, molybdenum, sulfite, remaining hardness (total hardness), silicates, iron, nickel, chlorine (free and total chlorine), acid capacity, hydrazine, complex builders (NTA, EDTA, IDS) and hydrogen peroxide. Basically every ion sensitive probe can be connected to our system. Analysis processes according to addition methods or direct methods with automatic calibration can be developed if they are not already in our software archive.

Filtration

Model Sand Filter - Filtration Product

Our space saving one-column gravel filter plants for the continuous filtration of industrial, well and process water is perfectly suitable for the hard day-to-day practice because of its simple process technology and the manufacturing quality. The lower the filtration speed the higher the deposition rate. Basically deposition rates of up to >10 µm can be achieved. The process can be optimized further with the help of flocking agents. Our standard delivery program includes gravel filters with a throughput of 4 to 12 m³/h. By grouping of several filters it is possible to achieve even higher throughput performances and at the same time it creates a redundant system.

Model Cartridge Filter - Filtration Product

Our durable cartridge filters can be used in many different ways and have a good chemical resistance. According to your individual requirements different filtration materials like wrapping cartridge, activated carbon filters or membrane filters (sterile filters) are used. The liquid stream in the candle filter is lead through the cartridge from outside to inside. The pores of the candle filter are getting finer on the inside. This guarantees a very high dirt absorption capacity. An integrated grab handle on the upper end of the cartridge makes it possible to easily change the cartridge. The connections for manometers allow a controlled operating of the filters with the help of the difference pressure. Wrapped cartridge filters are used as filter elements. The material selection is dependent on the operating temperatures.

Model Deironing - Filtration Product

Incrustations in raw networks or staining of the water through iron oxide resp. manganese oxide hydrate belong to the unpleasant phenomena in drinking water installations. Aside from operational disturbances, rough piping walls support the formation of biofilms with the corresponding health risks. The professional solution offers of the Weidner Wassertechnik GmbH have provided a hygienic proper water quality for many years and support you with the conservation of value of your drinking water installations as well as a smooth operating. Disturbing iron and manganese ions in the well water can be removed economically through our compact and low maintenance technology. We offer systems which are specially customized for the needs of private, agricultural as well as other industrial areas. Because of the compact and simple design an installation can also be done in places where not much space is available.