Dynatec Systems Inc.

- Home

- Companies & Suppliers

- Dynatec Systems Inc.

- Downloads

- The Dynatec Difference Containerized ...

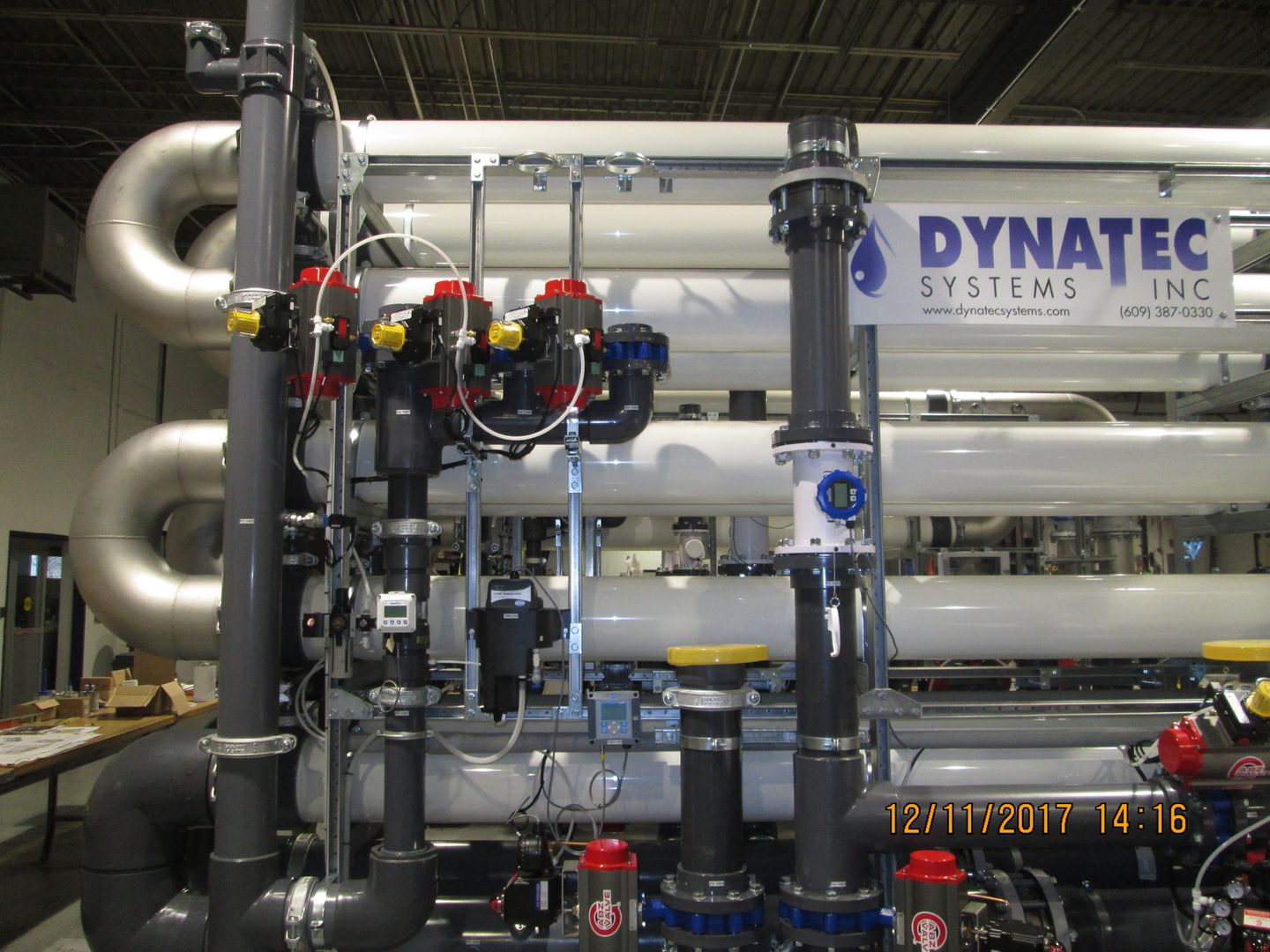

The Dynatec Difference Containerized Membrane Systems Dynatec provides completely packaged membrane systems installed in a shipping conta

The Dynatec Difference Containerized Membrane Systems

Dynatec provides completely packaged membrane systems

installed in a shipping container:

Easy low-cost installation

No building required

Easily moved to other locations

Quick and easy mobilization

Microfiltration, Ultrafiltration, Nanofiltration, Reverse Osmosis

Dynatec has extensive experience in the supply of membrane systems, for

sanitary and industrial applications.

UF treatment from 10,000—200,000 gpd and RO treatment from 10,000– 200,000 gpd in

one container:

Needs minimal operator attention

Uses long-lasting tubular membrane

Produces high quality purified water

Significant Savings

Small footprint

Complete prepackaged system

Remote monitoring possible

Easy maintenance

Automatic operation

Low sludge production

Long membrane life

Technology Benefits

Membrane separation

system uses long-lasting

tubular ultrafiltration (UF)

membranes

Simple mechanical process

Consistent high quality water

Ability to reuse purified water

Low operating costs

Unattended operation

Minimal sludge disposal costs

Safe odor free environment

Semi automatic cleaning

Services Provided

System Design

Equipment and Installation

Operator Training

Maintenance Contract

Treatability and Pilot testing

Design-Build-Own-Operate-

Maintain

Ultrafiltration is a pressure-driven process that can remove

essentially all suspended matter from water and wastewater:

Emulsified oils

Metal

Colloids

Emulsions

Dispersed material

Suspended solids

Large molecular-weight matter

Ultrafiltration is capable of concentrating:

Bacteria

Some proteins

Some dyes

Oils

Colloidal or emulsified components

Suspended solids

Metals

Ultrafiltration excels at the clarification of solutions

containing:

Suspended solids

Bacteria—MBR

High concentrations of macromolecules including:

Oil and water

Fruit juice

Milk

Electro-coat paints

Pharmaceuticals

Poly-vinyl alcohol and indigo

RO systems typical applications include:

Preparation of high-purity water for the semi-conductor

industry

Reduction of dissolved solids and organics in wastewater

reuse applications

Concentration of fruit juices

Recovery of aircraft deicing fluids

Adjustment of alcohol content in wine and beer

(e.g. production of low alcohol beers)

Reduction of dissolved solids and color in landfill leachate

treatment for ground our surface water discharge

Two modular containers side by side

Most popular related searches